- 760 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Handbook of Farm, Dairy and Food Machinery Engineering

About this book

Handbook of Farm, Dairy and Food Machinery Engineering is the essential reference for engineers who need to understand those aspects of the food industry from farm machinery to food storage facilities to the machinery that processes and packages our foods.The process of getting food from "farm to fork, " as the saying goes, involves more than planting, harvesting, shipping, processing, packaging and distributing—though those are all key components. Effective and efficient food delivery systems are built around processes that maximize the effort while minimizing cost, time, and resource depletion.This comprehensive reference is for engineers who design and build machinery and processing equipment, shipping containers, and packaging and storage equipment. It includes cutting-edge coverage of microwave vacuum application in grain processing, cacao processing, fruit and vegetable processing, ohmic heating of meat, facility design, closures for glass containers, double seaming, and much more.- Provides cross-topic information for translational research and potential application- Focuses on design and controls – written for engineers by engineers – always with practical applications in mind- Includes design of machinery and facilities as well as theoretical basis for determining and predicting behavior of foods as they are handled and processed

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app.

Information

The Food Engineer

1 Nature of Work and Necessary Skills

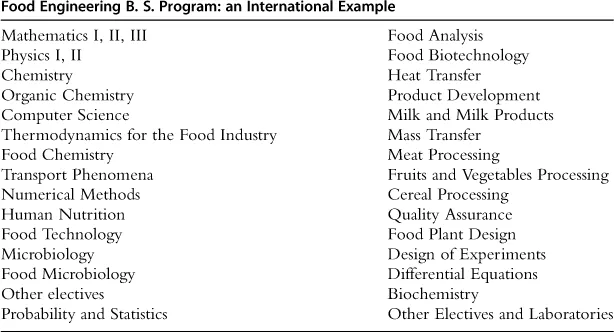

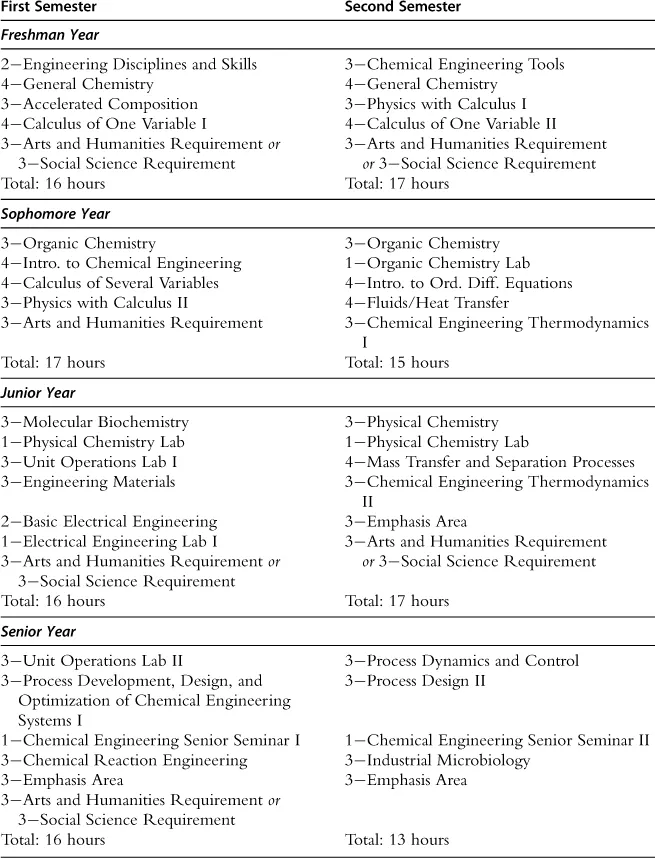

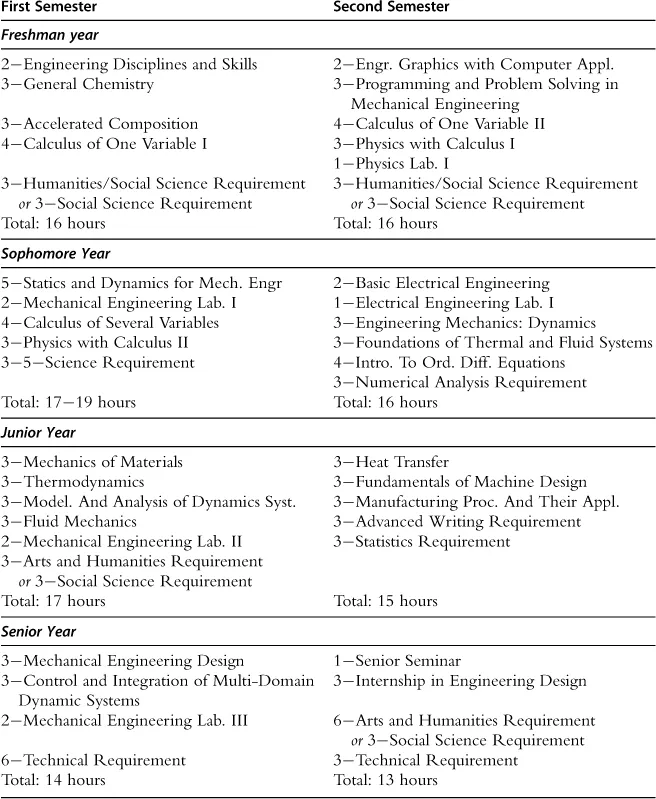

2 Academic and Industry Preparation

3 Work Opportunities for a Food Engineer

3.1 Job Description Sample 1

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Preface to the Second Edition

- Preface to the First Edition

- List of Contributors

- Chapter 1. The Food Engineer

- Chapter 2. Food Regulations

- Chapter 3. Food Safety Engineering

- Chapter 4. Farm Machinery Automation for Tillage, Planting Cultivation, and Harvesting

- Chapter 5. Air Seeders for Conservation Tillage Crop Production

- Chapter 6. Grain Harvesting Machinery

- Chapter 7. Grain Storage Systems Design

- Chapter 8. Milking Machines and Milking Parlors

- Chapter 9. Dairy Product Processing Equipment

- Chapter 10. Grain Process Engineering

- Chapter 11. Technology of Processing of Horticultural Crops

- Chapter 12. Food Drying and Evaporation Processing Operations

- Chapter 13. Food Freezing Technology

- Chapter 14. Heat and Mass Transfer in Food Processing

- Chapter 15. Food Rheology

- Chapter 16. Food Extruders

- Chapter 17. Thermal Processing for Food Sterilization and Preservation

- Chapter 18. Artificial Neural Network (ANN) Based Process Modeling

- Chapter 19. Design of Food Process Controls Systems

- Chapter 20. Ohmic Pasteurization of Meat and Meat Products

- Chapter 21. Food Processing Facility Design

- Chapter 22. Sanitary Pump Selection and Use

- Chapter 23. Agricultural Waste Management in Food Processing

- Chapter 24. Food Packaging Machinery

- Chapter 25. Damage Reduction to Food Products During Transportation and Handling

- Index