eBook - ePub

Brewing Materials and Processes

A Practical Approach to Beer Excellence

- 366 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Brewing Materials and Processes

A Practical Approach to Beer Excellence

About this book

Brewing Materials and Processes: A Practical Approach to Beer Excellence presents a novel methodology on what goes into beer and the results of the process. From adjuncts to yeast, and from foam to chemometrics, this unique approach puts quality at its foundation, revealing how the right combination builds to a great beer. Based on years of both academic and industrial research and application, the book includes contributions from around the world with a shared focus on quality assurance and control.

Each chapter addresses the measurement tools and approaches available, along with the nature and significance of the specifications applied. In its entirety, the book represents a comprehensive description on how to address quality performance in brewing operations.

Understanding how the grain, hops, water, gases, worts, and other contributing elements establish the framework for quality is the core of ultimate quality achievement. The book is ideal for users in corporate R&D, researchers, students, highly-skilled small-scale brewers, and those seeking an understanding on how the parts impact the whole in beer production, providing them with an ideal companion to complement Beer: A Quality Perspective.

- Focuses on the practical approach to delivering beer quality, beginning with raw ingredients

- Includes an analytical perspective for each element, giving the reader insights into its role and impact on overall quality

- Provides a hands-on reference work for daily use

- Presents an essential volume in brewing education that addresses areas only lightly covered elsewhere

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Brewing Materials and Processes by Charles W Bamforth,Charles Bamforth,Charles W. Bamforth in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Food Science. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Malts

N. Davies Muntons, Stowmarket, United Kingdom

Abstract

The potential pitfalls of relying on a current malt specification to predict brewhouse performance have led to the development of many variants of the existing methods or wholly new tests; yet these have largely failed to become mainstream analyses. There is still significant confusion as to the differences in an analysis made using an Institute of Brewing or a European Brewery Convention (EBC) Congress mash. The old-style specification persists and it is essential that the user has a full understanding of what contributes to each analytical parameter, how they interact, the significance of analytical variance, and the linkage of genetics and the environment to the performance of malted barley. Malt specifications are being expanded to include metrics of sustainability requiring detailed carbon footprint of supply chain and process. Flavor and color assessment is now much more refined and can be exploited for product and process control and new product development.

Keywords

Analysis; Brew house performance; Carbon footprint analysis; Color; Flavor; Food safety; Innovation; Malt; SustainabilityIntroduction

Love it or loathe it, the traditional malt specification that has been with us for many years is likely to continue in use for the foreseeable future. Notwithstanding the universal acceptance that it is in parts flawed and difficult to interpret, it is still the mainstay of evaluating the suitability of malt for brewing. Over the years many suggestions for novel methods have been researched and suggested as either descriptors of malt quality or indicators of processability. So far, novel methods have had limited acceptance even when these have been extensively peer reviewed. Even with the new methods it can still be difficult to relate the results to brewhouse performance and cause problems when integrating them into a laboratory set up to follow recommended methods which are generally robust and which use recognized equipment and techniques rather than some of the intricacies involved in some newer assays. Familiarity and tradition have bolstered the conventional malt specification and will undoubtedly ensure it remains for some time yet.

What we have to contend with is that the concept of quality is often more perceptive than well defined. In other words, the judgment of the user based on his experience is not always easily and unequivocally traceable back to a specific analytical parameter (analyte). In many instances, one brewer or distiller describes a batch of malt as superb because it runs through his plant like “rocket fuel,” whereas another brewer finds the very same batch wholly unacceptable. The dilemma is how to resolve the root cause. Is it malt derived or process derived? Whatever the cause, a problem exists, but resolution may lie not with a fault in supply but rather in what has contributed to arriving at a material apparently in specification that could have been achieved in so many ways.

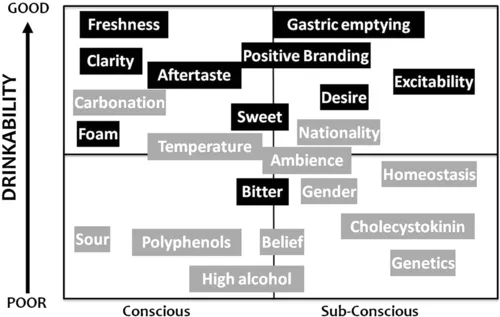

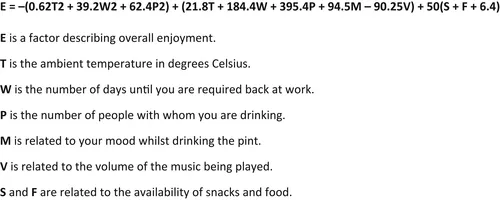

For consumers the link of malt analysis to product quality is not always appreciated. What malt parameters affect the enjoyment of the final product? Many factors have been found to influence drinkability and many could be attributable to malt (Davies, 2006a,b). We are aware of the influence of malt in beer either consciously or subconsciously and that affects our enjoyment of the product (Fig. 1.1). Precisely how biochemistry in malt manufacture affects some of the more curious aspects of the enjoyment of beer is largely unknown and cannot be reflected in the traditional malt specification. For a small handful of those parameters, however, there are clear links to malt. Freshness can be achieved with a malt that is low in factors that contribute to staling. Clarity can be impacted by malt modification and beta glucan level. Foam quality is affected by malt proteins and protein breakdown. Consumer preference is likely to be more influenced by marketing among the public. If a product is described as full of malt flavor and brewed from the finest malt and hops, it may be perceived as such, whereas a product brewed in the same way but advertised with flavors associated with fruits from esters will not be judged “malty”. The brewing and distilling trade has made a concerted effort to promote beer appreciation and wholesomeness of its raw materials, yet specific malt flavors or attributes still take a back seat in most sensory descriptions. In a slightly tongue in cheek attempt to describe how we enjoy beer, it has even been described mathematically. The controlling variables were beer temperature, number of people drinking, days before being back at work, venue mood, and availability of foods or snack, but with no place for the ingredients to contribute to that enjoyment (Fig. 1.2; Mindlab, 2012).

