- 384 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

The value of the groceries purchases in the USA is over $500 billion annually, most of which is accounted for by packaged foods. Plastic packaging of foods is not only ubiquitous in developed economies, but increasingly commonplace in the developing world, where plastic packaging is instrumental in decreasing the proportion of the food supply lost to spoilage.

This new handbook is a combination of new material and updated chapters, chosen by Dr. Sina Ebnesajjad, from recently published books on this subject. Plastic Films in Food Packaging offers a practical handbook for engineers, scientists and managers working in the food packaging industry, providing a tailor-made package of science and engineering fundamentals, best practice techniques and guidance on new and emerging technologies.

By covering materials, design, packaging processes, machinery and waste management together in one book, the authors enable the reader to take a lifecycle approach to food packaging.

The Handbook addresses questions related to film grades, types of packages for different types of foods, packaging technologies, machinery and waste management. Additionally the book provides a review of new and emerging technologies. Two chapters cover the development of barrier films for food packaging and the regulatory and safety aspects of food packaging.

- Essential information and practical guidance for engineers and scientists working at all stages of the food packaging lifecycle: from design through manufacture to recycling

- Includes key published material on plastic films in food packaging, updated specifically for this Handbook, and new material on the regulatory framework and safety aspects

- Coverage of materials and applications together in one handbook enables engineers and scientists to make informed design and manufacturing decisions

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription.

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes! You can use the Perlego app on both iOS or Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Yes, you can access Plastic Films in Food Packaging by Sina Ebnesajjad in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Food Science. We have over one million books available in our catalogue for you to explore.

Information

1

Introduction to Use of Plastics in Food Packaging

L.W. McKeen

Packaging film is very thin plastic and the basic component of plastic and elastomer materials is polymer. This chapter is narrowly focused on the commercial plastic films used in packaging. Generally, films are used as barriers; they keep dirt, germs, liquids or gases on one side of the film. Nearly any plastic can be made in film form, but this chapter will discuss only those that are used for packaging on a commercial basis. By definition, flexible packaging includes bags, envelopes, pouches, sachets, and wraps made of easily yielding materials such as film, foil, or paper sheeting which, when filled and sealed, acquires pliable shape. This chapter also will not cover multilayer films which are commercially very important but covered in another chapter.

Polymeric packaging materials are used to surround a package completely, securing its contents from gases and vapors, moisture, and biological effects of the outside environment, while providing a pleasing and often decorative appearance. Water vapor and atmospheric gases if allowed to permeate in or out of a package can alter the taste, color, and nutritional content of the packaged good. The effects of gas and vapors on food are complex and comprise a major branch of food science. The following is a brief overview. Additional details in terms of typical film properties and permeation properties are available in the literature (McKeen 2011, 2012).

1.1 Background

The global flexible packaging market is very large, as is shown in Table 1.1 for 2009. The table shows that polyethylenes and polypropylenes make up the bulk of the market. The six plastic types listed in the table account for over three quarters of the total packaging films produced. The growth rate is expected to be about 4% annually until 2016. Other key market drivers and trends identified for flexible packaging include:

• A trend toward conversion to biodegradable, sustainable, and recyclable flexible packaging materials to improve the environmental footprint of packaging.

• Flexible packaging films being made thinner to reduce costs and minimize waste after use, which also drives the need for higher performing materials.

• Flexible packaging products will replace bottles and containers for a range of food and beverage products.

Table 1.1

Global Flexible Packaging—2009

| Material | Millions of Tons (MMT) | % |

| Polyethylenes (PE) | 4.8 | 32.6 |

| Polypropylenes (PP) | 4.7 | 32 |

| Biaxial-orientated polyethylene terephthalate (BoPET) | 0.4 | 3 |

| Polyvinyl chloride (PVC) | 0.3 | 2.1 |

| Polyamide, nylon (PA) | 0.6 | 3.9 |

| Ethylene–vinyl alcohol (EVOH) | 0.4 | 2.6 |

| Total plastics | 11.3 | 76.2 |

| Paper, Aluminum foil, Cellulosics | 3.5 | 23.8 |

Source: PIRA International.

