eBook - ePub

Handbook of Petroleum Refining

James G. Speight

This is a test

Partager le livre

- 769 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

eBook - ePub

Handbook of Petroleum Refining

James G. Speight

Détails du livre

Aperçu du livre

Table des matières

Citations

À propos de ce livre

Petroleum refining involves refining crude petroleum as well as producing raw materials for the petrochemical industry. This book covers current refinery processes and process-types that are likely to come on-stream during the next three to five decades. The book includes (1) comparisons of conventional feedstocks with heavy oil, tar sand bitumen, and bio-feedstocks; (2) properties and refinability of the various feedstocks; (3) thermal processes versus hydroprocesses; and (4) the influence of refining on the environment.

Foire aux questions

Comment puis-je résilier mon abonnement ?

Il vous suffit de vous rendre dans la section compte dans paramètres et de cliquer sur « Résilier l’abonnement ». C’est aussi simple que cela ! Une fois que vous aurez résilié votre abonnement, il restera actif pour le reste de la période pour laquelle vous avez payé. Découvrez-en plus ici.

Puis-je / comment puis-je télécharger des livres ?

Pour le moment, tous nos livres en format ePub adaptés aux mobiles peuvent être téléchargés via l’application. La plupart de nos PDF sont également disponibles en téléchargement et les autres seront téléchargeables très prochainement. Découvrez-en plus ici.

Quelle est la différence entre les formules tarifaires ?

Les deux abonnements vous donnent un accès complet à la bibliothèque et à toutes les fonctionnalités de Perlego. Les seules différences sont les tarifs ainsi que la période d’abonnement : avec l’abonnement annuel, vous économiserez environ 30 % par rapport à 12 mois d’abonnement mensuel.

Qu’est-ce que Perlego ?

Nous sommes un service d’abonnement à des ouvrages universitaires en ligne, où vous pouvez accéder à toute une bibliothèque pour un prix inférieur à celui d’un seul livre par mois. Avec plus d’un million de livres sur plus de 1 000 sujets, nous avons ce qu’il vous faut ! Découvrez-en plus ici.

Prenez-vous en charge la synthèse vocale ?

Recherchez le symbole Écouter sur votre prochain livre pour voir si vous pouvez l’écouter. L’outil Écouter lit le texte à haute voix pour vous, en surlignant le passage qui est en cours de lecture. Vous pouvez le mettre sur pause, l’accélérer ou le ralentir. Découvrez-en plus ici.

Est-ce que Handbook of Petroleum Refining est un PDF/ePUB en ligne ?

Oui, vous pouvez accéder à Handbook of Petroleum Refining par James G. Speight en format PDF et/ou ePUB ainsi qu’à d’autres livres populaires dans Scienze fisiche et Chimica. Nous disposons de plus d’un million d’ouvrages à découvrir dans notre catalogue.

Informations

Section II

Refining

7 | Pretreatment and Distillation |

7.1 INTRODUCTION

Petroleum in the unrefined state is of limited value and of limited use. Refining is required to produce products that are attractive to the marketplace. Thus, petroleum refining is a series of integrated steps by which the crude oil is converted into salable products with the desired qualities and in the amounts dictated by the market (Speight and Ozum, 2002; Parkash, 2003; Hsu and Robinson, 2006; Gary et al., 2007; Speight, 2014a). In fact, a refinery is essentially a group of manufacturing plants that vary in number with the variety of products produced. Refinery processes must be selected and products manufactured to give a balanced operation. Crude oil must be converted into products according to the demand for each.

