![]()

CHAPTER 1

Planning Experiments

1.1 INTRODUCTION

The principles governing the engineering aspects of food processing are the same as those applied in any engineering field in that engineers are educated to analyze, synthesize, design, and operate complex systems that manipulate mass, energy, and information to transform materials and energy into useful forms, which, in this case, are food products or food ingredients. This book is designed to give food engineering and/or food science students an understanding of the engineering principles and hands-on experiences involved in the processing of food products. With a clear understanding of the engineering basic principles of food processing, it is possible to develop new food processes and modify existing ones. Because an essential component of any laboratory exercise is to receive proper laboratory orientation, follow safety guidelines, and prepare laboratory reports, this chapter deals with fundamental engineering aspects related to specific laboratory exercises, how to get ready for an experiment, and how to report it.

1.2 MASS BALANCE

The law of conservation of mass states that mass cannot be created nor destroyed, so a mass balance in any process can be written as follows:

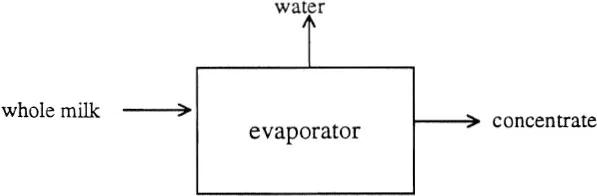

In a continuous process at steady state, the accumulation is zero. Therefore, a simple rule that “what goes in must come out” holds. For example, in the concentration process of milk, whole milk is fed into an evaporator. Under the law of conservation of mass, the total number of pounds of material (whole milk) entering the evaporator per unit time must equal the total number of pounds of concentrated milk and evaporated moisture that leave the evaporator. When solving the mass balance, four key steps must be followed:

(1) Select a system and draw a diagram representing the process (including all pertinent information on stream rate and compositions).

(2) Select an appropriate basis for calculation.

(3) Write the mass balance relationships for the various constituents in terms of the known and unknown quantities.

(4) Solve the resulting algebraic equations for the unknown quantities.

1.2.1 Example

A milk concentrate is to be made by evaporating water from whole milk. The whole milk contains 13% total solids (TS), and the concentrate should contain 49% TS. Calculate the amount of product and the water that needs to be evaporated.

1.2.1.1 SOLUTION

• Step 1: Select the evaporator to be a target system, and draw a diagram representing the process as follows:

• Step 2: Select a basis for the calculation of 100 kg of incoming whole milk.

• Step 3: Write up the equations for the mass balance:

(1) The balance for the total material:

| (1.1) |

(2) The balance of total solids (TS):

| (1.2) |

• Step 4: Solve the equations. Note that Equation (1.2) has only one unknown and should therefore be solved first. The result is:

Substituting the C value into Equation (1.1), we get:

• Step 5: Appropriate answer: From every 100 kg of whole milk, we can manufacture 26.5 kg of the concentrated milk, and thus 73.5 kg of water must be evaporated.

1.3 ENERGY BALAN...