- 288 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About this book

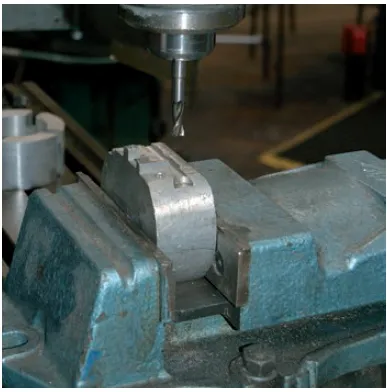

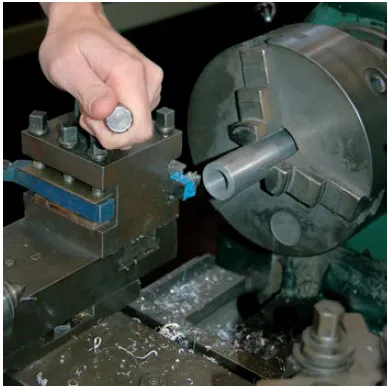

There are many ways in which a product can be manufactured but most designers know only a handful of techniques. Both informative and incredibly easy to use, this bestselling book explains over 100 production methods in detail. With specially commissioned diagrams, case studies and step-by-step photographs of the manufacturing process, Making It uses contemporary design as a vehicle to describe production processes. It lists their pros and cons, suitable production volumes, costs involved, speed of production, relevant materials and typical applications. The new edition of this inspirational book also evaluates each process in terms of sustainability and its effects on the environment.Making It appeals not only to product designers but also to interior designers, furniture and graphic designers who need access to a range of production methods, as well as to all students of design. The expanded edition includes nine new processes and an all-new section of 40 finishing techniques.

Trusted by 375,005 students

Access to over 1 million titles for a fair monthly price.

Study more efficiently using our study tools.

Information

Cut from Solid

Product | Mini Maglite® torch |

Designer | Anthony Maglica |

Materials | aluminum |

Manufacturer | Maglite Instruments Inc. |

Country | USA |

Date | 1979 |

Table of contents

- Cover

- Title Page

- Copyright

- Contents

- Introduction

- Comparing Processes

- 1. Cut from Solid

- 2. Sheet

- 3. Continuous

- 4. Thin & Hollow

- 5. Into Solid

- 6. Complex

- 7. Advanced

- 8. Finishing Techniques

- Glossary

- Index

- Acknowledgments

- Picture Credits

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app