eBook - ePub

Integrated Product Design and Manufacturing Using Geometric Dimensioning and Tolerancing

- 352 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Integrated Product Design and Manufacturing Using Geometric Dimensioning and Tolerancing

About this book

This book addresses the preparation and application of design layout analyses with concurrent engineering teams in six steps that capture design intent and add value to design process. It offers tools for eliminating costly trial-and-error approaches and deliver economically viable products. The authors discuss product design techniques that allevi

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Integrated Product Design and Manufacturing Using Geometric Dimensioning and Tolerancing by Bob Campbell in PDF and/or ePUB format, as well as other popular books in Mathematics & Applied Mathematics. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction

In an interview given to The Chicago Tribune (Siskel, 1988), filmmaker Howard Hawks noted, “The one thing I’ve learned about making movies is that you can’t fix a film once the shooting begins. If it’s not right in the script, the problems are only bigger as the images move from paper to the big screen.” The design and delivery of manufactured products are much like the making of a movie; both require equal sophistication and art for their execution.

Taking a page from Hawks’ script, this book builds on the idea that once a product is designed it is too late to do anything more than put Band-Aids on production problems. A better way to get a product to market is to design it within a tightly integrated system and avoid these problems completely. Success comes from anticipating the interaction of the product design and the elements of production during the design phase when it is still economically feasible to make changes.

Previously such a design goal would have required the product engineer to be versed in design, engineering analysis, production techniques, quality assurance, reliability, and too many other disciplines to mention. The poor soul chosen to train in these areas would wind up with lots of gray hair and a short professional life. Furthermore, it would be dangerous for the company to concentrate this knowledge in a single individual when risks associated with the person’s longevity, professional or otherwise, are considered. Of greater concern is the fact that allowing one individual to amass this proprietary knowledge makes it likely that it will not be formally documented and thus eventually lost. An integrated product development system provides the sole opportunity to eliminate or reduce such risks.

With the advent of low-cost computing power and relatively inexpensive networking software, integrating the phases of the development cycle can now be easily achieved. The design of a product can be approached systematically rather than through the piecemeal methods of the past. The challenge now is to understand the limitations of these systems. Product development organizations must realize that control is not always added by new management techniques and technology; rather, risks may be increased by using techniques that give a deterministic world view where one does not exist. Because the product’s architecture is designed through a variety of technologically supported methods, different tools must be used in making the detailed decisions necessary to bring the product to physical reality. The responsibility passes from the “thinkers” to the “doers”—from the managers to the designers and engineers.

With this in mind, our book introduces a set of geometric techniques that can be incorporated within an integrated product development system. In fact, they are paramount to its success. The reader is given sufficient exposure to these methods to judge their validity and intelligently apply them. Each manufacturing situation is unique and requires creative and concurrent design of the product and the production system. As a consequence, the text is directed toward understanding the design phases of integrated product development. The resulting geometric viewpoint will allow the student or practitioner to create a product definition—encompassing both the product and the manufacturing processes— appropriate to the task.

An example helps to understand the magnitude of the problems that need to be resolved. One of the authors was hired to evaluate the design of a plainpaper copier when it was nearly ready for production release. A group of engineers from quality and manufacturing was looking at individual detail drawings for the first time, although the project was 30 months old. The engineers were dutifully signing off without the benefit of either a design layout or an assembly drawing. Without one or the other, no one had any way to determine the spatial relationships of the components.

