Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry

- 448 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry

About this book

Handbook of Materials Failure Analysis: With Case Studies from the Oil and Gas Industry provides an updated understanding on why materials fail in specific situations, a vital element in developing and engineering new alternatives.This handbook covers analysis of materials failure in the oil and gas industry, where a single failed pipe can result in devastating consequences for people, wildlife, the environment, and the economy of a region.The book combines introductory sections on failure analysis with numerous real world case studies of pipelines and other types of materials failure in the oil and gas industry, including joint failure, leakage in crude oil storage tanks, failure of glass fibre reinforced epoxy pipes, and failure of stainless steel components in offshore platforms, amongst others.- Introduces readers to modern analytical techniques in materials failure analysis- Combines foundational knowledge with current research on the latest developments and innovations in the field- Includes numerous compelling case studies of materials failure in oil and gas pipelines and drilling platforms

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

Failure analysis of oil and gas transmission pipelines

Abstract

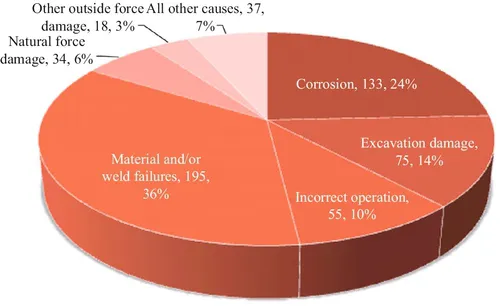

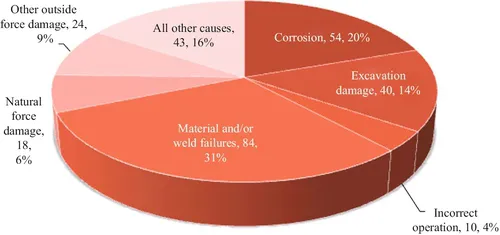

1 Introduction

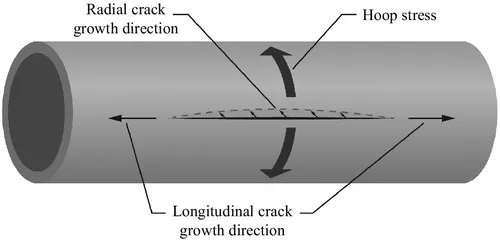

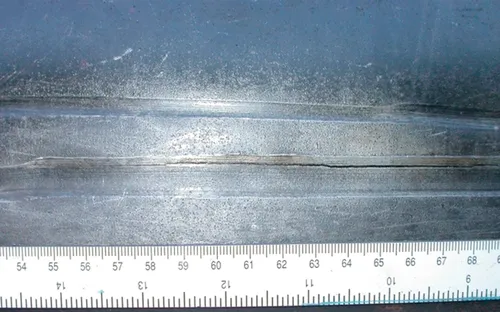

2 Mechanical Damage

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributors

- Preface

- Chapter 1: Failure analysis of oil and gas transmission pipelines

- Chapter 2: Modern analytical techniques in failure analysis of aerospace, chemical, and oil and gas industries

- Chapter 3: Methods for assessing defects leading to gas pipe failure

- Chapter 4: Failure of glass fiber-reinforced epoxy pipes in oil fields

- Chapter 5: Failures and integrity of pipelines subjected to soil movements

- Chapter 6: Oil field drill pipes failure

- Chapter 7: Failure analysis and solution studies on drill pipe thread gluing at the exit side of horizontal directional drilling

- Chapter 8: Causes and conditions for reamer blade balling during hole enlargement while drilling

- Chapter 9: Analysis of reamer failure based on vibration analysis of the rock breaking in horizontal directional drilling

- Chapter 10: Effect of artificial accelerated salt weathering on physical and mechanical behavior of sandstone samples from surface reservoirs

- Chapter 11: Stochastic failure analysis of defected oil and gas pipelines

- Chapter 12: Determining the cause of a carbon steel joint failure in a gas flow pipeline production facility

- Chapter 13: Experimental and numerical investigation of high-pressure water jetting effect toward NPS8 natural gas pipeline integrity—Establishing safety distance perimeter

- Chapter 14: Graphitization in pressure vessels and piping

- Chapter 15: Cases of failure analysis in petrochemical industry

- Chapter 16: Failure analysis of heat exchanger tubes in petrochemical industry: Microscopic analysis approach

- Chapter 17: Failure of 17-4 PH stainless steel components in offshore platforms

- Chapter 18: Fracture representation and assessment for tubular offshore structures

- Chapter 19: Manufacturing, testing, and operational techniques to prevent sour service damages

- Chapter 20: The role of microfractography in failure analysis of machine components and structures

- Index