3D Printing Basics for Entertainment Design

Anne E. McMills

- 416 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

3D Printing Basics for Entertainment Design

Anne E. McMills

À propos de ce livre

Affordable 3D printers are rapidly becoming everyday additions to the desktops and worktables of entertainment design practitioners – whether working in theatre, theme parks, television and film, museum design, window displays, animatronics, or… you name it! We are beginning to ask important questions about these emerging practices:

· How can we use 3D fabrication to make the design and production process more efficient?

· How can it be used to create useful and creative items?

· Can it save us from digging endlessly through thrift store shelves or from yet another late-night build?

· And when budgets are tight, will it save us money?

This quick start guide will help you navigate the alphabet soup that is 3D printing and begin to answer these questions for yourself. It outlines the basics of the technology, and its many uses in entertainment design. With straightforward and easy-to-follow information, you will learn ways to acquire printable 3D models, basic methods of creating your own, and tips along the way to produce successful prints.

Over 70 professionals contributed images, guidance, and never-before-seen case studies filled with insider secrets to this book, including tutorials by designer and pioneer, Owen M. Collins.

Foire aux questions

Informations

Part I

The Basics

So, What Exactly is 3D Printing?

- Rapid Prototyping (RP)

- Rapid Manufacture (RM)

- Rapid Tooling (RT)

- Additive Manufacturing (AM)

- Additive Layer Manufacture (ALM)

- 3D or Desktop Fabbing

- Direct Digital Fabrication

- Personal Manufacturing

- Desktop Manufacturing

- Digital Manufacturing

Chapter 1

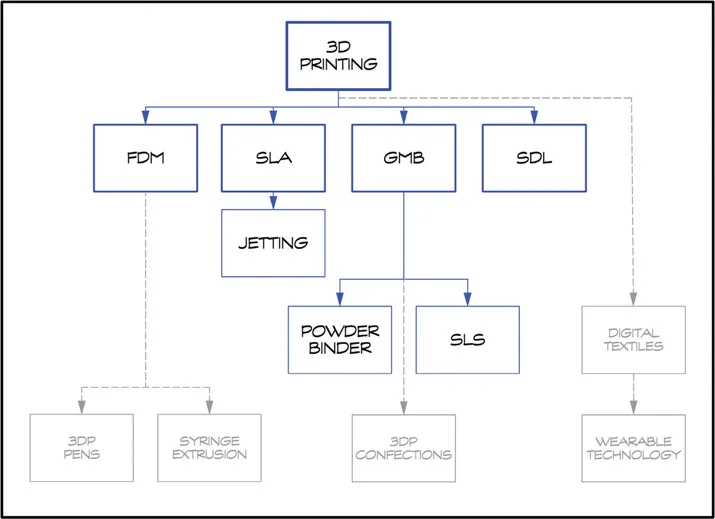

Methods of 3D Printing

Printing Techniques

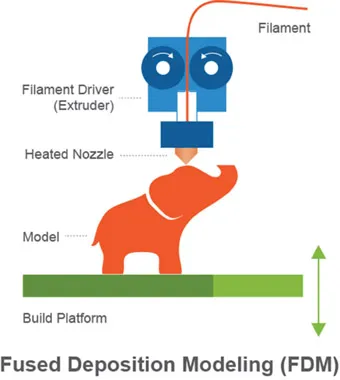

Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Molten Polymer Deposition (MPD)

- Thermoplastic Extrusion

- Fused Filament Method (FFM)

- Plastic Jet Printing (PJP)

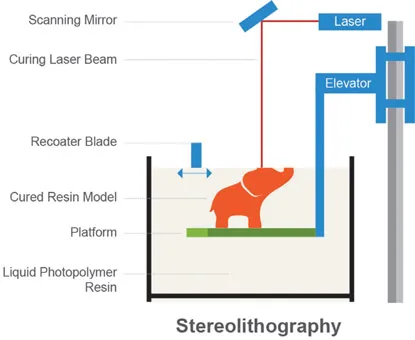

Stereolithography (SLA)

- Optical Fabrication

- Photo-Solidification

- Solid Free-Form Fabrication

- Solid Imaging