eBook - ePub

Complete Guide to Making Wooden Clocks, 3rd Edition

37 Woodworking Projects for Traditional, Shaker & Contemporary Designs

John A. Nelson

This is a test

Compartir libro

- 250 páginas

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

eBook - ePub

Complete Guide to Making Wooden Clocks, 3rd Edition

37 Woodworking Projects for Traditional, Shaker & Contemporary Designs

John A. Nelson

Detalles del libro

Vista previa del libro

Índice

Citas

Información del libro

Learn how to construct a variety of traditional, Shaker, and contemporary clocks, with plans, parts lists, and instructions for 37 timepieces, including grandfather clocks, mantel clocks, and desk clocks.Complete Guide to Making Wooden Clocks, 3rd Editionalso includes a bonus pattern pack with scroll saw project templates.

Preguntas frecuentes

¿Cómo cancelo mi suscripción?

¿Cómo descargo los libros?

Por el momento, todos nuestros libros ePub adaptables a dispositivos móviles se pueden descargar a través de la aplicación. La mayor parte de nuestros PDF también se puede descargar y ya estamos trabajando para que el resto también sea descargable. Obtén más información aquí.

¿En qué se diferencian los planes de precios?

Ambos planes te permiten acceder por completo a la biblioteca y a todas las funciones de Perlego. Las únicas diferencias son el precio y el período de suscripción: con el plan anual ahorrarás en torno a un 30 % en comparación con 12 meses de un plan mensual.

¿Qué es Perlego?

Somos un servicio de suscripción de libros de texto en línea que te permite acceder a toda una biblioteca en línea por menos de lo que cuesta un libro al mes. Con más de un millón de libros sobre más de 1000 categorías, ¡tenemos todo lo que necesitas! Obtén más información aquí.

¿Perlego ofrece la función de texto a voz?

Busca el símbolo de lectura en voz alta en tu próximo libro para ver si puedes escucharlo. La herramienta de lectura en voz alta lee el texto en voz alta por ti, resaltando el texto a medida que se lee. Puedes pausarla, acelerarla y ralentizarla. Obtén más información aquí.

¿Es Complete Guide to Making Wooden Clocks, 3rd Edition un PDF/ePUB en línea?

Sí, puedes acceder a Complete Guide to Making Wooden Clocks, 3rd Edition de John A. Nelson en formato PDF o ePUB, así como a otros libros populares de Tecnología e ingeniería y Oficios técnicos y manufactureros. Tenemos más de un millón de libros disponibles en nuestro catálogo para que explores.

Información

CHAPTER 1

A Brief History of Clocks

The theory behind time-keeping can be traced back to the astronomer Galileo. In 1580, Galileo, who is well-known for his theories on the universe, observed a swinging lamp suspended from a cathedral ceiling by a long chain. As he studied the swinging lamp, he discovered that each swing was equal and had a natural rate of motion. Later he found this rate of motion depended upon the length of the chain. For years he thought of this, and in 1640, he designed a clock mechanism incorporating the swing of a pendulum. Unfortunately, he died before actually building his new clock design.

In 1656, Christiaan Huygens incorporated a pendulum into a clock mechanism. He found that the new clock kept excellent time. He regulated the speed of the movement, as it is done today, by moving the pendulum bob up or down: up to “speed-up” the clock and down to “slow-down" the clock.

Christiaan’s invention was the boon that set man on his quest to track time with mechanical instruments.

EARLY MECHANICAL CLOCKS

Early mechanical clocks, probably developed by monks from central Europe in the last half of the thirteen century, did not have pendulums. Neither did they have dials or hands. They told time only by striking a bell on the hour. These early clocks were very large and were made of heavy iron frames and gears forged by local blacksmiths. Most were placed in church belfries to make use of existing church bells.

Small domestic clocks with faces and dials started to appear by the first half of the fifteenth century. By 1630, a weight-driven lantern clock became popular in the homes of the very wealthy. These early clocks were made by local gunsmiths or locksmiths. Clocks became more accurate when the pendulum was added in 1656.

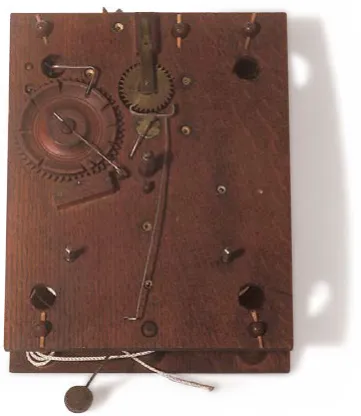

Early clock movements were mounted high above the floor on shelves because they required long pendulums and large cast-iron descending weights. These clocks were nothing more than simple mechanical works with a face and hands and were called “wags-on-the-wall.” Long-case clocks, or tall-case clocks, actually evolved from the early wags-on-the-wall clocks. They were nothing more than wooden cases added to hide the unsightly weights and cast-iron pendulums.

