Architectured Materials: An Alternative to Microstructure Control for Structural Materials Design? A Possible Playground for Bio-inspiration?

YVES J. M. BRÉCHET

The classical dichotomy between structure and materials to meet design requirements has led to separate routes, microstructure optimization and shape optimization. The increasing demand on a combination of properties in materials, and the required multi-functionality in present-day design can often no longer be met with ‘classical materials’. Architectured materials are a combination of material(s), shape and topology, at length scales comparable to the scale of the components. These materials offer an alternative strategy for ‘materials by design’. The occurrence of several length scales and the central role of geometry in this new class of materials, as well as the hierarchical structure often seen in biomaterials, suggest that bio-inspiration could be an interesting approach to the development of this innovative strategy.

1.1 Introduction: Materials, Structure and Between

From the engineering viewpoint, materials are matter with a function. In order to fulfil this function, the properties of materials are only one of the variables; the shape and the scale can also contribute to give to a component the required response to an external stimulus, which is the so-called ‘function’. If a buoyancy device is required, a material such as cork, whose density is lower than that of water, might be sought, but a steel hollow sphere might also suffice. If a conductor that can carry electricity with little joule loss and yet will remain flexible is required, the natural solution will be to look for materials with low resistivity (such as copper) and to play on the scale (fragmenting the rod into wires) to obtain the required flexibility. In these very simple examples, it can be clearly seen that the function is related not to the property, but to a combination of materials, shape and scale. As a consequence, processes play a central role in proceeding from the ‘matter’ status to the ‘materials status’: processes allow us to obtain the shape, to control the scale and, in some materials such as metallic alloys, to obtain some properties.

Traditionally, the field of knowledge was clearly partitioned between different scientists. Optimizing properties via the chemical building block was devoted to solid state chemistry or organic chemistry, microstructure was the goal of metallurgists, macroscopic structures would be optimized by mechanical engineers and electrical engineers, and process engineers would tell how to shape a given material into a given shape. This division was based on a sort of ‘scale’ separation: the features in the microstructure controlling, for example, the yield stress were on length scales much smaller than the scales of the component, e.g. the sheet for an airplane wing. If a change to the stiffness of the wing was required, the composition (developing Al–Li alloys) or the shape (developing a whole anthology of stiffeners), or both could equally well be changed.

This ‘gentlemen’s agreement’ between ‘composition/microstructure/structure’ was first challenged in engineering materials when the scale of the microstructure became commensurate with the scale of the components. This occurred at both ends of the length scale. At the macroscopic level, the use of fibre-reinforced polymer composites, with the associations of different plies with different orientations could lead to shape-dependent properties. At the microscopic level, the scaling down in microelectronics led to dimensions when electron scattering by the interface of the copper ‘vias’ with the dielectric and the diffusion barriers become very important: resistivity is no longer a property of the materials, but of materials at a given scale.

Now a second challenge appears with the understanding of ‘natural materials’: since they are, hierarchical, as many examples show it in this book, the decoupling between ‘structure, microstructure and composition’ becomes less and less relevant.

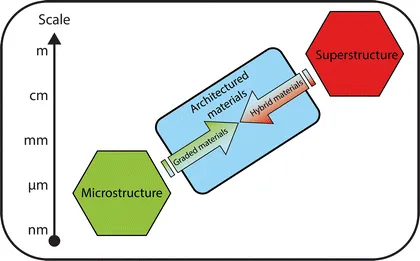

From an engineering perspective, the need to develop materials with conflicting properties (such as strength and toughness, or conductivity and flexibility) has led, first in a empirical way, and now in an emerging systematic manner, to the concept of ‘architectured materials’, i.e. associations of materials/shape/scales in order to fulfil multi-objectives/multi-constraints design requirements.1–3 The key concept is that the variability of properties (i.e. of composition and/or microstructures) occurs on length scales comparable to the dimensions of the component. If we go back to the traditional microstructure/structure dichotomy, that means developing gradients of microstructures (graded materials) and distribution of matter (hybrid materials) and all the possible variations and combinations of these two strategies. The positioning of this strategy is shown in Figure 1.1.

Figure 1.1 The different length scales and the position of architectured materials.

