eBook - ePub

Principles of Modified-Atmosphere and Sous Vide Product Packaging

Jeffrey M. Farber, Karen Dodds, Jeffrey M. Farber, Karen Dodds

This is a test

Share book

- 464 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Principles of Modified-Atmosphere and Sous Vide Product Packaging

Jeffrey M. Farber, Karen Dodds, Jeffrey M. Farber, Karen Dodds

Book details

Book preview

Table of contents

Citations

About This Book

This is the first in-depth presentation in book form of both modified atmosphere and sous vide food preservation and packaging technologies and applications. The use of these technologies with all applicable food product categories is examined. The authors are specialists in these preservation/packaging methods from North America and Europe. All significant aspects are examined including processes and materials, applications, microbiological control, and regulations and guidelines. Topics of special interest include use of hurdles, HACCP, gas absorbents and generators, and time-temperature indicators. Extensive practical reference data is economically presented in tables.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Principles of Modified-Atmosphere and Sous Vide Product Packaging an online PDF/ePUB?

Yes, you can access Principles of Modified-Atmosphere and Sous Vide Product Packaging by Jeffrey M. Farber, Karen Dodds, Jeffrey M. Farber, Karen Dodds in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Food Science. We have over one million books available in our catalogue for you to explore.

Information

CHAPTER 1

Introduction

KAREN L. DODDS–Health Canada, Ontario, Canada

CONSUMER demand for a wide variety of fresh, minimally processed, convenience foods has increased rapidly over the last two decades, with no down-turn in sight. Several important factors have influenced this demand, including consumers’ concerns and perceptions of health risks associated with the use of preservatives in foods, specifically concerns to reduce the dietary intake of salt due to its implication in coronary heart disease, and concerns to reduce nitrite due to the association of nitrosamines with cancer, the increasing number of families with both parents working, and an increasing disposable income. This book focuses on two technologies being widely used to respond to this demand: modified atmosphere packaging and sous vide technology. Both these technologies extend product shelf life beyond that of truly fresh foods, while usually avoiding the use of chemical preservatives. These technologies have seen incredible growth over the last two decades, both in North America and Europe (see Chapters 2 and 3), and have not yet reached their full potential. Some estimates predict that more than half of all food consumed will be in these categories by the year 2000 (Downes, 1989).

MODIFIED ATMOSPHERE PACKAGING

A general definition of modified atmosphere packaging (MAP) simply means packaging a food so that the atmosphere is different from the normal composition of air (78.08% N2, 20.96% O2, 0.03% CO2, variable amounts of water and traces of inert gases). Under this general definition, several packaging techniques are included, such as vacuum packaging, controlled atmosphere packaging and modified atmosphere or gas packaging. Vacuum packaging is perhaps the most common method of modifying the internal package atmosphere. In vacuum packaging, the product is placed in a package of low O2 permeability, the air is evacuated and the package sealed without delierate replacement with another gas mixture. Typically, an atmosphere with elevated levels of CO2 develops as the food product and contaminating microorganisms consume residual O2 and produce CO2. Controlled atmosphere packaging includes systems to maintain a certain atmosphere around the product. At present, this application tends to be limited to storage in the warehouse or in bulk packs. Modified atmospheres may be established by gas flushing at the time of packaging, or by allowing air-packed products, mainly fruits and vegetables, to generate a modified atmosphere as a result of natural respiration. As well, additives incorporated into the package, such as O2 scavengers or emitters or CO2 absorbers, are capable of modifying the atmosphere after packaging (see Chapter 14).

The use of modified atmospheres to extend the shelf life of foods has a considerable history. Initially, commercial applications were largely confined to controlled atmosphere storage and transport of bulk commodities. Much of the original work was done in Australia and New Zealand in the early 1930s, when beef and lamb carcasses were first shipped to the U.K. under CO2 storage (Gill, 1986). Controlled atmosphere storage warehouses were designed and implemented in the 1940s and 1950s to extend the shelf life of fresh apples (Zagory and Kader, 1988). The use of MAP technology received a significant boost when the retail chain of Marks and Spencer introduced a wide range of fresh MAP meat products in the U.K. in 1981.