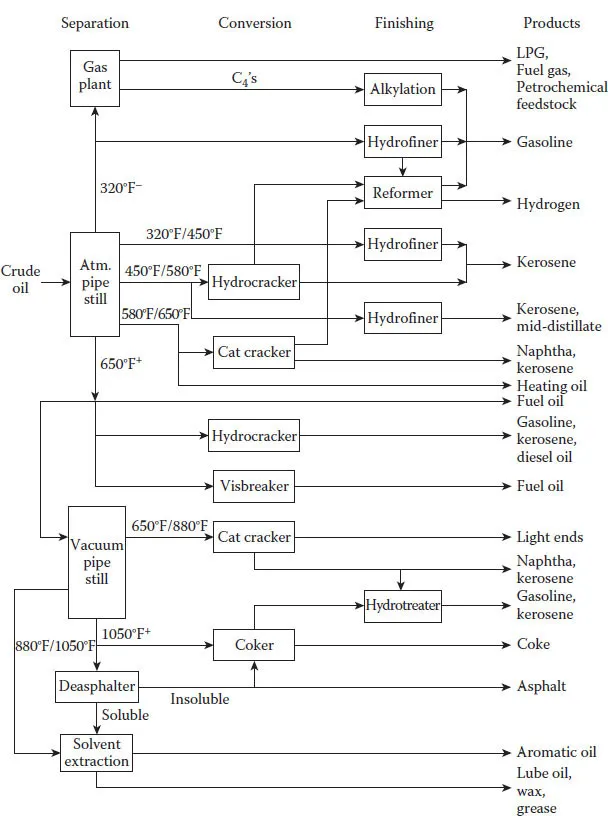

The petroleum refinery of the current century is a much more complex operation (Figure 7.1) than those refineries of the early 1900s and even of the immediate years following World War II (Jones, 1995; Speight, 2011, 2014a). Early refineries were predominantly distillation units, perhaps with ancillary units to remove objectionable odors from the various product streams. The refinery of the 1930s was somewhat more complex but was essentially a distillation unit (Speight, 2014a), but at this time cracking and coking units were starting to appear in the scheme of refinery operations. These units were not what we imagine today as a cracking and coking unit but were the forerunners of today’s units. Also at this time, asphalt was becoming a recognized petroleum product. Finally, current refineries (Figure 7.1) are a result of major evolutionary trends and are highly complex operations. Most of the evolutionary adjustments to refineries have occurred during the decades since the commencement of World War II. In the petroleum industry, as in many other industries, supply and demand are key factors in efficient and economic operation. Innovation is also a key.

A refinery is an integrated group of manufacturing plants (Figure 7.1) that vary in number with the variety of products produced. Refinery processes must be selected and products manufactured to give a balanced operation: that is, crude oil must be converted into products according to the rate of sale of each. For example, the manufacture of products from the lower-boiling portion of petroleum automatically produces a certain amount of higher-boiling components. If the latter cannot be sold as, say, heavy fuel oil, they accumulate until refinery storage facilities are full. To prevent the occurrence of such a situation, the refinery must be flexible and able to change operations as needed. This usually means more processes to accommodate the ever-changing demands of the market (Speight and Ozum, 2002; Parkash, 2003; Hsu and Robinson, 2006; Gary et al., 2007; Speight, 2014a). This could be reflected in the inclusion of a cracking process to change an excess of heavy fuel oil into more gasoline with coke as the residual product or inclusion of a vacuum distillation process to separate the heavy oil into lubricating oil stocks and asphalt.

Thus, to accommodate the sudden changes in market demand, a refinery must include the following: (1) all necessary nonprocessing facilities; (2) adequate tank capacity for storing crude oil, intermediate, and finished products; (3) a dependable source of electrical power; (4) material-handling equipment; (5) workshops and supplies for maintaining a continuous 24 hours/day, 7 day/week operation; (6) waste disposal and water-treating equipment; and (7) and product-blending facilities (Speight and Ozum, 2002; Parkash, 2003; Hsu and Robinson, 2006; Gary et al., 2007; Speight, 2014a).

Petroleum refining is a very recent science and many innovations have evolved during the twentieth century. The purpose of this chapter is to illustrate the initial processes that are applied to a feedstock in a refinery. The first processes (desalting and dewatering) focus on the cleanup of the feedstock, particularly the removal of the troublesome brine constituents (Burris, 1992). This is followed by distillation to remove the volatile constituents with the concurrent production of a residuum that can be used as a cracking (coking) feedstock or as a precursor to asphalt. Current methods of bitumen processing (Speight, 2000, 2014a) involve direct use of the bitumen as feedstock for delayed or fluid coking (Chapter 8). Other methods of feedstock treatment that involve the concept of volatility are also included here even though some of the methods (such as stripping, rerunning, and the like) might also be used for product purification. However, the distillation step is a viable step that produces additional valuable high-boiling fractions from the bitumen.

FIGURE 7.1 General schematic of a refinery.

7.2 DEWATERING AND DESALTING

Even though distillation is, to all appearances, the first step in crude oil refining, it should be recognized that crude oil that is contaminated by salt water either from the well or during transportation to the refinery must be treated to remove the emulsion (Burris, 1992; Abdel-Aal et al., 2016). If salt water is not removed, the materials of construction of the heater tubes and column intervals are exposed to chloride ion attack and the corrosive action of hydrogen chloride, which may be formed at the temperature of the column feed.

Most crude oils contain traces of salt through the salt water produced with the crude feedstock (Speight, 2000, 2014a; Speight and Ozum, 2002; Parkash, 2003; Hsu and Robinson, 2006; Gary et al., 2007). Desalting operations are necessary to remove salt from the brines that are present with the crude oil after recovery (Abel-Aal et al., 2016). The salt can decompose in the heater to form hydrochloric acid and cause corrosion of the fractionator overhead equipment. In order to remove the salt, water is injected into the partially preheated crude, and the stream is thoroughly mixed so that the water extracts practically all the salt from the oil. The mixture of oil and water is separated in a desalter, which is a large vessel in which the water settles out of the oil, a process that may be accelerated by the addition of chemicals or by electrical devices. The salt-laden water is automatically drained from the bottom of the desalter. Failure to remove the brine to acceptable levels can result in unacceptable levels of hydrogen chloride produced during refining. The hydrogen chloride will cause corrosion to equipment even to the point of weakening the equipment and causing fires and explosions.

