- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Food and Industrial Bioproducts and Bioprocessing

About this book

Food and Industrial Bioproducts and Bioprocessing describes the engineering aspects of bioprocessing, including advanced food processing techniques and bioproduct development. The main focus of the book is on food applications, while numerous industrial applications are highlighted as well. The editors and authors, all experts in various bioprocessing fields, cover the latest developments in the industry and provide perspective on new and potential products and processes. Challenges and opportunities facing the bioproduct manufacturing industry are also discussed. Coverage is far-reaching and includes: current and future biomass sources and bioprocesses; oilseed processing and refining; starch and protein processing; non-thermal food processing; fermentation; extraction techniques; enzymatic conversions; nanotechnology; microencapsulation and emulsion techniques; bioproducts from fungi and algae; biopolymers; and biodegradable/edible packaging.

Researchers and product developers in food science, agriculture, engineering, bioprocessing and bioproduct development will find Food and Industrial Bioproducts and Bioprocessing an invaluable resource.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Food and Industrial Bioproducts and Bioprocessing by Nurhan Turgut Dunford in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Food Science. We have over one million books available in our catalogue for you to explore.

Information

1 Traditional and Emerging Feedstocks for Food and Industrial Bioproduct Manufacturing

1.1 INTRODUCTION

Many industrial products, such as dyes, inks, paints and plastics, were made from biomass generated by trees, vegetables or other crops during the early 1900s. By 1970, petroleum-based products had largely replaced bio-based products. The utilization of plant-based materials decreased from about 35% to less than 16% between 1925 and 1989 (Forward, 1994). Waning interest in bio-based products was due to the relative ease and lower cost of manufacturing similar products from petrochemicals.

The petrochemical industry has been very successful in developing new products (more than 100 000 commercial products) (Metzger and Eissen, 2004). About 2.6 million barrels per day of petroleum equivalent are used for production of chemicals and industrial building blocks. More than 95% of the world’s petrochemical production is derived from oil or natural gas (Weissermel and Arpe, 1997). Excessive reliance on non-renewable energy and resources is the major problem facing petrochemical industry today. In 2001 it was projected that the global oil reserves would last for about 40 years (Metzger and Eissen, 2004). Oil production is expected to reach its maximum in this decade, at the latest by 2015–2020, and then slowly decrease. According to Gavrilescua and Chisti, the issues that make the petrochemical industry unsustainable in the long run are: (1) utilization of manufacturing techniques that are not environmentally benign or safe, (2) production of toxic by-products and waste, (3) products are not readily recyclable and biodegradable after their useful life, and (4) social benefits of the production are not broadly accessible due to excessive regional concentration of production (Gavrilescua and Chisti, 2005).

Nearly one billion of the current world population (the total is about six billion) live in the industrialized countries. The world population is expected to reach to about nine billion by 2050. It is anticipated that the population growth will mainly soar in the developing countries (Metzger and Eissen, 2004). As the population and the standard of living increase, demand for food and other goods will substantially grow, consequently exerting tremendous pressure on resources. Today it is true that “hunger is a problem of poverty rather than absolute food scarcity” (Koning et al., 2008). Yet, the global demand for food production will more than double by 2050, competing for resources needed to grow biomass for other purposes, including biofuels and bio-based non-food industrial products (Koning et al., 2008). A combination of further increases in crop yields (about 2% per year) and doubling or tripling of resource use efficiencies (especially of nitrogen and water productivity in biomass production systems) will be necessary to meet the rapidly growing demand for food, feed and industrial bioproducts over the next 20–30 years (Spiertz and Ewert, 2009).

About 224 × 109 tonnes of dry biomass is generated globally as a result of photosynthesis (Champagne, 2008). Today, forestry products and agricultural crops are the major feedstocks for bioproduct manufacturing. Utilization of agricultural residues, forestry, animal and municipal solid wastes and marine vegetation as feedstock could ease the pressure on agricultural land needed to grow food. However, the effect of excessive biomass removal on ecosystems has to be examined very carefully.

In this chapter, current and potential feedstocks for food and bioproduct manufacturing will be reviewed under three categories: grain, oilseed and lignocellulosic biomass, which will include grasses and trees. Microalgae, emerging as a biomass source, will be covered in another chapter of this book.