Controlled atmosphere packaging for fresh fruits and vegetables was named one of the 10 most significant innovations in food science between 1939 and 1989 by the Institute of Food Technologists (Anon., 1989). The use of reduced levels of O2, selective mixtures of gases or increased CO2 to limit respiration and ethylene production, thereby delaying ripening and decaying and increasing the shelf lives of refrigerated produce, has had a significant impact on the fresh produce industry. Development of packaging systems and films that are selectively permeable to specific gases was a key element in the development of this application and its extension to a wide variety of products.

Modified atmospheres extend the shelf life of foods by inhibiting chemical, enzymatic and microbial spoilage. This allows preservation of the fresh state of the food without the temperature or chemical treatments used by other shelf life extension techniques such as canning, freezing, dehydration and other processes.

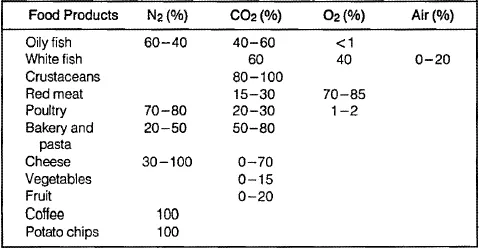

The gases used in most MAP applications include CO2, O2 and N2, but different products require different combinations of these gases (Table 1.1). The role of CO2 is primarily to inhibit the growth and metabolism of microorganisms. CO2 selectively inhibits the growth of gram-negative bacteria (Enfors and Molin, 1981), which typically grow relatively rapidly and produce the off-flavours and odours associated with spoilage of many foods, such as the spoilage of meat associated with growth of Pseudomonas spp. Bacteria such as the lactic acid bacteria are relatively unaffected by CO2, and they continue to grow but tend to decrease the rate of spoilage. The ability of a CO2 atmosphere to extend the shelf life of beef was demonstrated as early as 1882, when beef was kept for 18 d in hot summer weather with daytime temperatures up to 32°C (Kolbe, 1882; cited by Dixon and Kell, 1989). By 1938, 26% of the beef from Australia and 60% of that from New Zealand was shipped under CO2 (Dixon and Kell, 1989). For fresh produce, the level of CO2 must be carefully determined, as exposure to levels above a tolerance limit can cause physiological damage to the produce (Zagory and Kader, 1988). CO2 is both water and lipid soluble and thus dissolves in the product to some extent. The addition of O2 depends upon the product. O2 is primarily used for fresh red meats to maintain the desirable colour. Again, for fresh produce, the level of O2 must be carefully determined, as levels which are too low may increase anaerobic respiration and lead to development of off-flavours due to the production of ethanol and acetaldehyde. O2 is not used for fish high in fat content, such as mackerel and herring, to prevent rancidity problems, and it is not used for cured meats since it has a detrimental effect on product colour. N2 is an inert tasteless gas with low solubility in water which is often used as a filler.

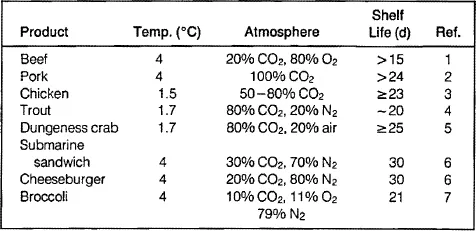

Almost any type of food product is currently available packed under a modified atmosphere, including red meats and poultry, both raw and cooked (see Chapters 6 and 7), fish (see Chapter 8), a wide range of vegetable and fruit products (see Chapter 9), fresh pasta, breads, cakes, pizza and other baked goods (see Chapter 10), combination products and whole meals, snack foods, and dried foods. The length of refrigerated shelf life which can be obtained is impressive (Table 1.2).