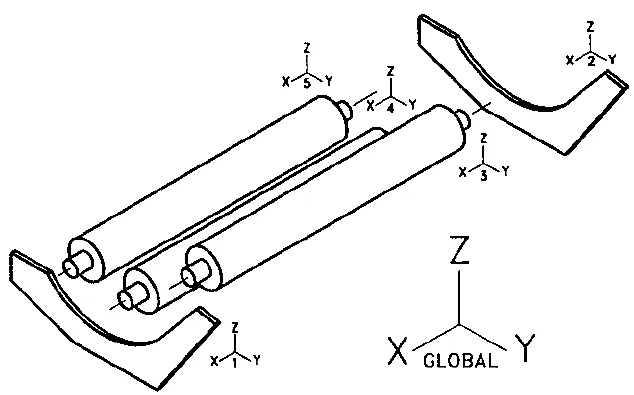

These missing relationships are best illustrated by Figure 1-1, an exploded view of a similar situation that demonstrates the geometric relationships in a simplified assembly. Each of the components in the illustration has its own coordinate system (i.e., a datum reference frame). For both function and assembly, these coordinate systems must eventually be related or linked together and placed within a global system that defines the final assembly of the product. In the copier situation, this was not done.

Assuming for the sake of argument that all the rolls have sufficiently perfect geometric form to function properly, the spatial location of the roll axes can still defeat the design by being either mislocated or misaligned. The required relationships depend on accurately locating the mounting features in the frames. These frames are normally a series of mounting surfaces made from sheetmetal and plastic that connect to each other in a chain of subassemblies. In turn, the series of subassemblies mate to create the complete assembly. Any lack of geometric definition (e.g., axis location) can lead to large tolerance stackups, causing successful assembly to occur only by chance rather than by plan.

FIGURE 1-1 Illustrating a series of reference frames that must be linked for function and assembly.

An examination of the engineering drawings revealed that the designs did not include any primary datums (reference features that aid in describing geometric location and relationship), which were necessary for an adequate review of the detail designs and an understanding of the desired geometry. This was astounding given the fact that the engineers had used the ASME graphics standards to define the product. More than 100 instances were related to applications of geometric control where primary datums were required but not provided. The specification of a primary datum was absolutely necessary in each of these instances to ensure functional conformance.

The preliminary analysis also indicated that the parts were dimensioned in such a way that their location was not defined relative to the copier drum. The engineering release was stopped and seven drafters were put to work locating these parts. From the information originally provided, five of the parts could not be positioned in the assembly because of implied, incomplete, or conflicting datums.

Several months later, after all the existing managers responsible for the components had been replaced, the project was out of control and the firm contacted a Japanese company to redesign and manufacture the copier. The marketing window was missed by two years, but the company finally got to put its name on a copier. This is only one instance of office products this division designed over a 10-year period—and all of them were found to be unmanufacturable. With a success rate like this, it is easy to understand why the division no longer exists and why thousands of employees in a small town lost their jobs.

To avoid similar problems, this book presents a number of tools that have been around for many years, at least in simplified form. Nothing illustrated here is based on radically new theories or technologies. Instead, the book offers a series of simple, yet elegant, methodologies that complement the best design and organizational techniques. Without straining credibility, these design methods will support any of the existing or likely techniques that management gurus offer. Be it total quality management, team building, design for assembly, agile manufacturing, or any of the myriad of ideas that come and go, the fundamentals required to deliver a product to the customer do not change. At each stage of the design and manufacturing processes, these basic steps must be undertaken. This book provides a mechanism to efficiently get through the cycle for a specific project.

The book is founded upon the concepts in the ASME Y14.5M dimensioning and tolerancing standard but goes beyond the usual drawing annotation applications. It specifically shows how these techniques may be extended to create elements of a design methodology. This methodology can then be employed in the simultaneous design and definition of a manufactured product and the processes necessary to produce it. The benefit of the standard is that it forces recognition of the variability of the design and production processes much earlier in the cycle than is currently done. The result is that function, durability, manufacturability, assembleability, and cost are considered throughout the development process.

Additionally, the book advocates that the standard be used as the primary medium of communication. Used in this manner, the standard links the various members of the concurrent engineering team, allowing them to communicate the unique definition necessary to transform the product concept into an economically effective production system. All subsequent product and process decisions are derived from this definition. The communication techniques and the organizational structure are intimately intertwined and are the key to project success.

