eBook - ePub

Geometric Tolerancing of Products

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Geometric Tolerancing of Products

About this book

This title describes the various research results in the field of geometric tolerancing of products, an activity that highlights the difficult scientific locks. The collection is of great importance for further innovation in the development of industrial products.

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Geometric Tolerancing of Products by François Villeneuve, Luc Mathieu, François Villeneuve,Luc Mathieu in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Technology & Engineering Research & Skills. We have over one million books available in our catalogue for you to explore.

Information

Edition

1PART I

Geometric Tolerancing Issues

Chapter 1

Current and Future Issues in Tolerancing: the GD&T French Research Group (TRG) Contribution 1

1.1. Introduction

This book, entitled Geometric Tolerancing of Products, shows that especially in France a wealth of research work exists in this domain. This work highlights some difficult scientific stumbling blocks, the removal of which is of great importance in pursuing innovation in the development of industrial products. For many years this work has appeared limited, in terms of its response to specific problems concerning the different jobs in engineering (design, manufacturing methods, assembly methods, production and control). It is now, however, moving in new directions in the control of product/process integration, helping towards the development of the PLM (product life-cycle management) concept in companies.

Even though the geometric performance of the means of production has progressed enormously over recent decades, geometric variations in the manufactured products exist and probably always will. Certainly the geometric defects observed have diminished in size but they are always there and play an important role in the quality and cost of products. Mastering these geometric variations throughout the product life cycle remains an undeniable performance factor for companies. Moreover, in the “virtual” and simulation era, it is no longer sufficient to design numerical models in CAD representing an ideal geometry. It is becoming increasingly crucial to make a realistic simulation of all of the behaviors, products, manufacturing, assembly, disassembly and control processes, and each of these in 3D. Finally, no model can be validated without being used in a real situation. The important recent developments in dimensional metrology, as much in mechanics as in optics, must also be employed in order to identify the parameters causing the deviations generated by manufacturing processes.

These new challenges for the industrial world have greatly encouraged research into tolerancing and this activity is not new. It was initiated in France in the 1970s in the ENS de Cachan, by Professors Pierre Bourdet and André Clément, among others. Their work revealed research areas to others, thus leading to the creation of research groups across the whole country. The aim of this book is not only to propose a synthesis of the most recent research results of the different French research teams today, but also to offer a shared vision of examples in common resulting from a regular exchange of views that have animated meetings of the Tolerancing Research Group (TRG) since 2001.

1.2. Presentation of the Tolerancing Resarch Group: objectives and function

The first discussions about the creation of the Tolerancing Research Group (TRG) go back to April 2001 at the AIP-Priméca Colloquium, which takes place every two years at La Plagne. The TRG was officially created on April 24, 2001 at the Ecole Normale Supérieure of Cachan, during a work meeting on the occasion of the international seminar on computer-aided tolerancing of the International Academy for Production Engineering (CIRP). François Villeneuve from UJF Grenoble, University of Grenoble, and Luc Mathieu from CNAM Paris created this group, which they head to this day.

One of the motivations for the creation of the TRG was the increasing interest in geometric tolerance and verification, or in other terms for tolerancing and measurement, as much in the research milieu as in the industrial one. This is in contrast to the fact that French research into tolerancing is particularly active all over the country. The first observations on this theme are that it:

– concerns an increasing number of research teams;

– reveals some difficult problems that are still poorly resolved;

– is the object of increasing demand for modeling by the industry;

– generates few tools in the systems assisted by computer (XAO);

– is the object of an international standardization, which is being restructured;

– is particularly well suited to PLM.

The ambition of the TRG is to unite French research in the domain of tolerancing in these industrial and fundamental applications. These objectives consist of:

– comparing points of view on common scientific problems;

– exchanging solutions;

– bringing forward new research themes to respond to the needs of industry and others;

– promoting research into tolerancing and dimensional metrology in France;

– developing research in Europe and defending a certain French school;

– taking the responses proposed to the problems of tolerancing and metrology known to the industry;

– proposing solutions to the normalization organizations;

– producing collected written work in this domain, to respond to the diverse expectations of young researchers, industrialists, teachers and students.

The TRG brings together 10 laboratories and about 30 experienced researchers. Since its creation, the group has worked on very specific subjects, prepared and presented in the framework of a predefined agenda, in order to profit fully from the in-depth exchanges and with a high level of science. Eighteen seminars over two days were organized: Lyon June 2001; Aix en Provence October 2001; Annecy March 2002; Bordeaux June 2002; Grenoble November 2002; Cachan March 2003; Metz November 2003; Annecy May 2004; St Ouen November 2004; Nantes May 2005; Grenoble November 2005; St Ouen May 2006; Aix November 2006; Cachan May 2007; St Ouen May 2008; Nantes November 2008; Bordeaux May 2009; and Metz November 2009.

Minutes were taken for each meeting. The extent of this work led us to write this book: a synthesis of the knowledge mastered by researchers in the group and also a support for future research work. The method of work over the last nine years, where we have compared our opinions while working on case studies in common, has additionally enabled us to provide supportive homogenous examples throughout the different chapters of this book. These examples are presented in section 1.5.

