- 184 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

Extrusion is widely used for the preparation of a variety of foodstuffs including breakfast cereals, snack food and pasta, as well as pet food and animal and aquaculture feed. Extrusion problems solved provides responses to more than 300 frequently asked questions about the process of food extrusion and the techniques and equipment involved, in a practical question-and-answer format.The book is divided into twelve chapters for ease of reference: the opening chapters concentrate on introductory queries and on different components of an extruder system, followed by two chapters that help the reader select the correct type of extruder for a product. Chapters five and six discuss the impact of factors such as protein content and particle size on the extrusion process, while the use of pre-conditioners is discussed in chapter seven. The latter part of the book discusses specific types of extruder and die and knife assemblies, followed by a chapter on issues relating to drying extruded food products. The final chapter offers practical guidelines and rules of thumb for the most common issues relating to food and feed extrusion.Written by two leading experts in the field, Extrusion problems solved is an essential reference source and troubleshooting guide for professionals working in food, pet food and feed extrusion. It will also be a valuable training resource for students of extrusion.- Offers practical guidelines and rules of thumb for the most common food and feed extrusion problems- Chapters concentrate on introductory queries, types of extruder and components of extruder systems, knife assemblies, the use of pre-conditioners and issues in drying extruded food products- Provides responses to more than 300 frequently asked questions about the processes, equipment and techniques of food extrusion in a practical question-and-answer format

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

An introduction to food and feed extrusion and associated terminology

1 What is extrusion cooking?

2 What is cold extrusion?

3 What is dry extrusion?

4 What are the functions of a typical extruder?

5 What are the advantages of extrusion compared to other thermal processes?

6 What is the quality of the products produced by extrusion?

7 What is the waste stream from extrusion processing?

8 How easy is it to scale up the extrusion process?

9 Can I use extruders as continuous reactors?

10 Do extruders need to be shut down every day?

11 What is feedstock in extrusion?

12 What is a pellet?

13 What is the recipe or formulation?

14 What is the compression ratio?

15 What is L/D (length to diameter) ratio?

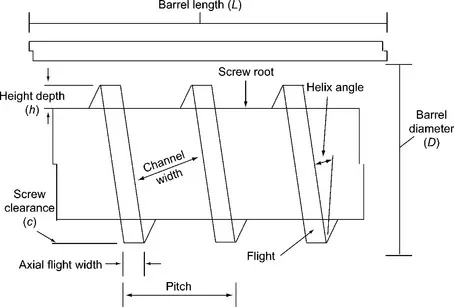

16 What is screw geometry?

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- About the authors

- Woodhead Publishing Series in Food Science, Technology and Nutrition

- Preface

- Sources of further information

- Chapter 1: An introduction to food and feed extrusion and associated terminology

- Chapter 2: Components of a food or feed extrusion system

- Chapter 3: Selecting the right type of extruder: single screw and twin screw extruders for food and feed production

- Chapter 4: Selecting the right type of extruder: dry extruders and expanders for food and feed production

- Chapter 5: Impact of protein, starch, fat and fiber on extruded foods and feeds

- Chapter 6: Impact of particle size and other ingredients on extruded foods and feeds

- Chapter 7: Preconditioners in food and feed extrusion: common problems and their solutions

- Chapter 8: Single screw extruders in food and feed extrusion: common problems and their solutions

- Chapter 9: Twin screw extruders in food and feed extrusion: common problems and their solutions

- Chapter 10: Die and knife assemblies in food and feed extrusion: common problems and their solutions

- Chapter 11: Drying extruded food products: common problems and their solutions

- Chapter 12: Practical considerations, rules of thumb and solutions to the most common problems in food and feed extrusion

- Index