The effective application of the methodologies offered here requires knowledge of the Y14.5M standard. This book is written in as general a fashion as possible to allow the presentation of these concepts to a larger audience, but extensive study and experience are needed to reap the vast economic benefits that can be obtained by their use. The book does not provide a detailed exposition of geometric controls. It does show, particularly through example, how the integrated approach coupled with geometric control may be used to add strategic value to product development functions.

In writing the book, the authors have drawn from the sections of the standard that support state-of-the-art manufacturing with an emphasis on single-setup processing. The resulting techniques provide a complete and uniform definition that is the hallmark of a well-engineered product development system.

Since existing design systems rely on the specialized knowledge of individual practitioners, it is necessary to look for a mechanism—a structure—that will serve to integrate the various disciplines (i.e., cross-functional teams) and still accomplish the goal of designing the product and the process simultaneously. The advantage of incorporating this structure in a team-based environment is that it leaves the individuals comprising the system free to retain their professional identities. This eliminates the inevitable compromises that will occur in the development of cross-functional individuals capable of dealing with these disparate disciplines.

Subsequent chapters describe the framework of the system and develop, through example, the various techniques that are its logical extension. Where possible, actual examples are used to illustrate basic concepts and show that they can be successfully implemented when applied in the industrial environment. What follows will provide a valuable strategic tool for all product development organizations. Be forewarned that the material requires conscientious study and continuous application for success. The steps in this book are but the beginning of a learning process that never ends.

REFERENCE

Siskel, G. Screen Gems Film’s Finest Reveal the Secrets of Their Success, Chicago Tribune, 4 December 1988, Final Edition, sec. C, p. 32.

2

What Are the Techniques?

2.1 INTRODUCTION

The world of manufacturing thrives on continuous engineering change; only those firms that can react to these product changes and quickly fulfill the demands of the marketplace survive. To meet such a challenge, a variety of tools are necessary. This chapter highlights two tools being advocated and shows how they can be woven into a design methodology that reduces the total cost of product development.

The first of these tools involves the early and complete definition of the product and its supporting manufacturing processes. This requires a logical and disciplined approach to the design of the product and its allied systems if product development is to approach more of the science than the art of manufacturing.

The second tool concerns the organizational structure, a team-based environment, required to both provide and implement the product definition. Without this organizational foundation, only rare firms would have individual employees with sufficiently broad ranges of knowledge capable of using the methodology. Absent such individuals, the design process either would take too long to be successful in the marketplace or would not yield an adequate product design if done in a timely fashion.

These tools address a pair of distinct concerns related to product design—one of a technical nature and the other organizational. Both tools must be implemented simultaneously to achieve the desired ends. In all likelihood, the separate implementation of either one will not achieve the anticipated effects and may possibly make the product development process even more inefficient.

2.2 PRODUCT DEFINITION

Early in the historical development of interchangeable manufacturing, the end product was not completely defined in any formal manner prior to deciding what manufacturing methods would be used. Reducing engineered items to a precise graphical form (including tolerances) as a separate phase preceding production is a relatively recent occurrence (Ferguson, 1992) that can be traced back only to the latter part of the 19th century.

This was particularly true under the “contractor” system of manufacture (American Machinist, 1978) where the contractor was responsible for the design, manufacture, and delivery of the product. With this method of procurement, it was not unusual to find both design and manufacturing skills embodied in the same individual, as is still the case in Japan and Europe. The contractor would have anticipated many of the problems encountered in the manufacture of the product. As the contractor gave the product its final definition, he or she was also anticipating the design of the manufacturing system. Problems that would normally arise when responsibilities for design and manufacture are lodged in different individuals would be reduced or eliminated. The contractor, who had an immediate economic stake in the overall system design, was one of the earliest practitioners to apply concurrent engineering to volume production.

The advent of mass production and formalized programs of engineering study led to the separation of the design and manufacturing functions. With the enhanced scientific base that was incorporated into engineering programs around the mid-20th century, the severing of these functions was almost complete. Many of the current organizational management techniques, in both the human resources area and financial management, create the apparent need for this type of specialization.