1.2 GRAIN CROPS

Grain crops, specifically cereal crops, are major feedstocks for the food and fermentation industry because of their high starch and protein content. Cereal crops are by far the most important crops cultivated globally. In 2009 about 2.5 billion tonnes of cereals were produced worldwide (FAO, 2010). Wheat, corn, barley and sorghum are the common starch sources that have been traditionally used in food and industrial bioproduct manufacturing. Straw and stocks from cereal crops are also important as lignocellulosic feedstock for bioproduct manufacturing.

1.2.1 Wheat

1.2.1.1 Production

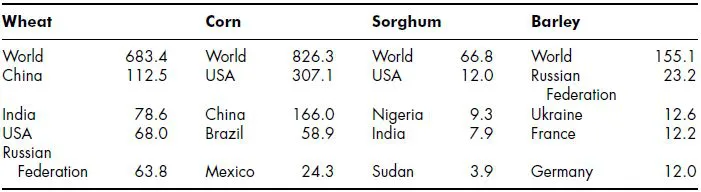

Wheat is one of the major grain crops produced, consumed and traded worldwide. About 683 million tonnes of wheat is produced globally each year (Table 1.1). China, India, the USA and the Russian Federation are among the largest wheat growers (FAO, 2010).

It is believed that einkorn, which was developed from a wild grass native to western Asia, was the first type of wheat cultivated (Atwell, 2001; Orth and Shellenberger, 1988). Four species, Tiriticum: T. monococcum, T. turgidum, T. timopheevi and T. aestivum, are the commercially important wheat cultivars today. Among these, T. turgidum and T. aestivum, which are mainly used for bread and pasta making, respectively, are the most widely grown wheat species (Pomeranz, 1988). Enhancement of nutritional composition and value of wheat through biotechnology is an area that is gaining ever increasing scientific attention. It has been shown that a gene, GPC-B1, found in wild wheat but lost its functionality during domestication has the potential of increasing protein and micronutrient content of cultivated wheat by 10–15% (Uauy et al., 2006). Novel wheat varieties with high amylose content have been developed by using the RNAi gene silencing technique that suppresses the expression of two wheat genes, SBEIIa and SBEIIb (Regina et al., 2006). These genes produce starch branching enzymes and play important role in the starch synthesis pathway. The suppression of these two genes produced a wheat variety with high resistant starch (amylose) content and low glycemic index (GI). This new wheat variety could potentially provide health benefits to people with bowel, diabetes and obesity problems.

Table 1.1 Wheat, corn, sorghum and barley production in 2008 (million metric tons).

Classification of wheat for commercial purposes is based not on variety but on grain properties such as softness/hardness, winter/spring growth habit, red/white bran and protein content. Hard wheat has a hard kernel and produces high protein content flour suitable for making bread and noodles. Soft wheat has lower protein content than hard wheat and is mainly used for making cakes, biscuits and pastries. Winter wheat is planted in late summer or fall and takes the advantage of fall moisture for germination. It is grown in regions where soil does not completely freeze and kill the crop. As the name implies, spring wheat is sown in spring and harvested in late summer. Yields for winter wheat tend to be higher than that for spring wheat due to the risks associated with summer harvest (Pomeranz, 1988). Color, white or red, refers to the color of the outer layers of grain. Depending on milling extraction rate (bran removal rate), the color of the wheat flour can be quite dark, affecting the appearance of the final product. Major wheat exporting countries have their own wheat grading standards that are based on test weight, protein content, moisture, foreign material content and so on (Bushuk and Rasper, 1994). The US Grain Standards Act is enforced by inspectors under the supervision of the US Department of Agriculture (USDA, 2006).

Although wheat straw production yield depends on variety and agronomic and climatic factors, in general 1.3 kg of straw per kg of grain is produced for the most common varieties (Montane et al., 1998). It is estimated that over 90 million metric tons (tonnes) of wheat straw is produced annually in the United States. Considering that world wheat production was about 683 tonnes in 2008 (Table 1.1), global wheat straw production would be 888 tonnes in the same year. About 500 kg of straw per acre needs to be left on the soil surface during wheat harvest for erosion control of steeply sloped ground (Mckean and Jacobs, 1997). It is apparent from these numbers that a significant amount of wheat straw is available for value-added product development.

