eBook - ePub

Advanced Vehicle Technology

Heinz Heisler

This is a test

Partager le livre

- 656 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

eBook - ePub

Advanced Vehicle Technology

Heinz Heisler

Détails du livre

Aperçu du livre

Table des matières

Citations

À propos de ce livre

This eagerly awaited second edition of Heinz Heisler's Advanced Vehicle Technology is a comprehensive and thorough description of vehice bodies and components.

The second edition has been rigorously updated to provide additional material on subjects such as antilock braking, vehicle aerodynamics, tire tread design advances, electronically controlled anti-vibration engine mountings and transport refrigeration. Around 100 new diagrams have been included to complement the text.

Advanced Vehicle Technology 2nd edition's depth of coverage, detailed illustrations and fluent and precise style are the outstanding features in this high quality student text.

- More quality artwork has been added to enhance and add value to the explanation given in the text

- 16 key topics have been updated to bring this 2nd edition in line with current technology

- Fully international in scope, reflecting the nature of contemporary vehicle engineering

Foire aux questions

Comment puis-je résilier mon abonnement ?

Il vous suffit de vous rendre dans la section compte dans paramètres et de cliquer sur « Résilier l’abonnement ». C’est aussi simple que cela ! Une fois que vous aurez résilié votre abonnement, il restera actif pour le reste de la période pour laquelle vous avez payé. Découvrez-en plus ici.

Puis-je / comment puis-je télécharger des livres ?

Pour le moment, tous nos livres en format ePub adaptés aux mobiles peuvent être téléchargés via l’application. La plupart de nos PDF sont également disponibles en téléchargement et les autres seront téléchargeables très prochainement. Découvrez-en plus ici.

Quelle est la différence entre les formules tarifaires ?

Les deux abonnements vous donnent un accès complet à la bibliothèque et à toutes les fonctionnalités de Perlego. Les seules différences sont les tarifs ainsi que la période d’abonnement : avec l’abonnement annuel, vous économiserez environ 30 % par rapport à 12 mois d’abonnement mensuel.

Qu’est-ce que Perlego ?

Nous sommes un service d’abonnement à des ouvrages universitaires en ligne, où vous pouvez accéder à toute une bibliothèque pour un prix inférieur à celui d’un seul livre par mois. Avec plus d’un million de livres sur plus de 1 000 sujets, nous avons ce qu’il vous faut ! Découvrez-en plus ici.

Prenez-vous en charge la synthèse vocale ?

Recherchez le symbole Écouter sur votre prochain livre pour voir si vous pouvez l’écouter. L’outil Écouter lit le texte à haute voix pour vous, en surlignant le passage qui est en cours de lecture. Vous pouvez le mettre sur pause, l’accélérer ou le ralentir. Découvrez-en plus ici.

Est-ce que Advanced Vehicle Technology est un PDF/ePUB en ligne ?

Oui, vous pouvez accéder à Advanced Vehicle Technology par Heinz Heisler en format PDF et/ou ePUB ainsi qu’à d’autres livres populaires dans Tecnologia e ingegneria et Ingegneria meccanica. Nous disposons de plus d’un million d’ouvrages à découvrir dans notre catalogue.

Informations

1

Vehicle Structure

1.1 Integral body construction

The integral or unitary body structure of a car can be considered to be made in the form of three box compartments; the middle and largest compartment stretching between the front and rear road wheel axles provides the passenger space, the extended front box built over and ahead of the front road wheels enclosing the engine and transmission units and the rear box behind the back axle providing boot space for luggage.

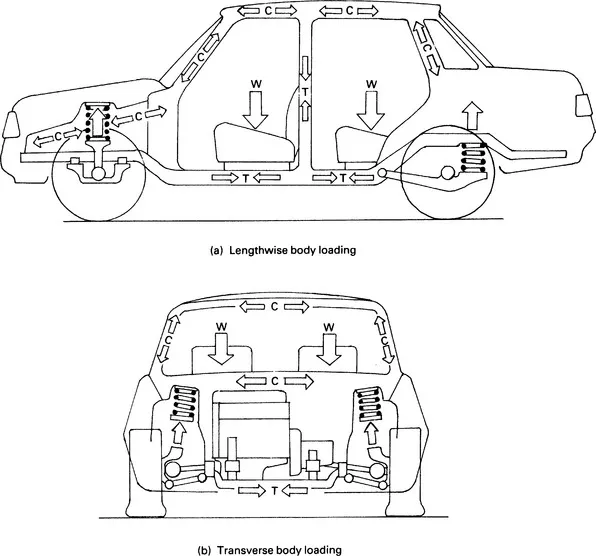

These box compartments are constructed in the form of a framework of ties (tensile) and struts (compressive), pieces (Fig. 1.1(a & b)) made from rolled sheet steel pressed into various shapes such as rectangular, triangular, trapezium, top-hat or a combination of these to form closed box thin gauge sections. These sections are designed to resist direct tensile and compressive or bending and torsional loads, depending upon the positioning of the members within the structure.