Figure 1.1 Factors associated with the drinkability of beer. Some factors we can consciously control and some are subconscious based on biochemistry and social or environmental factors. Arguably, the factors shaded in black are influenced by the malt component. Most of those factors can have a positive impact on the drinkability of beer. After Davies, N.L., November 2006a. Malt - a vital part of the brewer's palette, Monograph 34: E.B.C. Symposium, “Drinkability,” Edinburgh.

What Should a Malt Analysis Tell You?

Of course, this depends who is asking. For the breeder the difference could be as simple as whether the barley is suitable for feed or malting based on broad-brush measures such as hot-water extract, disease resistance, and good agronomy. For maltsters, a good variety would be one which performed well over a wide range of nitrogen (protein) contents and was easy to germinate and kiln. To a brewer often it is extract yield, color potential, clarity, and flavor. An overarching thread in all these requirements is that the best variety will reduce risk for the whole supply chain. Ideally, the breeder needs a variety that lasts up to 10 years to recoup breeding investment costs. Farmers need the certainty that a crop will grow well and be versatile in different seasonal weather conditions. Maltsters need varieties that can guarantee availability of good quality raw material free from disease and requiring the least processing utilities input. Brewers also need a secure supply of raw material and for the malt not to give rise to any negative processing or taint issues while providing good yeast nutrition and contributing to color and/or flavor. The concept of a risk premium to secure good quality malting barley at the right time is something very real in the modern malting supply chain. Risk can, of course, be managed and reduced for raw material availability, quality, and functional aspects of performance.

Figure 1.2 Formula to describe the enjoyment of beer. Nowhere does this equation allow for the product quality or taste. These parameters seem to be left to the brewer to control and are a given backdrop to enjoying the beverage. Although this is not a serious scientific formula, it illustrates an attitude to how alcoholic beverages are judged by the public. From Mindlab, 2012. Formula for the Perfect Pint. www.taylor-walker.co.uk/Media/Documents/PDF/news/WPR-Mindlab-The-Perfect-Pint.pdf.

For many years, breeders have used their extensive knowledge of plant phenotypes to determine those best for selection from crosses which may number 30,000 individual plants. In recent years, they have been aided through marker-assisted selection or genomics. In some cases it has been possible to link genetic sequences with specific barley or malt attributes and then to select or promote the effect of those sequences in new varieties. Markers based on single-nucleotide polymorphisms (SNPs) have rapidly gained popularity among breeders (Mammadov et al., 2012). There are, however, problems with this type of selection. A major hurdle is the highly repetitive nature of the plant genome (Meyers et al., 2001). The aim is to identify genes or quantitative trait loci (QTL) that contribute to a desired trait in the grain, with agronomy, or even in malt manufacture. Rather than generate a plethora of new QTL for scientific interest only, a recently concluded project sought to use the SNP/QTL libraries available around the world to enable breeding of specific desirable traits for malting barley into existing elite United Kingdom breeding varieties (Thomas et al., 2014; Ramsay et al., 2014). It was notable in the early stages of that research work that the major distinctions between barley varieties were associated with the vernalization gene. Unsurprisingly, we have spring and winter barley varieties as the major barley types. This is just one factor that makes selection of new varieties complex. The complex genetic interrelationships in barley make it difficult to relate process performance to such malt specification parameters as beta glucan, Kolbach index (KI), wort viscosity, fine–coarse extract difference, friability, and free-amino nitrogen (Wentz, 2000; Wentz et al., 2004). What is behind such difficulty in identifying how to breed and improve these characteristics? Many of the genetic traits are carried on different parts of the DNA sequence, on different chromosomes, and some genes exert multiple effects (pleiotropy). The result of this is that one gene or a series of linked genes may control a number of parameters on a malt specification, or that indeed some existing malt analytes are effectively redundant. Similar consequences have been found in attempting to relate diastatic power (DP) to improved fermentability (Evans et al., 2009)....

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- List of Contributors

- Preface

- Chapter 1. Malts

- Chapter 2. Adjuncts

- Chapter 3. Hops

- Chapter 4. Yeast

- Chapter 5. Water

- Chapter 6. Wort and Wort Quality Parameters

- Chapter 7. Alcohol and Its Measurement

- Chapter 8. Flavorsome Components of Beer

- Chapter 9. Dissolved Gases

- Chapter 10. Controlling Beer Foam and Gushing

- Chapter 11. Color

- Chapter 12. Haze Measurement

- Chapter 13. Sensory Analysis in the Brewery

- Chapter 14. Microbiology

- Appendix. Practicalities of Achieving Quality

- Index