The following sections will look at the chemistry of various plastics used in flexible packaging films. The discussion will include chemical structures and where flexible films made of those materials are used.

1.2 Polyolefins

Polymers made from hydrocarbon monomers that contain a carbon–carbon double bond through which the polymer is made by addition polymerization are called polyolefins. An alkene, also called an olefin, is a chemical compound made of only carbon and hydrogen atoms containing at least one carbon-to-carbon double bond. The simplest alkenes, with only one double bond and no other functional groups, form a homologous series of hydrocarbons with the general formula CnH2n. The two simplest alkenes of this series are ethylene and propylene. When these are polymerized, they form polyethylene and polypropylene, which are the two of the plastics that account for the bulk of the plastic film packaging market. There are other specialty polyolefins that are made into very low-volume specialty films.

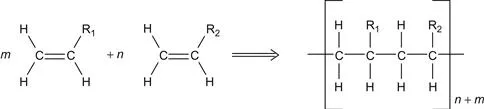

Polyolefins are made by addition polymerization (sometimes called chain-growth polymerization). A chain reaction adds new monomer units to the growing polymer molecule, one at a time through double bonds in the monomers. This is shown in Figure 1.1.

Figure 1.1 Addition polymerization.

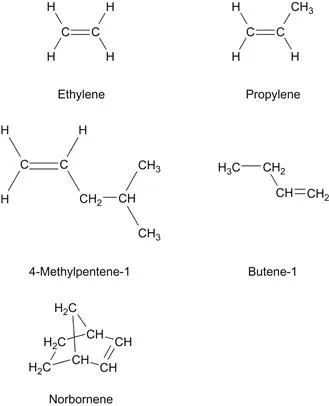

The structures of some of the monomers used to make polyethylene, polypropylene, and the other polyolefins discussed here are shown in Figure 1.2. Structures of the polymers may be found in the appropriate sections contain the data for those materials.

Figure 1.2 Chemical structures of the monomers used to make the polyolefins polyethylene, and polypropylene.

1.2.1 Polyethylene

The structure of polyethylene is given in Figure 1.1 where both R1 and R2 are replaced by H. There are several types of polyethylene, which are classified mostly by their density. There are several ASTM standards that are used to describe polyethylene including ASTM D2103—10 Standard Specification for Polyethylene Film and Sheeting. According to ASTM D1248—12 Standard Specification for Polyethylene Plastics Extrusion Materials for Wire and Cable, the basic types or classifications of polyethylene are as follows:

• Ultra low-density polyethylene (ULDPE), polymers with densities ranging from 0.890 to 0.905 g/cm3, contains comonomer.

• Very low-density polyethylene (VLDPE), polymers with densities ranging from 0.905 to 0.915 g/cm3, contains comonomer.

• Linear low-density polyethylene (LLDPE), polymers with densities ranging from 0.915 to 0.935 g/cm3, contains comonomer.

• Low-density polyethylene (LDPE), polymers with densities r...

Table of contents

- Cover image

- Title page

- Table of Contents

- Front-matter

- Copyright

- Preface

- 1. Introduction to Use of Plastics in Food Packaging

- 2. Polypropylene Films

- 3. PE-Based Multilayer Film Structures

- 4. Biaxially Oriented Films for Packaging Applications

- 5. Development of High-Barrier Film for Food Packaging

- 6. Applications of Polypropylene Films

- 7. Emerging Technologies in Food Packaging: Overview

- 8. Introduction to Active Food Packaging Technologies

- 9. Oxygen-Scavenging Packaging

- 10. Antimicrobial Packaging Systems

- 11. Damage Reduction to Food Products During Transportation and Handling

- 12. Food Packaging Machinery

- 13. Compostable Polymer Properties and Packaging Applications

- 14. Waste Management for Polymers in Food Packaging Industries

- 15. Polymer Blending for Packaging Applications

- 16. A Survey of Regulatory Aspects of Food Packaging

- Index