Fig. 1.1 (a and b) Structural tensile and compressive loading of car body

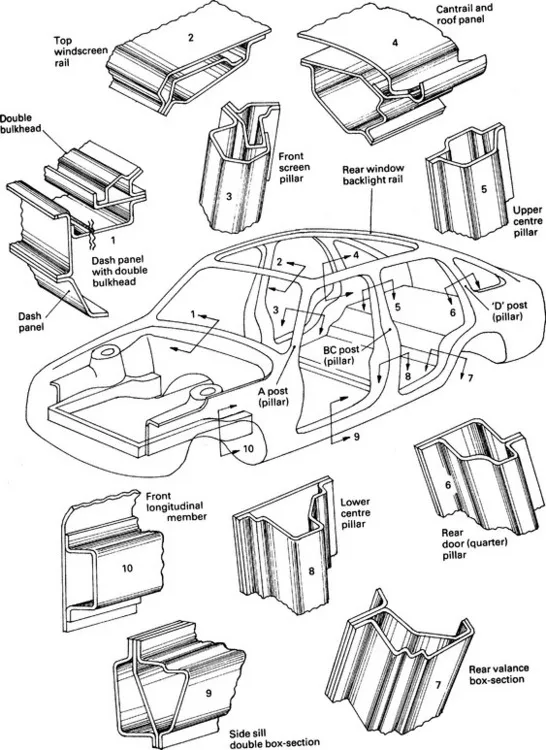

1.1.1 Description and function of body components (Fig. 1.2)

The major individual components comprising the body shell will now be described separately under the following subheadings:

1. Window and door pillars

2. Windscreen and rear window rails

3. Cantrails

4. Roof structure

5. Upper quarter panel or window

6. Floor seat and boot pans

7. Central tunnel

8. Sills

9. Bulkhead

10. Scuttle

11. Front longitudinals

12. Front valance

13. Rear valance

14. Toe board

15. Heel board

Window and door pillars (Fig. 1.2(3, 5, 6, and 8)) Windowscreen and door pillars are identified by a letter coding; the front windscreen to door pillars are referred to as A post, the centre side door pillars as BC post and the rear door to quarter panel as D post. These are illustrated in Fig. 1.2.

