![]()

GROWN

Welcome to the wondrous world of grown materials: fish leather, textiles created from bacteria and horsehair, plastic made from chicken feathers, and the more usual grown materials such as plant fibres and wood. This section is one of the major emerging materials families, an area that encompasses both the big chemical industries – who are looking into extracting proteins from starch to make new types of plastic – as well as research projects from individuals like Fiorenzo Omenetto, a scientist who is developing an incredible array of uses for silk.

This section includes experimental projects based on byproducts of natural waste which are deconstructed to make new types of materials. The urgent need to find rapidly renewable materials is driving designers to experiment with waste materials, for example Erik De Laurens is making a new composite from fish scales, and the rapidly renewable and biodegradable mycelium (grown from the roots of mushrooms in a matter of days) is being used to replace expanded polystyrene.

If, as the introduction to this book points out, one of the key drivers for materials development is the need to find more sustainable materials, then most of these innovations can be found in this section. The last century will be remembered as a time when classical notions of production were blown apart by plastics derived from oil. The next century might see a time when our plastics and products don’t come from machines but are grown. Graze across the crunchy textures, playful interactions, natural patterns and interesting surfaces of materials that are currently being developed.

![]()

Red Cedar (Juniperus spp.)

As a schoolboy lacking in concentration, I found something incredibly therapeutic about sharpening a pencil. Whether it’s with an old fashioned magnesium sharpener or a razor-edged steel craft knife, there is no mistaking the peppery smell of that sharpened pencil and, for some, the irresistible urge to gnaw on the end of one. As an object made of wood it is one that has a direct immediacy with its user. You hold it, digging your nail into its plastic-painted surface, smell it, carve it into a needle sharp point, and chew it. Through its built-in obsolescence it goes from being an object of satisfying proportions to a redundant little stump. For this once young schoolboy it also evokes memories of a material and product that empowered me to express my early designs for intergalactic space ships.

One of the reasons that the pencil provokes such strong associations is due to its aromatic smell, which comes from the use of red cedar, a timber with a reddish-brown heartwood and a smooth, fine grain. Since the first mass-produced pencils were developed in Germany in the seventeenth century they have continued to evolve into a product of high mass production. One of the curious facts about pencils is that 75 per cent of pencils sold in the US are yellow, which apparently is due to an old standard established in the nineteenth century, where yellow was used as a symbol of prestige.

Image: Cedar pencil

Key features

•Medium density: 380 kg/m3 (23 lbs/ft3)

•Straight, fine, even grain

•Aromatic scent

•Low stiffness

•Not suited to steam bending

Sources

Mainly Eastern USA and Canada, Uganda, Kenya and Tanzania.

Cost

The most common type of cedar is the western red variety. It is moderately priced and can easily be found on the market.

Sustainability issues

According to the IUCN (International Union for Conservation of Nature) red cedar is one of the least threatened trees.

Production

Pencil cedar can be worked easily with both hand and machine tools with little blunting effect on blades. It will tend to split if nailed and has poor steam-bending properties.

Typical applications

The aroma of cedar has been put to use for products such as cigar boxes, wardrobes and chests – to ward away moths – coffins and furniture veneers. Waste shavings from production are often distilled for use in essential oils.

| + | – |

| –Easy to work –Aromatic scent –Straight, even grain –Sustainable | –Prone to splitting –Poor steam bending |

![]()

Pine (Pinus sylvestris)

The name pine suggests scented temperate forest, but it’s impossible to describe pine as a specific wood, because it’s actually a family of woods, which includes trees with evocative names such as sugar pine and Table Mountain pine, as well as the perhaps more well known Scots pine, spruce pine and yellow pine. Its timber ranges from a gummy, resinous wood to a warm toasted blonde pine, with a white sapwood and a heartwood varying from light yellow-brown to reddish brown, often with a faint scent of resin.

Pines are one of the most widely recognized and used timbers, chosen mainly for their good range of structural properties, including strength, stiffness, good workability, excellent stability and low shrinkage. Due to the fact that its growth range varies from hot to cold climates, the weight of pines greatly varies. Although pine is itself a family it is also part of a larger group that, together with spruce and larch, is known under the collective name of ‘deal’, a term used to describe coniferous softwoods.

