- English

- ePUB (mobile friendly)

- Available on iOS & Android

The Packaging Designer's Book of Patterns

About this book

The essential packaging design resource, now with more patterns than ever!

For more than two decades, The Packaging Designer's Book of Patterns has served as an indispensable source of ideas and practical solutions for a wide range of packaging design challenges.

This Fourth Edition offers more than 600 patterns and structural designs—more than any other book—all drawn to scale and ready to be traced, scanned, or photocopied. Online access to the patterns in digital format allows readers to immediately use any pattern in the most common software programs, including Adobe Photoshop and Illustrator. Every pattern has been test-constructed to verify dimensional accuracy. The patterns can be scaled to suit particular specifications—many are easily converted to alternate uses—and most details are easily customizable. Features of this Fourth Edition include:

- More than 55 new patterns added to this edition—over 600 patterns in all

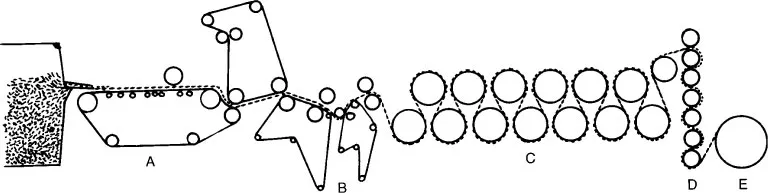

- A broad array of patterns for folding cartons, trays, tubes, sleeves, wraps, folders, rigid boxes, corrugated containers, and point-of-purchase displays

- Proven, scalable patterns that save hours of research and trial-and-error design

- Packaging patterns that are based on the use of 100% recyclable materials

- Includes access to a password protected website that contains all 600+ patterns in digital form for immediate use

Comprehensive and up to date, The Packaging Designer's Book of Patterns, Fourth Edition enables packaging, display, and graphic designers and students to achieve project-specific design objectives with precision and confidence.

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Table of contents

- Cover

- Title Page

- Copyright

- Preface to the Fourth Edition

- Foreword

- Alphabetical List of Patterns

- 1: Introduction

- 2: The Folding Carton

- Trays

- Tubes

- Sleeves, Wraps and Folders

- 3: The Set-Up or Rigid Paper Box

- 4: Corrugated Containers

- 5: Point-of-Purchase Displays

- Glossary

- Bibliography

- Index