1.1 General Reasons for Processing

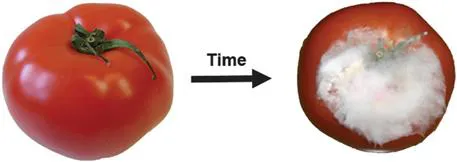

At first glance, the reasons why food is processed may seem obvious to some. It is often considered that food products are processed solely to extend their storage life or to reduce the risk of spoilage (Figure 1.1). However, there are additional reasons why foods are processed.

Figure 1.1 Avoiding microbial spoilage is a major reason foods are processed.

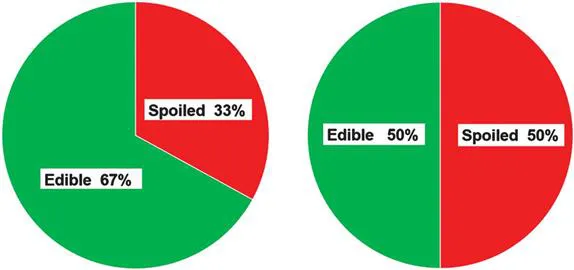

It has been estimated by various sources that one-third to one-half of the world's food supply is lost due to spoilage (Figure 1.2). Food losses in the United States of America have been estimated to be as high as 40% (Gunders, 2012).

Figure 1.2 One-third to one-half of the world's food supply is lost due to spoilage.

Essentially, the quest to extend the storage life or “shelf-life” of a food product stems from a need to match supplies of food with the demands of time and space, or location.

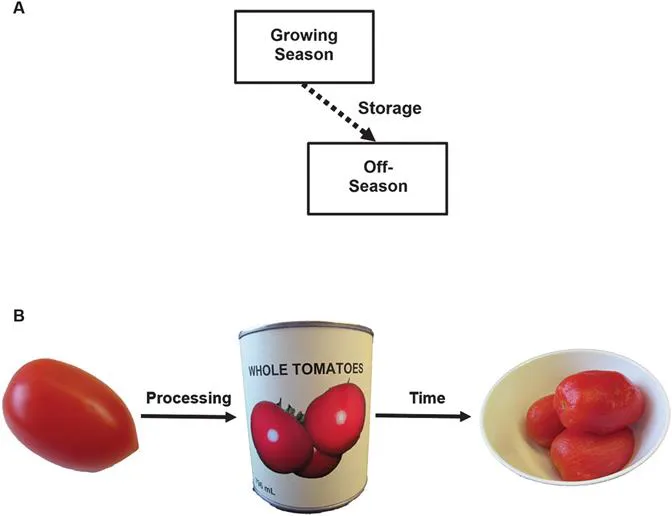

In countries like Canada and the northern portions of the United States, the ability to grow food products is limited by the climatic conditions characterized by the four seasons of the year. During an appreciable portion of the year, it is too cold to grow crops. This means that crops harvested in the late summer or early fall must be maintained in a quality form for use throughout the winter and spring months until fresh produce can be obtained during the following year's growing season. Food processing allows these time-related needs to be addressed.

Apart from the growing season considerations, many consumers want foods that will simply last for a long time when stored in their pantries, on their kitchen shelves, or in their freezers. By processing foods such as fruits and vegetables when they are at their peak of quality and freshness, food processors can deliver products to meet these demands (Figure 1.3).

Figure 1.3 (A) Processing permits use of foods in the off-season, (B) Processing extends product shelf-life.

While certain areas of the world are enduring months of harsh climates, other portions of the world are enjoying much more temperate conditions. These countries may be able to harvest crops continuously, or may be able to grow two crops per year.

By exporting agricultural commodities, many tropical countries are able to sell their produce to an enthusiastic market willing to pay higher prices for fresh produce during the “off season”.

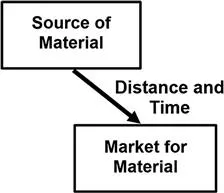

Food processing often plays a role in getting this food from one location to another while minimizing the loss of quality and nutrition, thereby addressing what we might describe as “space-related needs” (Figure 1.4).

Figure 1.4 Processing permits transportation of food materials over distances and time.

Many of the things that are taken for granted during the winter months, including fresh tropical fruits, were not available prior to the end of World War II. It was not until controlled supply chains were developed to get these products from their sources to waiting markets that the potential for exports could be fully exploited.

Unfortunately, there are areas of the world that cannot produce enough food to feed their own populations during any portion of the year. Through drought or the encroachment of desert landscapes, there is not the water nor the soil fertility to produce sufficient amounts of food. At the same time, more distant nations may be enjoying bumper harvests and actually be experiencing food surpluses that go well beyond their foreseeable future needs. If these foods could be shipped to the areas in such dire distress, in a readily utilizable form that would be stable over time, both the spatial and time-related needs could be met. Fortunately, this is within the realm of possibility through the application of food processing technology.

Food processing also helps to ensure the cleanliness and safety of the world's food supply. Through the application of food processing, it is possible to reduce levels of microbial contamination that would otherwise create outbreaks of disease that could afflict millions.

Simply washing fruits and vegetables in clean, “potable” (i.e., drinkable) water is a good first step in any processing procedure (Figure 1.5).

Figure 1.5 Washing is an important first step in processing.

Non-microbial contaminants and undesirable foreign materials are also routinely removed during processing (Figure 1.6).

Figure 1.6 Small stones and pieces of metal can find their way into raw material supplies.

Food that would otherwise spoil before it could even get to market is maintained in an edible form by minimal processing techniques that have little, if any, effect on the food itself.

Although many of us never really think about it, processing makes some foods edible that otherwise could not be digested in the human body. Examples of this include starch-based foods such as Irish potatoes. In their raw form, potatoes contain ungelatinized (granular) starches which humans cannot readily digest. However, by heating the potatoes in boiling water (or by other means), these starches are gelatinized. The gelatinized starches can then be digested (Figure 1.7).

Figure 1.7 Starches found in Irish potatoes must be gelatinized for digestibility.

Through food processing, consumers can experience variety, convenience, and diversity in their diets that was not possible in the past. Food science has provided flavours and forms of food that are convenient to use while meeting the expected quality levels of the consumer.

Time-impoverished families want, and can get, complete meals that are essentially ready to serve with little or next to no preparation. Store shelves and freezer compartments are lined with literally hundreds of products to satisfy the needs of families who no longer have the time to prepare a traditional sit-down dinner meal.

Instantized potato flakes (Figure 1.8) are available that reduce the time for preparing mashed boiled potatoes to a matter of minutes. This is in contrast to the time taken to peel the potatoes, cut them, boil them in water until fully gelatinized, and mash them for final use. With instantized potato flakes, the appropriate volume of flakes is mixed with the prescribed volumes of boiling water and milk. After mixing, the potatoes are ready to serve.

Figure 1.8 Instantized potato flakes are a convenient alternative to using raw potatoes.

Microwavable meals or ready-to-eat meals from in-store delicatessens cater to these individuals and families (Figure 1.9).

Figure 1.9 Microwavable meals offer variety and convenience (frozen on left, heated on right).

A diversity of ethnic dishes that was unknown to preceding generations can now be enjoyed by today's consumer. As communications, world travel, and immigration have increased, so has the appreciation of the fine foods that are available in what were previously considered to be exotic locations. Food processing has brought the production of many “ethnic” foods to countries where they have now become favourites. Not only that, but they are available in convenient formats which may only require thawing and heating.