![]()

1

A Scientific Thinking Mechanism for Improvement

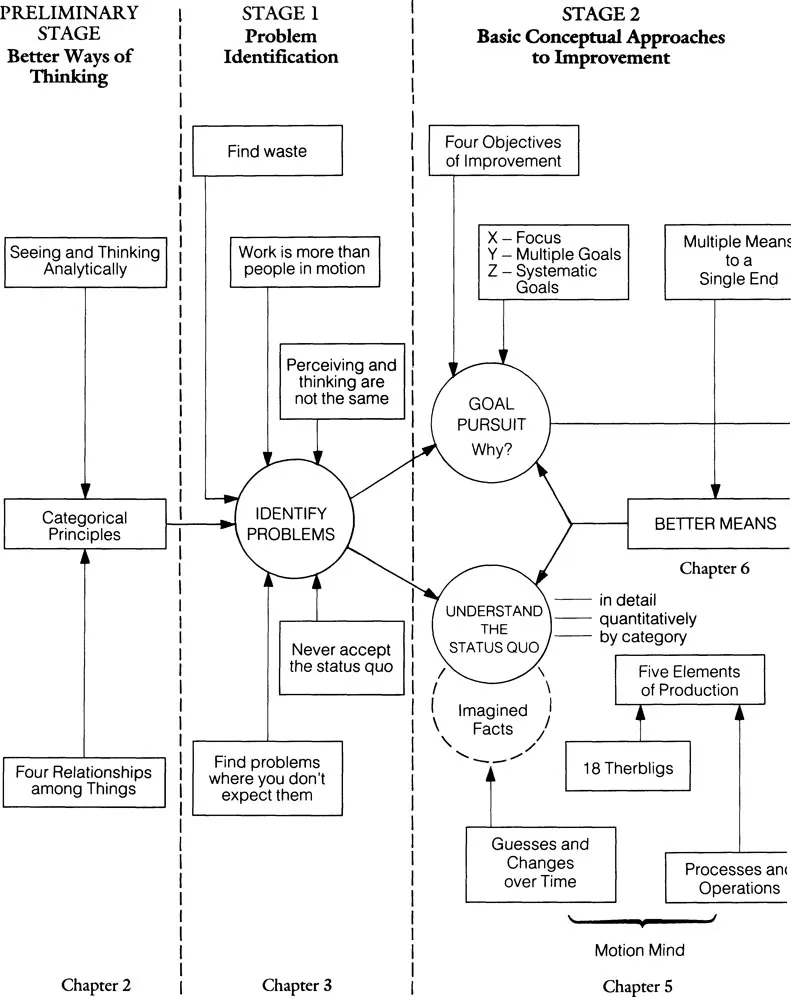

Many improvement philosophies and techniques advocated in the past address only parts or aspects of a problem and have failed to be comprehensive and systematic. I propose a scientific approach to thinking through problems (STM) that combines these various philosophies and techniques in a systematic way. A schematic outline of this STM is given in Figure 1 and the suggestions I make throughout the book follow the categories shown.

THE RELATIONSHIP BETWEEN STM AND TECHNIQUES FOR RATIONALIZING PRODUCTION

Various techniques have been proposed to make production more rational. These methods are classified below on the basis of their characteristics.

Analytic and Quantitative Methods for Assessing the Status Quo

The following methods allow us to get a grip on the status quo — to improve the conditions we find, we need to think about them scientifically and systematically using STM.

1. Motion analysis: analysis of motions themselves

2. Time analysis: temporal analysis

3. Work analysis: analysis of work done by humans or machines

4. Process analysis: analysis of the course of changes undergone by products

5. Work factor (WF), methods time management (MTM) analysis: operation time analysis with the addition of leveling (evaluation of human work averages)

FIGURE 1. Scientific Thinking Mechanism

6. Work sampling: an analytical method that borrows sampling techniques from statistics to make measurement easier

7. Control charts: a method that makes it easy to grasp the current state of quality

8. Histograms: a method of grasping the current state of quality quantitatively

Methods That Provide Clear Objectives and Motivate People

Rather than merely telling people to work better, it is much more productive to set out clear objectives and to provide motivation.

Management by objectives (MBO). No matter how effective it may be to set clear objectives and then strive to achieve them, bursts of effort alone won’t do the trick; in the final analysis, methods must be improved.

Zero defects (ZD). A ZD campaign aimed at cutting defects to zero is a kind of management by objectives. To attain those objectives, however, requires an approach to improvement that goes beyond simple awareness of the problem and conventional modes of thinking.

Work design. In industrial engineering, improvements are based on the status quo. Work-design techniques, on the other hand, advocate seeking absolute measures — starting from zero in terms of materials, labor, and all other cost, and permitting only the minimum required costs. This enables us to pursue higher-level goals than are possible with improvement methods that start with the current situation as a base. In this respect, work-design techniques are undoubtedly effective tools. To identify the absolute minimum means needed, however, requires a thinking mechanism that is rigorous and systematic.

