eBook - ePub

Sustainable Food Systems from Agriculture to Industry

Improving Production and Processing

- 442 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Sustainable Food Systems from Agriculture to Industry

Improving Production and Processing

About this book

Sustainable Food Systems from Agriculture to Industry: Improving Production and Processing addresses the principle that food supply needs of the present must be met without compromising the ability of future generations to meet their needs. Responding to sustainability goals requires maximum utilization of all raw materials produced and integration of activities throughout all production-to-consumption stages. This book covers production stage activities to reduce postharvest losses and increase use of by-products streams (waste), food manufacturing and beyond, presenting insights to ensure energy, water and other resources are used efficiently and environmental impacts are minimized.

The book presents the latest research and advancements in efficient, cost-effective, and environmentally friendly food production and ways they can be implemented within the food industry. Filling the knowledge gap between understanding and applying these advancements, this team of expert authors from around the globe offer both academic and industry perspectives and a real-world view of the challenges and potential solutions that exist for feeding the world in the future. The book will guide industry professionals and researchers in ways to improve the efficiency and sustainability of food systems.

- Addresses why food waste recovery improves sustainability of food systems, how these issues can be adapted by the food industry, and the role of policy making in ensuring sustainable food production

- Describes in detail the latest understanding of food processing, food production and waste reduction issues

- Includes emerging topics, such as sustainable organic food production and computer aided process engineering

- Analyzes the potential and sustainability of already commercialized processes and products

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Sustainable Food Systems from Agriculture to Industry by Charis M. Galanakis in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Agriculture. We have over one million books available in our catalogue for you to explore.

Information

Part B

Sustainable Food Processing

6

Energy Saving Food Processing

Shahin Roohinejad⁎,†; Oleksii Parniakov‡; Nooshin Nikmaram§; Ralf Greiner⁎; Mohamed Koubaa‡ ⁎ Department of Food Technology and Bioprocess Engineering, Max Rubner-Institut, Karlsruhe, Germany

† Shiraz University of Medical Sciences, Shiraz, Iran

‡ University of Technology of Compiègne (TIMR - EA 4297), Compiègne, France

§ Islamic Azad University of Sabzevar, Sabzevar, Iran

† Shiraz University of Medical Sciences, Shiraz, Iran

‡ University of Technology of Compiègne (TIMR - EA 4297), Compiègne, France

§ Islamic Azad University of Sabzevar, Sabzevar, Iran

Abstract

One of the challenges to increase the profitability in the food industry is to reduce the consumption of energy. Energy is mainly consumed by either increasing or decreasing the temperature during the different processes. A known strategy to recover a part of the consumed energy is to regenerate heat during product's cooling, to preheat the untreated products. To improve energy saving efficiency, many other techniques have been proposed either in the literature or already implemented in the processing chain of food products. These techniques, applied either alone or combined with existing ones, include electrotechnologies (i.e., pulsed electric fields), microwaves, ultrasounds, pulsed light processing, high-pressure processing, and some other technologies that are discussed herein. With regard to the diversity of unit operations in the food industry, this chapter mainly deals with analyzing the energy saving using these novel technologies in pasteurization and sterilization, extraction, evaporation and dehydration, and chilling and freezing. The mechanisms of action of the described technologies as well as their advantages and disadvantages are discussed.

Keywords

Energy saving; Food processing; Emerging technologies; Pasteurization; Drying; Freezing; Extraction

Acknowledgment

The first author (Shahin Roohinejad) would like to acknowledge the Alexander von Humboldt Foundation for the postdoctoral research fellowship award.

1 Introduction

Energy efficiency enhancement is always considered as a challenging issue due to different reasons (e.g., higher greenhouse gas emissions). Three major solutions could be taken into account: firstly, employing more efficient behavior, secondly, utilization of alternative fuels or production/transport/consumption routes that provide the same service while consuming lower energy, and finally replacing some novel technologies instead of the conventional energy-intensive operations (de Mello Santana & Bajay, 2016). The food industry (the fifth biggest consumer of energy in the United States) is among those industries that need to be improved in terms of energy consumption, as a significant amount of machinery and energy is applied in food processes during the conversion of edible raw substances to higher-value food products. Energy efficiency enhancement in the food industry should be evaluated in both technical and financial aspects to be feasible and practical (Wang, 2014).