JOHN HARRISON (1693–1776)

Little is known about this man, the one person who, I think, did the most for clock-making. John was an English clockmaker, a mechanical genius, who devoted his life to clock-making. He accomplished what Isaac Newton, known for his theories on gravity, said was impossible.

John Harrison was born March 24, 1693, in the English county of Yorkshire. John learned woodworking from his father, but taught himself how to build a clock. He made his first clock in 1713 at the age of 19. It was made almost entirely of wood with oak wheels (gears). In 1722 he constructed a tower clock for Brocklesby Park. That clock has been running continuously for over 270 years.

One year later, on July 8, 1714, England offered £20,000 (approximately 12 million dollars) to anyone whose method proved successful in measuring longitude. Such a device was desperately needed by navigators of sailing vessels. Sailors during this time were literally lost at sea as soon as they lost sight of land. One man, John Harrison, felt longitude could be measured with a clock.

John Harrison

During the summer of 1730, John started work on a clock that would keep precise time at sea—something no one had yet been able to do with a clock. In five years he had his first model, H-1. It weighted 75 pounds and was four feet tall, four feet wide and four feet long. To prove his theory, John built H-2, H-3 and H-4.

His method of locating longitude by time was finally accepted and he won the prize. It took him over 40 years. Today, his perfect timekeeper is known as a chronometer.

CLOCKS IN THE COLONIES

In the early 1600s, clocks were brought to the colonies by wealthy colonists. Clocks were found only in the finest of homes. Most people of that time had to rely on the church clock on the town common for the time of day.

Most early clockmakers were not skilled in woodworking, so they turned to woodworkers to make the cases for them. These early woodworkers employed the same techniques used on furniture of the day. In 1683, immigrant William Davis claimed to be a “complete” clockmaker. He is considered to be the first clockmaker in the new colony.

Great horological artisans immigrated to the New World by 1799. Most of these early artisans settled in populous centers such as Boston, Philadelphia, New York, Charleston, Baltimore and New Haven.

Clock-making grew in all areas of the eastern part of the colonies. The earliest and most famous clockmakers from Philadelphia were Samuel Bispam, Abel Cottey and Peter Stretch. The most famous clockmaker was Philadelphia’s David Rittenhouse. David succeeded Benjamin Franklin as president of the American Philosophical Society and later became Director of the United States Mint.

Most Early American clocks had wooden gears, as brass was very expensive and hard to obtain.

NINETEENTH CENTURY GRANDFATHER CLOCKS

Inexpensive tall-case clocks were made in quantity and became more affordable after 1800. The clock-making industry spread to the northeastern states. In Massachusetts, Benjamin and Ephram Willard became famous for their exceptionally beautiful long-case clocks. In Connecticut, mass-produced long-case clocks were developed by Eli Terry.

In early days, almost all clock cases were made by local cabinetmakers. A firm that specialized in clock works fashioned the wood or bronze works. Cabinetmakers engraved or painted their names on the dial faces, thereby taking claim for the completed clocks.

With the advent of the Industrial Revolution, regular factory working hours and the introduction of train schedules, standardized timekeeping became a necessity. Clock-making moved to the forefront.

Wooden movements were abandoned in 1840 and 30-hour brass movements became popular. They were easy to make and inexpensive. Spring-powered movements were developed soon after. A variety of totally new and smaller clock cases appeared on the market.

NINETEENTH-CENTURY MANUFACTURERS

Clock manufacturers were mostly individual clockmakers of family-owned companies. After 1840 however, Chauncy Jerome built the largest clock factory in the United States. He started shipping clocks all over the world. The Jerome Clock Company motivated the organization of the Ansonia Clock Company and the Waterbury Clock Company. These three companies, along with Seth Thomas Company, the E. N. Welch Company, the Ingraham Clock Company, and the Gilbert Clock Company, became the major producers of clocks in the nineteenth century. There were over 30 clock factories in this country by 1851. From 1840 up to 1890, millions of clocks were produced in this country, but unfortunately, very few still exist intact today.

Elias Ingraham

Elias was born in 1805 in Marlborough, Connecticut. He served a 5-year apprenticeship in cabinetmaking in the early 1820s. By 1828, at the age of 23, Elias was designing and building clock cases for George Mitchell. When he was 25 years old, he worked for the Chauncey and Lawson Ives Clock Company, which was still designing and building clock cases.

Elias formed a new company with his brother Andrew in 1852 called the E. and A. Ingraham and Company, but 4 years later, it went bankrupt. A year later he formed his own company with his son, Edward. Changing the name to E. Ingraham and Company, the business began ...