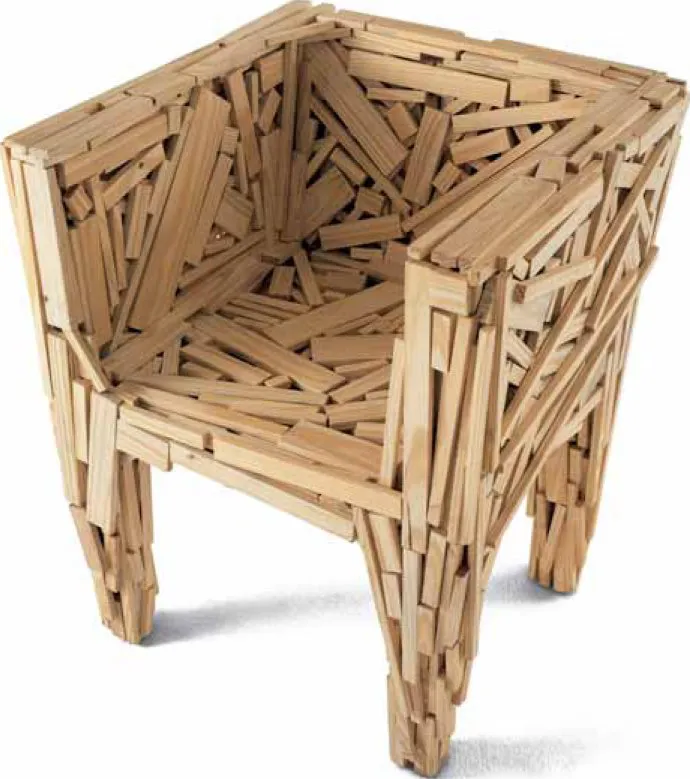

Apart from scented forests, the other association of pine is its ‘country kitchen’ aesthetic, which seemed to dominate European kitchen design for a large part of the late twentieth century. In contrast, what I like about the Favela armchair by Fernando and Humberto Campana is the adhoc nature of the design and construction, something that seems appropriate for a timber with so many diverse applications.

Image: Favela chair, Fernando + Humberto Campana

Key features

•390-690 kg/m3 (24-43 lbs/ft3) Straight even grain

•Easy to work

•Finishes well

•Low shrinkage

•Low strength

Sources

Mainly Canada and the USA, UK, mainland Europe and the Scandinavian countries; however, pine grows in countries as far south as Portugal and as far north as Siberia. The colder the climate, the slower the growth and the better the quality.

Cost

Most pines are generally moderately priced.

Sustainability issues

Pines are a fast growing tree and so can be seen as renewable under the correct forestry stewardship. One of the interesting aspects of pine trees in relation to their growth is that they are often planted next to ‘nurse’ oak trees, which protect the pine saplings from wind while allowing sunlight to penetrate.

Production

Pines are generally easy to work; however, the sticky resin in some pines can be problematic. Dead knots can also give problems by dropping out. They glue well unless the piece of wood is particularly resinous. They also accept stains, paints, oil and lacquers well.

Typical applications

The excellent stability of pine makes it particularly suitable for pattern making, doors and drawing boards. It is also used for light and medium construction, boat building, joinery and furniture making and telegraph poles. Like Maple, pines are also valued for their by-products. The resin secreted by pines has a large number of uses that include resin, tar and turpentine.

| + | – |

| –Easy to work –Good dimensional stability –Accepts finishes well –Sustainable | –Not especially strong –Dead knots can drop out of the wood |

![]()

Douglas Fir (Pseudotsuga menziesii)

Plastic will always be plastic. Of course, each type of this vast family is different but if one creates a grade of polypropylene then, without fail, it will always be the same, no matter how many different products you make from it. However, the biography for many grown materials is a chronicle of sustained weather and geography. Unlike wine, a product so distinctly affected by nature, where the history of the grape is reflected in its taste, the history of wood affects the way it functions and looks, with the grain storing the memories of time and of place.

For me, there is nothing like the distinctive, unpretentious markings of Douglas fir. Douglas fir is perhaps not as recognized and well known as other softwood timbers, such as pine or cedar, but it does have wonderful colouring and grain. In terms of colouring, it has a warm honey colour with rich, wide reddish-brown bands of heartwood, which are contrasted by early and late wood. This colouring, combined with wonderful, wavy tiger-like markings, and its rich, sweet and spicy scent set it apart from other softwoods. Also known as British Columbian pine, Columbian pine, Douglas fir, red and yellow fir and Oregon pine it stands alone as its own species and is not a pine.

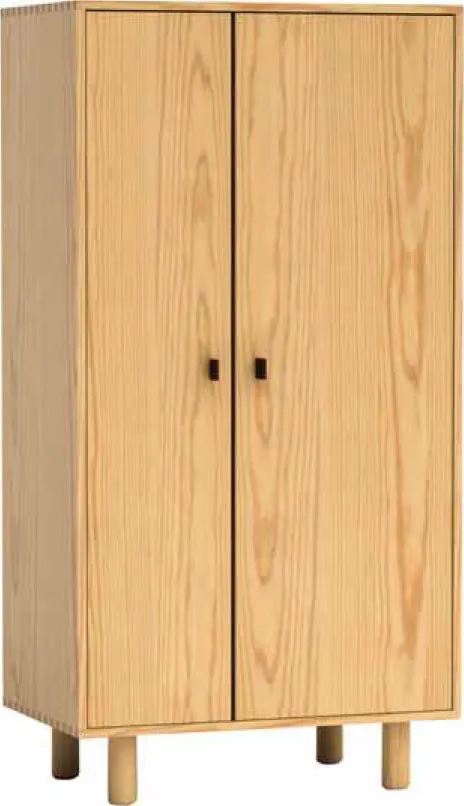

Image: Crate Wardrobe by Jasper Morrison

Key features

•530 kg/m3 (33 lbs/ft...