One of the most energy consuming unit operations used in the food industry is thermal processing including pasteurization, sterilization, dehydration, drying, chilling, and freezing. During these processes in the conventional way, heat is transferred to the food material through convection, conduction, and radiation. By contrast, there are other effective methods of heat transfer effected by implementing novel technologies (Wang, 2014). Application of these food processing techniques can reduce the energy consumption and consequently decrease the production cost and enhance the sustainability of food production. Generally, emerging technologies are divided into two main categories including: (1) thermal (e.g., ohmic heating (OH)) and (2) nonthermal processing (e.g., high-pressure processing, electrotechnologies, and irradiation). Different mechanisms applied during these methods such as electromagnetic, electric field, and pressurization resulted in better heat transfer than conventional methods (Pereira & Vicente, 2010). In addition to saving energy, most of them also lead to water saving, reliability increment, emissions lowering, better product quality, and productivity enhancement (Masanet et al., 2008).

In this chapter, the principles and mechanisms of several novel thermal and nonthermal technologies for energy saving in food processing are reviewed. Among their different utilization in various food processes, their applications for pasteurization, sterilization, evaporation, dehydration, chilling, and freezing are highlighted. Finally, the benefits and challenges of these novel technologies are introduced and discussed.

2 Energy Consumption for Conventional Processing of Food Products

Energy consumption during the processing of food products is highly dependent on the type of product being processed. For instance, the energy consumption is equal to 9385 MJ for making one ton of milk powder, and 9870 MJ for making 1 ton of whey powder, whereas only 2 MJ of heat are required to produce 1 ton of pasta (Bundschuh & Chen, 2014). In addition to the product properties, many other factors influence the energy consumption in the food industry including the type of equipment, the infrastucture, the ambient temperature, and the skills of the operators.

2.1 Pasteurization and Sterilization

2.1.1 Pasteurization

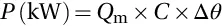

Pasteurization is considered as one of the main unit operations applied to improve the microbiological quality of a food product. Conventional pasteurization allows the destruction by heat of most of the heat-sensitive microorganisms causing food spoilage but at the same time, it causes the degradation of the sensory and nutritional attributes of the food products. The energy required for heat during processing depends on the fluid type (specific heat of fluid, C (kJ/kg°C)) and the mass flow (Qm (kg/s)), the difference between inlet and outlet temperatures (Δθ (°C)), and the time (t (h)) required for pasteurization. This could be determined using

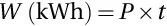

where P (kW) is the consumed power (1 kWh = 3600 J), which could be calculated using

To save energy, the heat applied for pasteurization is typically used to warm the cold product. For instance, raw milk is usually heated from a chill temperature (i.e., 4°C) to 72°C for pasteurization for 15 s, before being chilled again to 4°C. The hot product (after pasteurization) is used to warm-up the cold one in countercurrent circulation, which leads to precooling the pasteurized product, and preheating the raw one, which helps to save the refrigeration and heating energy. The process takes place in a heat exchanger that is called either regenerative heat exchange or heat recovery (Fig. 1). In most of the cases, this recovery process leads to recycle up to 95% of the heat content of the pasteurized product. Mastering the heat recovery process is of great importance as it allows saving significant quantity of energy. For instance, the steam required for pasteurization could be reduced from 0.012 to 0.003 kg/L of product, when the regeneration percentage increases from 80% to 95%. Although widely used, pasteurization is not able to kill the spore-bearing organisms, such as thermophilic Bacillus subtilis, and in many cases, sterilization of the product is required.

2.1.2 Sterilization

When compared to pasteurization, sterilization allows the total destruction of microorganisms present in the food product being processed. In fact, it is able to kill a wide range of microorganisms (yeasts, molds, bacteria), as well as spore formers, allowing thus the storage of the product posttreatment for a long time and at ambient temperature. Conventional sterilization con...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributors

- Preface

- Part A: Sustainable Food Production

- Part B: Sustainable Food Processing

- Part C: Sustainable Food Waste Management

- Index