It has been the authors’ experience that disciplinary-driven walls exist in most firms, separating the design and manufacturing departments. Where this is the case, parochial and political interests prevent either of these disciplines from intruding into the other’s area. The present organizational structure of many firms increases this isolation and makes it difficult to optimize the design of the product, or its production system, early in the design cycle. An additional factor that serves to reinforce this tendency is the serial nature of the design process as it has traditionally been practiced in the United States. The work of each functional department must be completed before the inputs to the next functional area are prepared and released. As a consequence, almost all stages of product development are critical in nature.

With the major design tasks on the critical path, the underlying design process becomes iterative and its elements interdependent. There is a constant give-and-take in the design of the product that affects previous decisions and decisions yet to be made. Once a preliminary design has been created, seemingly minor engineering changes can have a major impact on other elements of the product delivery system. This presents a multitude of problems, many resulting from the nature of existing organizational structures and reward systems that do not encourage dynamic interaction between design and manufacturing.

Thus, education, training, and organizational techniques have isolated many departments, making it difficult for them to communicate with each other. This lack of clear communication has particularly dire consequences when it involves the design and manufacturing departments. The further one is in the development process when design and manufacturing begin true exchanges of information, the more expensive implementation of the design becomes. This increase in expense can be expressed monetarily and in terms of time-to-market.

In creating any product, the principal criteria used in decision making involve the functional requirements necessary to satisfy market needs. These requirements can range from the utilitarian to the cosmetic. The specific techniques used to create the final product are all derived from functional specifications. One goal of the engineering process is to communicate the design intent embodied in these functional specifications. This communication should contain sufficient detail to ensure that any decisions made in implementing production will maintain the integrity of the envisioned design.

Current practice relating to the design of interchangeable products begins with the creation of concept layouts to provide designers, drafters, and management with graphical methods of visualizing the proposed product. As the design cycle proceeds and the preferred design concepts are chosen, a preliminary design layout is created that begins giving definition to the functional features of the assembly. As production is approached, the design layout is transformed into a detailed representation of each component that comprises the product. Throughout this process, the original design intent must not be obscured by the communication and documentation techniques or by alternative design interpretations introduced by these techniques.

Another factor that compounds the difficulty encountered in product development is the specialized knowledge lodged in many of the firm’s functional departments. The parochial interests of these functional areas may serve to discourage rather than enhance both communication and recognition of the common organizational goals. The typical consequence is to take manufacturing out of the loop at the most critical phases of product design.

Until World War I it was common practice to use models of a product or its components produced by individuals with both design and manufacturing skills (Hounshell, 1984). A model could serve both as a prototype that would lend itself to experimental purposes—functional and process related—and as a definition of the desired end product. However, while it was advantageous to have this physical model available, the technique engendered some disadvantages as production became more decentralized with design and manufacturing separated by both time and distance. The model would now have to be replicated with a high level of precision and accuracy for use at a remote site. Any alteration to the model (i.e., the product definition) involved expensive and time-consuming changes.

When contrasting more recent use of working drawings to specify the product with an earlier reliance on a physical model, it is apparent that the use of graphical techniques to communicate design intent has a major impact on delivery of an acceptable product. The very nature of the physical model required consideration of manufacturing methods when fabricati...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Foreword

- Preface

- Acknowledgments

- 1 Introduction

- 2 What Are the Techniques?

- 3 The Basis of the System

- 4 Design Layout

- 5 A Producible Component

- 6 First Steps Toward Production

- 7 Dimensional Measurements

- 8 Inspection and Verification

- 9 Functional Gaging

- 10 Functional Gage Tolerancing

- Appendix 10.A

- 11 Functional Inspection Techniques

- 12 Functional Workholding and Fixturing

- 13 Does It All Work?

- 14 Implementation and Process Improvement