1.A The role of inventory management

The success of a venture depends on its ability to provide services to customers or users and remain financially viable. For an organisation that supplies goods to its customers, the major activity is to have suitable products available at an acceptable price within a reasonable timescale. Many parts of a business are involved in setting up this situation. Initially it is the marketing and design departments, then purchasing and, in some cases, manufacture is involved. For an item which is already in the marketplace, the main activity is providing a continuity of supply for customers.

Inventory control is the activity that organises the availability of items to customers. It co-ordinates the purchasing, manufacturing and distribution functions to meet marketing needs. This role includes the supply of current sales items, new products, consumables, spare parts, obsolescent items and all other supplies.

Inventory enables a company to support the customer service, logistic or manufacturing activities in situations where purchase or manufacture of the items is not able to satisfy the demand. This could arise either because of the speed of purchasing, or because manufacturing is too protracted, or because the quantities demanded cannot be provided without stocks (i.e. the demand rate exceeds the maximum supply rate).

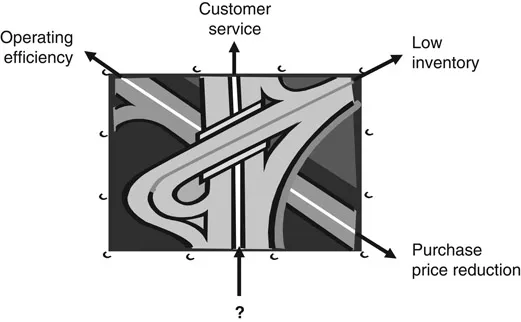

Stock control exists at a crossroads in the operations of a company (Figure 1.1). Many activities depend upon having the correct level of stock, but the definition of the term ‘correct level’ varies depending upon who defines it. Stock control is definitely a balancing act between the conflicting requirements of the company, and the prime reason for the development of inventory management is to resolve this conflict in the best interests of the business. A conventional supply organisation will have many departments, including sales, purchasing, finance, quality assurance, contracts and general administration. In some cases there will also be manufacturing, distribution or support services, or a variety of industry-specific activities. Each of these has a biased view of the ‘correct level’.

Figure 1.1 Which direction?

The strategic view of inventory management is that it exists for three reasons:

- To cover up the mismatch between supply and demand processes.

- To minimise the risk of failure to supply.

- To minimise the overall costs in the supply chain.

Inventory separates demand from supply, so that users are not affected by the limitations in the supply chain.

Inventory is the fluid that lubricates the wheels of the supply chain.

The aim is to provide the most beneficial solution to the end users and the providers within the supply chain. This could include short-term profit, long-term growth or other advantages, such as market retention. Where the strategy can include co-ordination along the supply chain, stockholding can be structured to provide maximum availability and minimum inventory, consistent with minimum risk.

The inventory manager needs to understand their colleagues’ differing views of the requirements for inventory.

Sales consider that good stock control enables the company to have available any item which will meet immediate sales for as large a quantity as demanded: this requires large stocks. For service companies where parts are required, the control of stock at the customer interface is traditionally left with the person carrying out the service, which normally causes stock-outs and panic supply. For efficient distribution, shipments should be in full loads, which can lead to high stock levels. A compromise has to be reached.

Inventory control keeps balancing conflicting requirements.

Purchasing consider that inventory is a buffer enabling goods to be purchased ahead so that optimum prices can be obtained. Buying items in bulk often reduces the purchase price and it also reduces the workload within the purchasing department. The stores are a means of keeping bulk purchase items after buying advantageously.

Finance departments have problems with stock because it consumes vast amounts of working capital and upsets the cash flow. One benefit of stock from a financial standpoint is that provisions can be made in case the stock turns out to be unsaleable, and this value can be adjusted to modify the profit figure in times of good or bad financial results. However, the existence of these provisions in the first place is detrimental to the company’s finances.

Reliability and consistency are the keys to effective inventory management.

Quality management often causes delays in processing materials and increases in recording, and therefore greater inventory. Applying improved quality management systems can avoid this problem by ensuring consistent operation of supply and processes, rather than the products. Businesses should review whether any quality checking can be eliminated by co-ordinating with suppliers.

Logistics view inventory as an advantage in maintaining full use of distribution so that load size can be optimised and distribution costs reduced.

General management see stock control, rightly, as a source of information. Some management consider that they should be able to use stock control to give an immediate supply of information, statistics and forecasts. This can result in large amounts of unstructured work collecting, analysing and providing information.

1.A.1 Manufacturing

The traditional view of manufacturing companies has been that large batches reduce direct production costs. Manufacturing management tend to aim more for plant and labour efficiency and allow high stocks in order to avoid the disruptions caused by shortages, breakdowns and changing customer demand.

Good stock controllers (or materials management) will keep the stock down as long as they are responsible for stock levels of everything, including raw materials, finished and semi-finished stocks, consumables, tools, work on the shop floor.

Do not confuse high stock with good availability.

The focus is now on producing variety, ideally at the same rate as the end user is consuming the items. For manufacturing, batch size is often linked to set-up (changeover) time, which is mistakenly accounted for as a direct cost instead of an overhead. Lean supply has led the way to providing low inventory with low operating costs. Continuous improvement in quality, reliability, delivery frequency and processes reduces inventory and enhances customer service. Gradual changes led by operational people (known as the kaizen approach) help to maintain competitiveness; for example, a change from planning using MRP (material requirements planning; see Chapter 14) to using kanban (see Chapter 6).

The responsibility for maintaining the correct balance is normally left to inventory management. (The actual job title could be controller or manager of materials, inventory or supply chain, or stock planner, or even considered within purchasing, warehouse or logistics in small organisations.) Companies should be careful that inventory is not left in a gap between supply and sales. The proper process is:

| |

Demand for the products varies as a result of changes in market and financial forces. The amount and type of stock control vary in tune with this. Stock control is a dynamic activity, and the successful inventory manager has to ensure that the balance is kept right. This requires both communications skills and professional inventory techniques. Operating methods should be revised continuously to reflect the changes: systems should be altered to suit new situations and operating policies.