Operator's Guide to Process Compressors

Robert X. Perez

- English

- ePUB (apto para móviles)

- Disponible en iOS y Android

Operator's Guide to Process Compressors

Robert X. Perez

Información del libro

The perfect primer for anyone responsible for operating or maintaining process gas compressors.

Gas compressors tend to be the largest, most costly, and most critical machines employed in chemical and gas transfer processes. Since they tend to have the greatest effect on the reliability of processes they power, compressors typically receive the most scrutiny of all the machinery among the general population of processing equipment. To prevent unwanted compressor failures from occurring, operators must be taught how their equipment should operate and how each installation is different from one another.

The ultimate purpose of this book is to teach those who work in process settings more about gas compressors, so they can start up and operate them correctly and monitor their condition with more confidence. Some may regard compressor technology as too broad and complex a topic for operating personnel to fully understand, but the author has distilled this vast body of knowledge into some key, easy to understand lessons for the reader to study at his or her own pace.

This groundbreaking new work is a must-have for any engineer, operator, or manager working with process compressors.

The main goals of this book are to:

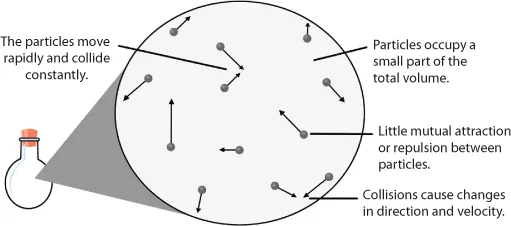

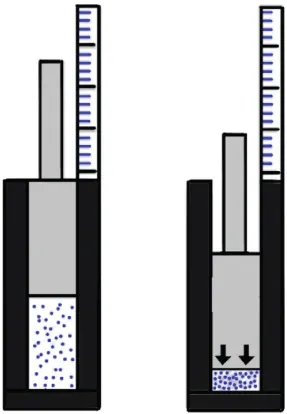

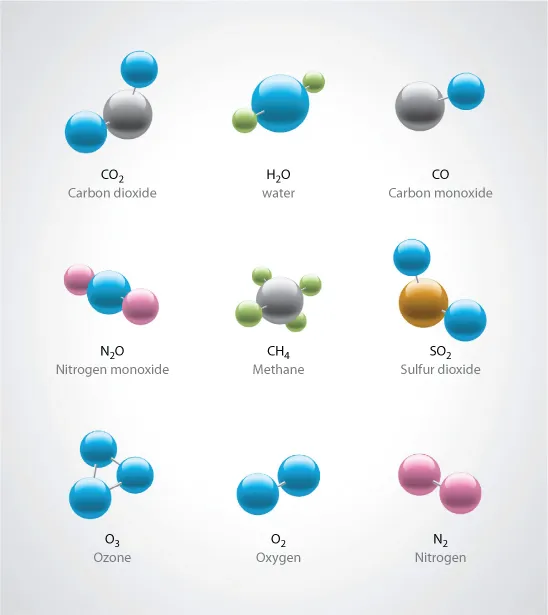

- Explain important theories and concepts about gases and compression processes with a minimum of mathematics

- Identify key compressor components and explain how they affect reliability

- Explain how centrifugal compressors, reciprocating compressors, and screw compressors function.

- Explain key operating factors that affect reliabilityIntroduce the reader to basic troubleshooting methodologies

- Introduce operators to proven field inspection techniques

- Improve the confidence of personnel operating compressors by teaching them the basics of compressor theory

- Improve compressor reliability plantwide by teaching operating and inspection best practices

- Improve communication between operating and supporting plant personnel by providing a common vocabulary of compressor terms

- Help processing plants avoid costly failures by teaching operators how to identify early compressor issues during field inspections

Preguntas frecuentes

Información

Chapter 1

Introduction to Gases