Analysis and Performance of Fiber Composites

Bhagwan D. Agarwal, Lawrence J. Broutman, K. Chandrashekhara

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

Analysis and Performance of Fiber Composites

Bhagwan D. Agarwal, Lawrence J. Broutman, K. Chandrashekhara

À propos de ce livre

Updated and expanded coverage of the latest trends and developments in fiber composite materials, processes, and applications

Analysis and Performance of Fiber Composites, Fourth Edition features updated and expanded coverage of all technical aspects of fiber composites, including the latest trends and developments in materials, manufacturing processes, and materials applications, as well as the latest experimental characterization methods.

Fiber reinforced composite materials have become a fundamental part of modern product manufacturing. Routinely used in such high-tech fields as electronics, automobiles, aircraft, and space vehicles, they are also essential to everyday staples of modern life, such as containers, piping, and appliances. Little wonder, when one considers their ease of fabrication, outstanding mechanical properties, design versatility, light weight, corrosion and impact resistance, and excellent fatigue strength. This Fourth Edition of the classic referencethe standard text for composite materials courses, worldwideoffers an unrivalled review of such an important class of engineering materials.

Still the most comprehensive, up-to-date treatment of the mechanics, materials, performance, analysis, fabrication, and characterization of fiber composite materials available, Analysis and Performance of Fiber Composites, Fourth Edition features:

- Expanded coverage of materials and manufacturing, with additional information on materials, processes, and material applications

- Updated and expanded information on experimental characterization methodsincluding many industry specific tests

- Discussions of damage identification techniques using nondestructive evaluation (NDE)

- Coverage of the influence of moisture on performance of polymer matrix composites, stress corrosion of glass fibers and glass reinforced plastics, and damage due to low-velocity impact

- New end-of-chapter problems and exercises with solutions found on an accompanying website

- Computer analysis of laminates

No other reference provides such exhaustive coverage of fiber composites with such clarity and depth. Analysis and Performance of Fiber Composites, Fourth Edition is, without a doubt, an indispensable resource for practicing engineers, as well as students of mechanics, mechanical engineering, and aerospace engineering.

Visit the Companion Website at: https://www.wiley.com/WileyCDA/Section/id-830336.html

Foire aux questions

Informations

1

INTRODUCTION

1.1 DEFINITION

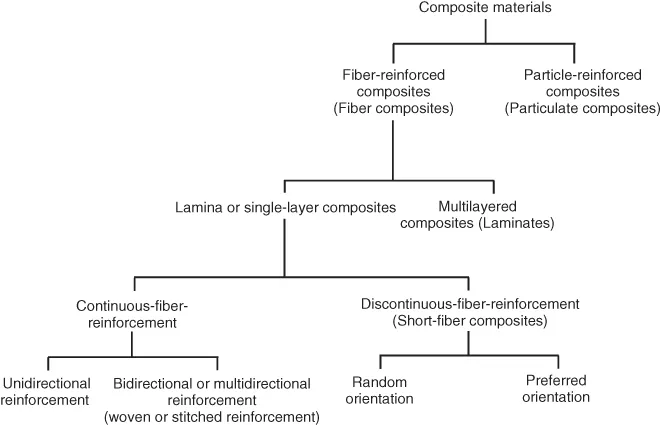

1.2 CLASSIFICATION