1.2.1.2 Chemical composition

Chemical composition of wheat fractions varies significantly by variety, agronomic and climatic conditions and separation techniques used. Grain consists of 40–50% of the biomass produced by the crop. Wheat grain structure is very complex and composed of many layers (Godon, 1994). Broadly speaking wheat grain consists of endosperm, bran and germ, which account for 81–84%, 14–16% and 2–3% of the grain, respectively (Atwell, 2001). Whole wheat grain is generally processed by dry milling to obtain flour. Various forms of bran, germ and the “clean-out” of the screen room represent almost 25% of the original wheat grain.

Carbohydrates make up about 60–80% of the dry grain weight. Starch is the main carbohydrate found in endosperm or flour. Other carbohydrates present in wheat include free sugars, glucofructans, cellulose and hemicellulose. Arabinose and xylose are the major free sugars.

Proteins are the second largest group of compounds in endosperm (12–15%). Cereal proteins are classified based on their solubility characteristics; water soluble albumins (5–10%), dilute salt-solution soluble globulins (5–10%), aqueous alcohol soluble prolamins (40–50%) and dilute acid or alkali soluble glutelins (30–40%) (Godon, 1994). Cereal proteins, similar to other plant proteins, are low in some of the essential amino acids, for example lysine. Glutamic acid is the major amino acid in wheat.

Lipids are the minor components of wheat grain (2–3%) and consist of polar and nonpolar components. Triacylglycerides (TAG) make up majority of the nonpolar lipids that are rich in unsaturated fatty acids. Huge variations in linoleic acid content of wheat, 45–75% of total fatty acids, were reported among five market classes of wheat (Davis et al., 1980). Polar lipids include glycolipids and phospholipids (Godon, 1994).

The mineral content of wheat grain varies between 1 and 3%. Even though the mineral content is not very high, wheat could provide significant amount of minerals as it is readily found in most daily diets. Magnesium, phosphorous and potassium are the most abundant minerals. Phosphorous is mostly present in the organic form phytic acid. It has been reported that agronomic condition does not have a significant effect on the mineral composition of wheat grain (Godon, 1994). Wheat grain is rich in vitamins, niacin (about 6 mg/100 mg) and tocopherols (about 20 mg/100 g) (vitamin E).

Wheat bran and germ fractions are rich sources of a number of phytonutrients, including policosanol (PC), phytosterols (PS), α-tocopherol and phenolic acids. A number of studies have shown that PS and PC reduce serum low density lipoprotein (LDL) cholesterol levels (Ostlund, 2002; Hirai et al., 1984; Quilez et al., 2003; Aleman et al., 1994; Castano et al., 2000; Gouni-Berthold and Berthold, 2002). Antioxidant properties of wheat bran and germ extracts are well known (Zhou et al., 2004). It has been reported that dietary wheat bran provides protection against colorectal cancer (Qu et al., 2005). This property is due to the presence of phenolic acids, lignans and flavonoids in wheat bran. Wheat germ contains approximately 11% oil (Dunford and Zhang, 2003; Eisenmenger and Dunford, 2008; Dunford, 2005). The oil contains a number of bioactive compounds, such as tocophero...

Table of contents

- Cover

- Title page

- Copyright page

- Preface

- Contributors

- Abbreviations

- 1 Traditional and Emerging Feedstocks for Food and Industrial Bioproduct Manufacturing

- 2 Recent Processing Methods for Preparing Starch-based Bioproducts

- 3 Protein Processing in Food and Bioproduct Manufacturing and Techniques for Analysis

- 4 Advancements in Oil and Oilseed Processing

- 5 Food-grade Microemulsions As Nano-scale Controlled Delivery Vehicles

- 6 Emulsions, Nanoemulsions and Solid Lipid Nanoparticles as Delivery Systems in Foods

- 7 Fermentation

- 8 Fungal Cell Factories

- 9 Microalgae: A Renewable Source of Bioproducts

- 10 Bioprocessing Approaches to Synthesize Bio-based Surfactants and Detergents

- 11 Biopolymers

- 12 Lignocellulosic Biomass Processing

- 13 Recent Developments in Non-thermal Processess

- 14 Enzymes as Biocatalysts for Lipid-based Bioproducts Processing

- Plates

- Index