Fig. 1.2 Load bearing body box-section members

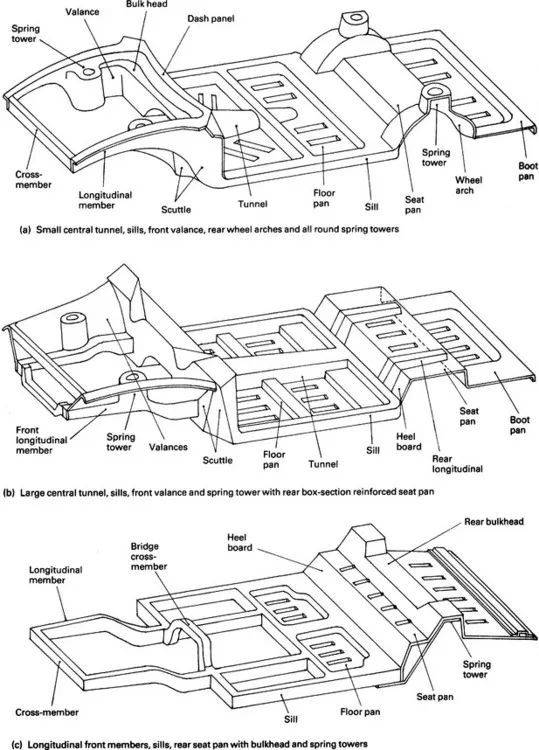

Fig. 1.3(a–c) Platform chassis

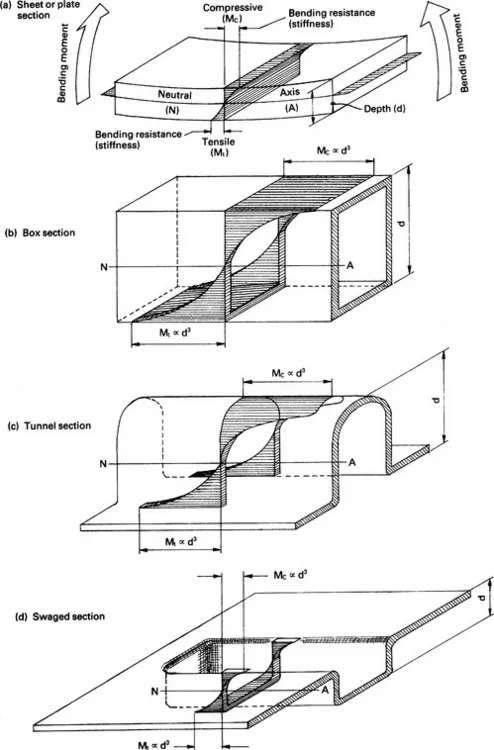

Fig. 1.5 Bending resistance for various sheet sections

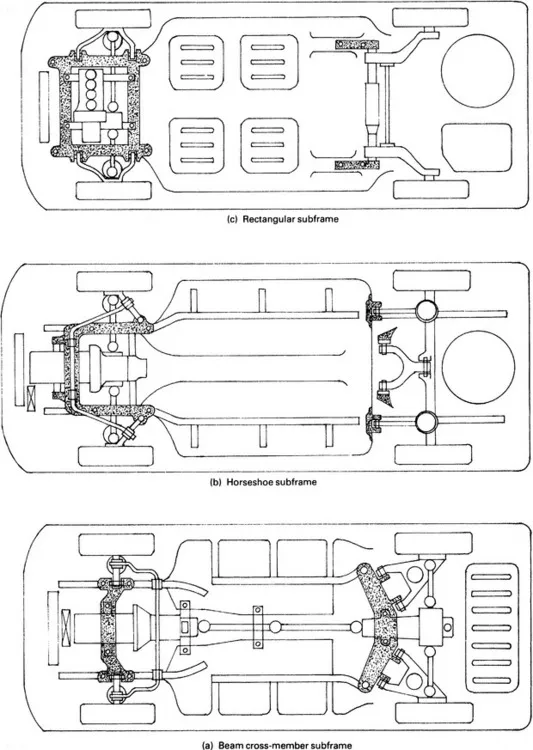

Fig. 1.6 (a–c) Body subframe and underfloor structure

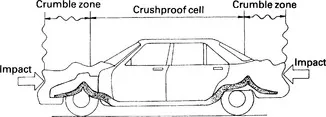

Fig. 1.8 Collision body safety

These pillars form the part of the body structure which supports the roof. The short form A pillar and rear D pillar enclose the windscreen and quarter windows and provide the glazing side channels, whilst the centre BC pillar extends the full height of the passenger compartment from roof to floor and supports the rear side door hinges. The front and rear pillars act as struts (compressive members) which transfer a proportion of the bending effect, due to underbody sag of the wheelbase, to each end of the cantrails which thereby become reactive struts, opposing horizontal bending of the passenger compartment at floor level. The central BC pillar however acts as ties (tensile members), transferring some degree of support from the mid-span of the cantrails to the floor structure.

Windscreen and rear window rails (Fig. 1.2(2)) These box-section rails span the front window pillars and rear pillars or quarter panels depending upon design, so that they contribute to the resistance opposing transverse sag between the wheel track by acting as compressive members. The other function is to support the front and rear ends of the roof panel. The undersides of the rails also include the glazing channels.

Cantrails (Fig. 1.2(4)) Cantrails are the horizontal members which interconnect the top ends of the vertical A and BC or BC and D door pillars (posts). These rails form the side members which make up the rectangular roof framework and as such are subjected to compressive loads. Therefore, they are formed in various box-sections which offer the greatest compressive resistance with the minimum of weight and blend in with the roofing. A drip rail (Fig. 1.2(4)) is positioned in between the overlapping roof panel and the cantrails, the joins being secured by spot welds.

Roof structure (Fig. 1.2) The roof is constructed basically from four channel sections which form the outer rim of the slightly dished roof panel. The rectangular outer roof frame acts as the compressive load bearing members. Torsional rigidity to resist twist is maximized by welding the four corners of the channel-sections together. The slight curvature of the roof panel stiffens it, thus preventing winkling and the collapse of the unsupported centre region of the roof panel. With large cars, additional cross-rail members may be used to provide more roof support and to prevent the roof crushing in should the car roll over.

Upper quarter panel or window (Fig. 1.2(6)) This is the vertical side panel or window which occupies the space between the rear side door and the rear window. Originally the quarter panel formed an important part of the roof support, but improved pillar design and the desire to maximize visibility has either replaced them with quarter windows or reduced their width, and in some car models they have been completely eliminated.

Floor seat and boot pans (Fig. 1.3) These constitute the pressed rolled steel sheeting shape to enclose the bottom of both the passenger and luggage compartments. The horizontal spread-out pressing between the bulkhead and the heel board is called the floor pan, whilst the raised platform over the rear suspension and wheel arches is known as the seat or arch pan. This in turn joins onto a lower steel pressing which supports luggage and is referred to as the boot pan.

To increase the local stiffness of these platform panels or pans and their resistance to transmitted vibrations such as drumming and droning, many narrow channels are swaged (pressed) into the steel sheet, because a sectional end-view would show a semi-corrugated profile (or ribs). These channels provide rows of shallow walls which are both bent and stretched perpendicular to the original flat sheet. In turn they are spaced and held together by the semicircular drawn out channel bottoms. Provided these swages are designed to lay the correct way and are not too long, and the metal is not excessively stretched, they will raise the rigidity o...