1.3. Synthesis of the approach and contributions of the group

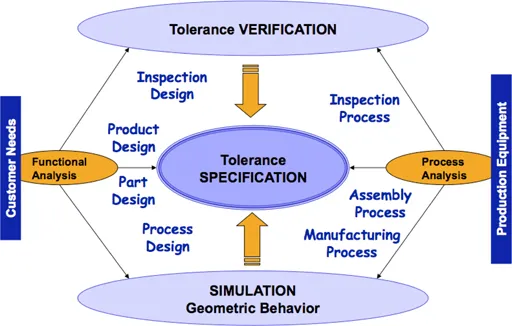

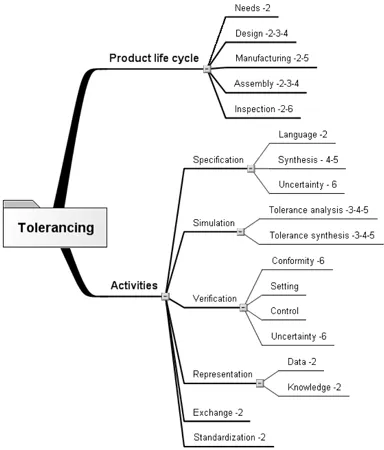

Without trying to be exhaustive, the chapters of this book reflect the present state of knowledge and research in tolerancing in France. The domains of activity and research in tolerancing can be resumed thus (see Figures 1.1 and 1.2):

– The specification of products. This domain tries to define some geometric models for products with defects with the goal of building an unequivocal language of expression of the accepted limits for all people concerned by the control of geometric variations. This work is generally carried out in order to better structure the current standards and exchange language between XAO systems. The second facet of this activity is the determination of the assembly and part tolerances, starting from the conditions of aptitude for use, which can be expressed by functional requirements on the product. It also aims to determine the manufacturing specifications from the functional specifications of the components. This activity is called “tolerance synthesis”, or “qualitative synthesis”.

Figure 1.1. Activity domains and research into tolerancing

– The simulation of the geometric behavior of assemblies with defects. This domain concerns the research into models of tolerance transfer, the optimization of methods and tools for an analysis of the geometric deviations and their consequences. Two types of problems are considered. First the direct problem if we study the consequences of the values of defects influencing the tolerance (tolerance analysis). Second, the inverse problem if we examine the distribution of the required value on influential components (quantitative tolerance synthesis). These tools generally have three objectives:

- to simulate the possibility of assembling the product by evaluating the consequences of deviations of the components on the product and robustness of the assembly;

- to simulate how the product functions under normal conditions of use to determine its aptitude for application;

- to simulate the manufacturing process to verify the feasibility of the functional tolerances, and determine the control tolerances.

– The verification of the specifications or metrology. This research domain consists of finding the measurement equipment and algorithms for controlling and setting manufacturing and assembly equipment. It is important for the declaration of product conformity with respect to specifications in agreement with current standards, and for the validation of simulation models. This measurement equipment and algorithms must give accurate information on the real product situation associated with its uncertainties.

Figure 1.2. Research branches into tolerancing and metrology domains

The different branches of research in the domains of tolerancing are shown in Figure 1.2. This graph is inspired by the work of François Villeneuve and Frédéric Vignat in the PhD thesis of the latter [VIG 05]. It succinctly presents the contributions of the authors of this book, where the numbers in this figure indicate the chapters concerned.

1.3.1. Languages for geometric specification

The second part of this book presents research into the language of geometric specification. It is necessary to talk of “languages” in the largest sense, because in the four chapters the following approaches are covered:

– first, GeoSpelling;

– second, the basis of future propositions in terms of international standards (ISO);

– third, the aspects of the product model for tolerancing;

– fourth, with the view to PLM and finally, the specifications using graphs.

GeoSpelling (Chapter 2) is an answer to the need for an unequivocal language addressing the specification and verification of the products. Furthermore, it is important that it is unified for the macro- and micro-geometry of isolated parts and assemblies using the concepts of specification by dimension and by zone. This comes from the research work essentially led by Alex Ballu, Luc Mathieu and Jean-Yves Dantan. It was presented by French experts and adopted by the ISO GPS (International Organization for Standardization Geometric Products Specification) technical committee. In 2005, it was the subject of the ISO/TS 17450-1 document [ISO 05] The two important points of this model are, first, a model of parts with defects called the “skin model”, and second, a declarative approach to explicitly describe the quantity that is subject to tolerance or measure.

Chapter 3 proposes a product model used on a data structure permitting the management of data useful for tools of dimension chains. It comes from the work on the IPPOP (Product Integration, Process and Organization for the amelioration of Performance in engineering) project, an exploratory project recognized by the National Network of Software Technologies. This project ran from December 2001 to June 2005, and the authors of this chapter participated in it. Its principle objective is to propose a collaborative work environment where the different jobs in the product life cycle can intervene in the tolerancing process. This environment must ensure the traceability of tolerances, and in particular for all transfers from initial functional requirements to disassembly at the end of the product’s life, passing through the stages of manufacture and component inspection. This chapter is based on the research work of Jérôme Dufaure and Denis Teissandier.

The representation of the mechanical assemblies and tolerances by graphs (see Chapter 4) aims at modeling the mechanism structure, links, functions, requirements and tolerances. It visualizes the mechanism cycles used to write the loop-closing equations for the displacements and also allows the representation of key cycles. A representation tool based on graphs was therefore proposed and synthesi...

Table of contents

- Cover

- Title Page

- Copyright

- PART I. GEOMETRIC TOLERANCING ISSUES

- PART II. GEOMETRIC TOLERANCING LANGUAGES

- PART III. 3D TOLERANCE STACK-UP

- PART V. MANUFACTURING TOLERANCING

- PART VI. UNCERTAINTIES AND METROLOGY

- List of Authors

- Index