Methods for Setting Standards Rationally

It is natural to want to set standards rationally. It seems to me, however, that theoretical pursuits tend to become goals in themselves, and people forget that those pursuits are merely a means for rationalizing production. In other words, management can end up subordinated to the pursuit of mathematical methods.

Statistical quality control (SQC or SPC). Looking over published works on quality control (QC), I cannot help thinking that too many pages are devoted to mathematical and statistical processing methods for setting standards. Isn’t this the prime reason most supervisors on the shop floor consider QC difficult to understand? Quality control should never be confined to scholarly theoretical studies; it has to be comprehensible to ordinary managers and shop-floor supervisors.

No doubt it is a valid perception that much of Japan’s success in achieving high levels of quality is the result of workers’ improvement activities, such as QC circles. Now, however, we must recognize the importance of total quality control (TQC) involving every individual and division within the enterprise.

We are also discovering that most defects occur not because of improperly set standards, but as the result of errors in control and execution. Surely, the fact that source inspection and the poka-yoke system permit continuous zero-defect production in so many plants bears eloquent testimony to this assertion. There is still considerable room, however, for further improvement by applying STM.

Quality management (QM). QM has achieved considerable popularity recently. Like SQC, it elevates the importance of setting standards — in itself a perfectly justifiable position. Yet if we want to make the production shop more efficient, the question of which sort of evaluation is appropriate is a bit beside the point. This method is undoubtedly useful for firms, such as those in the chemical industry, which are significantly influenced by whether standards are set correctly. I think it is important, however, to stay alert to the danger of allowing scholarly interests to dictate methods that are of little use in actually improving shop efficiency.

Value engineering (VE) and value analysis (VA). Lawrence D. Miles’s concepts of value engineering and value analysis define value as function in relation to cost and call for the thorough study of both function and cost issues. The scientific thinking mechanism for improvement — as an approach that analyzes the status quo, pursues ends, and recognizes multiple means to a single end — can also be effectively applied to the goal of achieving value.

It is also necessary, however, to use a scientific approach in applying categorical principles and modes of problem awareness — especially locking in on problems, brainstorming, judging, and making proposals — and in implementing suggested improvements in the workplace.

The economic lot. The economic lot theory makes the rational claim that the burden of setup times is reduced as processing-lot size increases but that, since on the other hand this causes stocks to increase, a balance must be struck between the two factors. This calculation, however, has been rendered effectively worthless by the concept of SMED (single-minute exchange of die), which can reduce setup times from four hours to three minutes. Implementing SMED effectively also involves the application of a scientific thinking mechanism.

Materials requirements planning (MRP). Many plants are adopting some form of MRP to set optimum order points and order amounts for parts and materials. Computers are being used to make these determinations. On the other hand, SMED makes extremely small installment deliveries possible; and one-piece flows can reduce lead time from days down to hours.

What effect, then, does MRP have when production methods themselves can be improved? The scientific thinking mechanism for improvement can be used to implement SMED and dramatically shorten lead times.

Rationalization of Means

The term rationalization sometimes refers simply to making means rational rather than to making goals or ends rational. For example, human work becomes easier and productivity surges when manual functions are augmented by tools, and again when these tools are mechanized and automated. Human labor has been made even easier and production further increased by developments that include:

• machining centers that replace tools automatically

• numerical control (NC) machines that automate dimension settings and carry out compound operations automatically

• robots that automate manual operations

In many of these cases, however, only means have been rationalized while rationalization of ends — the thorough improvement of operating methods — has been neglected. This point requires extensive reconsideration but, in either event, improvement is more effectively pursued by invoking the scientific thinking mechanism.

Computers. This is the age of almighty computers, performing complex calculations at overwhelming speeds with immense memories.

At a certain American firm, I heard the boast that even with extensive stocks, a three-dimensional automatic warehouse made it possible to retrieve a needed part within three minutes. When my hosts inserted a card in a computer, the indicated part did in fact arrive within three minutes. Yet when I compared this company with one at which adoption of a stockless production system had eliminated the need for warehouses, I wondered which company had more truly rationalized its operations.

Preventive maintenance (PM). When we follow the principles of preventive maintenance, machines are maintained so thoroughly that no breakdowns occur. Using the scientific thinking mechanism in applying these principles can be extremely effective. At the same time, we must not forget to consider the rationalization of ends — to ask how machines should be used to rationalize production.

* * * * * * *

These are some of the techniques used to rationalize production that can be enhanced through the application of the scientific thinking mechanism for improvement (STM). I want to stress the continuing fundamental need, in aiming for rationalization, for a systematic, scientific approach to improvement. The chapters that follow contain specific suggestions that illustrate different aspects of that improvement process.

![]()

2

Preliminary Stage: Basic Ways of Thinking

CATEGORICAL PRINCIPLES

Categorical principles guide our thinking and help us classify ideas and observations.

There Are Many Categorical Principles in the World

There are many categorical principles, and consequently many different classifications are possible. For example, humans may be classified in a number of ways:

men versus women: sex

those who wear glasses versus those who don’t: visual acuity

adults versus children: age

sick people versus healthy peo...