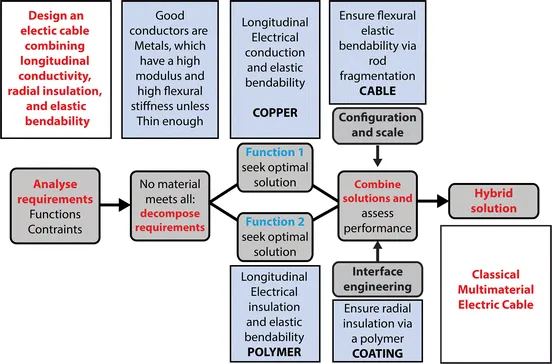

To illustrate the overall strategy by using a simple example, let’s consider the necessity to develop electric cables that should be flexible. Obviously, there is no single material which can be conductive enough in the longitudinal direction, insulating enough in the radial direction, and sufficiently bendable. Electrical conductivity comes with free electrons which are associated with a strong interatomic bonding which implies a high elastic modulus. Low electrical resistance imposes high conductivity and precludes the small cross section that would be required by a good flexibility. The reasoning to meet these conflicting requirements is shown schematically in Figure 1.2.

Figure 1.2 Schematic of the design reasoning leading to an ‘engineering architecture material’ and its application to the design of an electric cable.

The trick is then to decouple the function (longitudinal conduction and radial insulation), to select the conducting materials (metals) and the insulating materials (polymer or ceramic) and to ensure flexural elastic bendability for the conductor by fragmenting the rod into filaments, for the coating by selecting a polymer rather than a ceramic. If, in addition, high strength is required (for instance in the design of wirings for high magnetic fields for which a high magnetic pressure has to be contained), development can be carried out on a different scale – the microstructure of the conductor – to bypass the intrinsic contradiction between high conductivity (which requires high purity and few defects in the metal) and the high strength (which requires a large density of obstacles to dislocation motion). Systems such as poly-nano-twinned copper or hyper-deformed copper–niobium composites provide such a compromise.4,5 An alternative solution for less critical requirements on strength (such as an electric cable which would have to sustain its own weight plus some external load (snow for instance) would lead to a mixed cable of steel/aluminium. Table 1.1 gives a few examples among many of classical conflicting requirements and their solution, and of specific engineering challenges and a possible architecture solution.

Table 1.1 Examples of multi-objective engineering problems that can be solved by using architectured materials.

| Conflicting requirements | Architectured materials |

| Combining tensile strength and flexural bendability | Cables |

| Plate combining lightness, flexural stiffness in one direction, and bendability in the other | Corrugated plates |

| Combining strength and damage tolerance with respect to surface defects | Soft layer on a hard substrate, such as a surface decarburised martensitic steel |

| Combining strength and corrosion resistance in a light alloy | Aluminium plates cladded with pure aluminium |

| Engineering objective | Architectured solutions |

| • Combining thermal conductivity and heat capacity for energy management | • Metallic wools or honeycomb filled with phase transformation materials |

| • Combining high thermal conductivity and low thermal expansion coefficient | • Mixture of metals and ceramics, copper/diamond, etc. |

| • Combining strength, thermal insulation and small gas permeability | • Multilayer polymer metal coatings |

| • Combining strength and toughness | • Phase transformation toughening ceramics, ceramic–polymer multilayers |

| • Combining deformability and magnetic strength, and possibly magnetostriction with large displacement | • Polymers reinforced with magnetic particles |

| • Thermally driven actuator | • Bimetallic strip |

| • Optical transparency, strength and safety in fracture | • Glass plates with polymer films |

| • Heat exchangers at minimum weight and resistant to oxidation | • Vapour deposited copper of a polymeric foam followed by cracking and surface treatment |

| • High strength cutting tool for fast machining | • Combination in a saw of a high conductivity copper core with a cermet blade |

| • Tiles for ablation and thermal protection for aerospace reservoirs | • Graded foams in a sandwich structure |

| • Diverter for fusion reactors extracting heat and resisting to plasma ablation | • Copper–tungsten multi-layers |

| • Shock protecting helmet with comfort | • Sandwich structure with a graded polyurethane foam |