Generally, removal of this unwanted water has been fairly straightforward, involving wash tanks or a heater. Removal of this same water along with salt concentration reduction presents a completely different set of problems. These can be overcome with relative ease if the operator is willing to spend many thousands of dollars each year for water, fuel, power, and chemical additives. Conversely, if some time is spent in the initial design stages to determine the best methods for water removal to achieve lower bottom sediment and water (BS&W) remnants, mixing, and injection, then a system can be designed that will operate at a greatly reduced annual cost. In most cases, yearly savings on operational expenses will pay for the complete installation in 1–3 years.

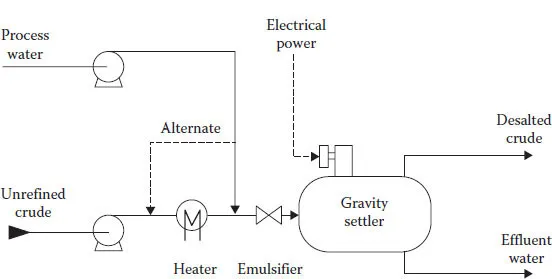

The practice of desalting crude oil is an old process and can occur at the wellhead or (depending on the level of salt in the crude oil) at the refinery (Speight, 2000, 2014a; Speight and Ozum, 2002; Parkash, 2003; Hsu and Robinson, 2006; Gary et al., 2007). Indeed, refineries have been successfully desalting crude oil to less than 5 lb per thousand bbl for many years, and mechanical and electrostatic desalting have been improved greatly. However, very little attention has been given to the use of dilution water, probably due to the general availability of both freshwater and wastewater in and near refineries. Three general approaches have been taken to the desalting of crude petroleum (Figure 7.2). Numerous variations of each type have been devised, but the selection of a particular process depends on the type of salt dispersion and the properties of the crude oil.

The salt or brine suspensions may be removed from crude oil by heating (90°C–150°C, 200°F–300°F) under pressure (50–250 psi) that is sufficient to prevent vapor loss and then allowing the material to settle in a large vessel. Alternatively, coalescence is aided by passage through a tower packed with sand, gravel, and the like.

The common removal technique is to dilute the original brine with fresher water so that the salt content of water that remains after separation treatment is acceptable, perhaps 10 lb per thousand barrels of crude oil, or less. In areas where freshwater supplies are limited, the economics of this process can be critical. However, crude oil desalting techniques in the field have improved with the introduction of the electrostatic coalescing process (Figure 7.2). Even when adequate supplies of freshwater are available for desalting operations, preparation of the water for dilution purposes may still be expensive.

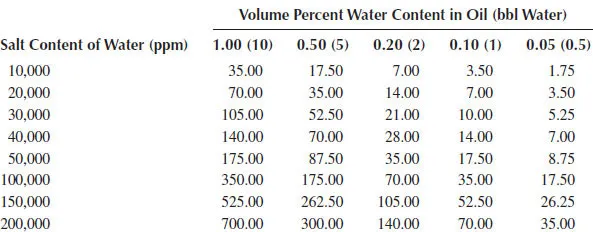

Requirements for dilution water ratios based on water salinity calculations (Table 7.1; Figure 7.3) can be calculated as a material balance and by combining the arithmetic mean of material balance and water injection and dispersion for contact efficiency, very low dilution water use rates can be achieved. This can be highly significant in an area where production rates of 100,000 bbl/day are common and freshwater supply is limited.

FIGURE 7.2 General methods for desalting crude oil.

TABLE 7.1

Pounds of Salt per 1000 bbl of Crude Oil

Pounds of Salt per 1000 bbl of Crude Oil

Desalter units generally will produce a dehydrated stream containing like amounts of bottom sediment and water (BS&W) from each stage. Therefore, bottom sediment and water can be considered as pass through volume, and the dilution water added is the amount of water to be recycled. The recycle pump, however, generally is oversized to compensate for difficult emulsion conditions and upsets in the system. Dilution water calculations for a two-stage system using recycle are slightly more complicated than for a single-stage process (Table 7.2; Figure 7.4) or a two-stage process without recycle (Table 7.3; Figure 7.5).

The common approach to desalting crude oil involves use of the two-stage desalting system (Figure 7.5) in which dilution water is injected between stages after the stream water content has been reduced to a very low level by the first stage. Further reduction is achieved by adding the second-stage recycle pump. The second-stage water is much lower in sodium chloride (NaCl) than the produced stream inlet water due to addition of dilution water. By recycling this water to the first stage, both salt reduction and dehydration are achieved in the first stage. The water volume to be recycled is assumed to be the same as dilution water injection volume.

A very low bottom sediment and water content at the first-stage desalter exit requires a high percentage of dilution water to properly contact dispersed, produced water droplets ...