A major concern regarding the widespread use of MAP is its safety. The ability of MAP to inhibit spoilage organisms is well documented, but many pathogenic organisms are less affected (Genigeorgis, 1985; Hintlian and Hotchkiss, 1987; Farber, 1991). Therefore, there is concern that a MAP product may become potentially hazardous before it is overtly spoiled. Indeed, the delay in spoilage gives many contaminating pathogens an extended period of growth. This question is especially important for the psychrotrophic pathogenic organisms such as listeria monocytogenes, nonproteolytic Clostridium botulinum, Aeromonas hydrophila and Yersinia enterocolitica which can all grow at refrigeration temperatures. Further, it is well documented that it is difficult to maintain adequate refrigeration throughout the food chain, particularly at the retail and consumer level. Retail display cases are often at temperatures of 7 – 10°C, while the temperature in home refrigerators may even exceed 10°C (Conner et al., 1989). Therefore, pathogens which can grow at temperatures of mild abuse, such as 5–12°C, are also a concern. These include Salmonella, proteolytic C. botulinum, Clostridium perfringens, Bacillus cereus and Staphylococcus aureus. Holding product at abuse temperatures also means the growth rate of psychrotrophic pathogens will be increased. Various studies have shown that toxigenesis by C. botulinum can precede spoilage of MAP products, especially under conditions of temperature abuse (Lambert et al., 1991).

References: 1) Shay and Egan, 1987; 2) Enfors et al., 1979; 3) Gardner et al. 1977; 4) Barnett et al., 1987; 5) Parkin and Brown, 1983; 6) Farber, 1991 ; 7) Berrang et al., 1990.

There are several benefits to the use of MAP beyond shelf life extension. MAP products can be prepared centrally and distributed, ready packed, to retailers. The product can often be produced more economically due to large scale production and better utilization of labour and equipment. MAP can increase product utilization, improve inventory control, provide better distribution of product to target markets, and reduce space costs. The sales appeal of the product may be enhanced due to attractive colour and presentation. The use of sealed packs improves hygiene throughout the distribution and retail chain.

SOUS VIDE TECHNOLOGY

It is not surprising that the technology now known as sous vide was developed in France, a country known for gastronomy. While the literal translation of the French term into English simply means “under vacuum,” sous vide has implications beyond that. The commonality in sous vide products is that foods, either raw or precooked, are packaged under vacuum in hermetically sealed bags, then cooked or heated, and finally cooled and refrigerated (see Chapters 3 and 10). The majority of them share the following characteristics: 1) they are precooked, packaged products which require little or no additional heat treatment prior to consumption; 2) they have an extended refrigerated shelf life; 3) they are not usually protected by conventional preservation systems, such as a low pH or low water activity; and 4) they are marketed in sealed packages or containers. The sous vide process was developed, many will say “reintroduced” by a chef, Georges Pralus, to improve the flavour, appearance and aroma of prepared foods. This system was initially used for many hospitals, catering units and restaurants, but it is now being extended towards production for retail sale.

Cooking foods in their own juices in a hermetically sealed bag improves product quality for several reasons. Cooking a product in water or steam allows more efficient transfer of thermal energy than in air, and also allows better control of cooking temperature. Therefore, the heating requirement is often reduced and better product consistency and nutritional value are maintained. Because water does not need to be added and steam is not allowed to escape, the original flavour of the product is better preserved. As well, if the product is seasoned with herbs or spices, the organoleptic qualities are improved. While the cooking was originally intended to improve the organoleptic qualities of the product, it can serve as a pasteurization step, inactivating the vegetative microbial population in the product. Finally, because the product is kept in the hermetically sealed bag, there is a reduced risk of post-processing contamination. These last two factors generally result in an extension of refrigerated shelf life.

Typically, the sous vide process includes six steps (Figure 1.1). The first involves preparation of ingredients and/or components. There is general agreement that only top quality fresh raw ingredients should be used. The preparation may include blending or cooking of sauces; grilling or searing of meat, poultry or seafood; blanching of pasta, vegetables, etc. The components are then assembled and packed in preformed or thermoformed pouches or trays, before the packages are sealed under vacuum. The vacuum-sealed food is cooked under precise conditions in steam chambers, retorts, water-submersion tanks or cascading water-fall baths. Unlike conventional canned foods, the thermal process applied to sous vide products is minimal, resulting in a product which is not shelf stable and which requires refrigeration or freezing. The product is then rapidly chilled to stop the cooking process, and finally stored under...