Multiphysics Simulation by Design for Electrical Machines, Power Electronics and Drives

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Multiphysics Simulation by Design for Electrical Machines, Power Electronics and Drives

About this book

Presents applied theory and advanced simulation techniques for electric machines and drives

This book combines the knowledge of experts from both academia and the software industry to present theories of multiphysics simulation by design for electrical machines, power electronics, and drives. The comprehensive design approach described within supports new applications required by technologies sustaining high drive efficiency. The highlighted framework considers the electric machine at the heart of the entire electric drive. The book also emphasizes the simulation by design concept—a concept that frames the entire highlighted design methodology, which is described and illustrated by various advanced simulation technologies.

Multiphysics Simulation by Design for Electrical Machines, Power Electronics and Drives begins with the basics of electrical machine design and manufacturing tolerances. It also discusses fundamental aspects of the state of the art design process and includes examples from industrial practice. It explains FEM-based analysis techniques for electrical machine design—providing details on how it can be employed in ANSYS Maxwell software. In addition, the book covers advanced magnetic material modeling capabilities employed in numerical computation; thermal analysis; automated optimization for electric machines; and power electronics and drive systems. This valuable resource:

- Delivers the multi-physics know-how based on practical electric machine design methodologies

- Provides an extensive overview of electric machine design optimization and its integration with power electronics and drives

- Incorporates case studies from industrial practice and research and development projects

Multiphysics Simulation by Design for Electrical Machines, Power Electronics and Drives is an incredibly helpful book for design engineers, application and system engineers, and technical professionals. It will also benefit graduate engineering students with a strong interest in electric machines and drives.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

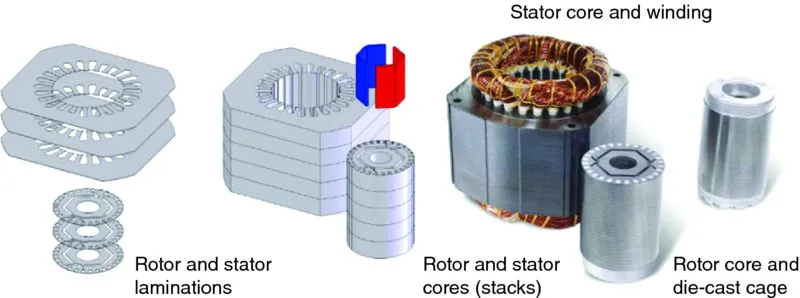

Basics of Electrical Machines Design and Manufacturing Tolerances

1.1 Introduction

![Diagram shows stator modular construction example with segmented core and concentrated coils which form multiphase winding [2, 3].](https://book-extracts.perlego.com/992205/images/ec01f002-plgo-compressed.webp)

Table of contents

- Cover

- IEEE Press

- Title page

- Copyright

- Acknowledgments

- Preface

- CHAPTER 1 Basics of Electrical Machines Design and Manufacturing Tolerances

- CHAPTER 2 Fem-Based Analysis Techniques for Electrical Machine Design

- CHAPTER 3 Magnetic Material Modeling

- CHAPTER 4 Thermal Problems in Electrical Machines

- CHAPTER 5 Automated Optimization for Electric Machines

- CHAPTER 6 Power Electronics and Drive Systems

- Index

- IEEE Press Series on Power Engineering

- EULA

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app