1.1 ABRASIVE PROCESSES

Abrasive machining processes are manufacturing techniques which employ very hard granular particles in machining, abrading, or polishing to modify the shape and surface texture of manufactured parts.

A wide range of such processes is mostly used to produce high quality parts to high accuracy and to close tolerances. Examples range from very large parts such as machine slideways to small parts such as contact lenses, needles, electronic components, silicon wafers, and ball bearings.

While accuracy and surface texture requirements are common reasons for selecting abrasive processes, there is another common reason. Abrasive processes are the natural choice for machining and finishing hard materials and hardened surfaces.

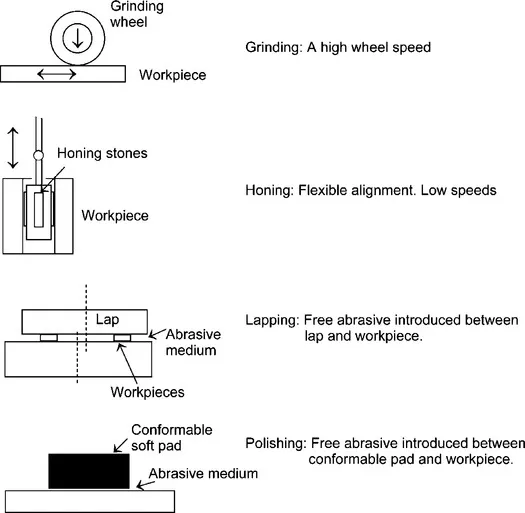

Most abrasive processes may be categorized into one of four groups: (i) grinding, (ii) honing, (iii) lapping, (iv) polishing.

This is not a completely inclusive list, but the four groups cover a wide range of processes and are a sufficient representation for a study of fundamental characteristics of such processes. These four groups are illustrated in Fig. 1.1. Grinding and honing are processes which employ bonded or fixed abrasives within the abrasive tool, whereas lapping and polishing employ free abrasive particles, often suspended in a liquid or wax medium.

Figure 1.1 Basic principles of grinding, honing, lapping, and polishing.

1.1.1 Grinding

In grinding, the abrasive tool is a grinding wheel which moves at a high surface speed compared to other machining processes such as milling and turning. Surface speeds are typically in the range of 20 m/s (4,000 ft/min) to 45 m/s (9,000 ft/min) in conventional grinding. In high-speed grinding, the wheel moves at speeds up to 140 m/s with wheels especially designed to withstand the high bursting stresses. Speeds greatly in excess of 140 m/s may be employed, but the proportion of applications at such speeds is small due to the expense and sophistication of the machines and techniques involved.

Although grinding can take place without lubrication, wet grinding is preferred wherever possible due to the reduced frictional losses and improved quality of the surfaces produced. Commonly used lubricants include oil in water emulsions and neat oils.

1.1.2 Honing

In honing, the abrasive particles, or grains as they are commonly known, are fixed in a bonded tool as in grinding. The honing process is mainly used to achieve a finished surface in the bore of a cylinder. The honing stones are pressurized radially outwards against the bore. Honing is different than grinding in two ways.

First, in honing, the abrasive tool moves at a low speed relative to the workpiece. Typically, the surface speed is 0.2 m/s to 2m/s. Combined rotation and oscillation movements of the tool are designed to average out the removal of material over the surface of the workpiece and produce a characteristic “cross-hatch” pattern favored for oil retention in engine cylinder bores.

Another difference between honing and grinding is that a honing tool is flexibly aligned to the surface of the workpiece. This means that eccentricity of the bore relative to an outside diameter cannot be corrected.

1.1.3 Lapping

In lapping, free abrasive is introduced between a lap, which may be a cast iron plate, and the workpiece surface. The free abrasive is usually suspended in a liquid medium, such as oil, providing lubrication and helping to transport the abrasive. The lap and the abrasive are both subject to wear. To maintain the required geometry of the lap and of the workpiece surface, it is necessary to pay careful attention to the nature of the motions involved to average out the wear across the surface of the lap. Several laps may be employed and periodically interchanged to assist this process.

1.1.4 Polishing

Polishing, like lapping, also employs free abrasive. In this case, pressure is applied on the abrasive through a conformable pad or soft cloth. This allows the abrasive to follow the contours of the workpiece surface andlimits the penetration of individual grains into the surface. Polishing with a fine abrasive is a very gentle abrasive action between the grains and the workpiece, thus ensuring a very small scratch depth.

The main purpose of polishing is to modify the surface texture rather than the shape. Highly reflective mirror surfaces can be produced by polishing. Material is removed at a very low rate. Consequently, the geometry of the surface needs to be very close to the correct shape before polishing is commenced.

1.2 ABRASIVES

In all four classes of abrasive machining processes, the abrasive grain must be harder than the workpiece at the point of interaction. This means that the grain must be harder than the workpiece at the temperature of the interaction. Since these temperatures of short duration can be very high, the abrasive grains must retain their hardness even when hot. This is true in all abrasive processes, without exception, since if the workpiece is harder than the grain, it is the grain that will suffer the most wear.

Some typical hardness values of abrasive grains are given in Table 1.1 based on data published by de B...