Introduction to Plant Automation and Controls

Raymond F. Gardner

- 544 Seiten

- English

- ePUB (handyfreundlich)

- Über iOS und Android verfügbar

Introduction to Plant Automation and Controls

Raymond F. Gardner

Über dieses Buch

Introduction to Plant Automation and Controls addresses all aspects of modern central plant control systems, including instrumentation, control theory, plant systems, VFDs, PLCs, and supervisory systems. Design concepts and operational behavior of various plants are linked to their control philosophies in a manner that helps new or experienced engineers understand the process behind controls, installation, programming, and troubleshooting of automated systems.

This groundbreaking book ties modern electronic-based automation and control systems to the special needs of plants and equipment. It applies practical plant operating experience, electronic-equipment design, and plant engineering to bring a unique approach to aspects of plant controls including security, programming languages, and digital theory. The multidimensional content, supported with 500 illustrations, ties together all aspects of plant controls into a single-source reference of otherwise difficult-to-find information.

The increasing complexity of plant control systems requires engineers who can relate plant operations and behaviors to their control requirements. This book is ideal for readers with limited electrical and electronic experience, particularly those looking for a multidisciplinary approach for obtaining a practical understanding of control systems related to the best operating practices of large or small plants. It is an invaluable resource for becoming an expert in this field or as a single-source reference for plant control systems.

Author

Raymond F. Gardner is a professor of engineering at the U.S. Merchant Marine Academy at Kings Point, New York, and has been a practicing engineer for more than 40 years.

Häufig gestellte Fragen

Information

Chapter 1

Measurement fundamentals and instrumentation

INSTRUMENTATION DEFINITIONS

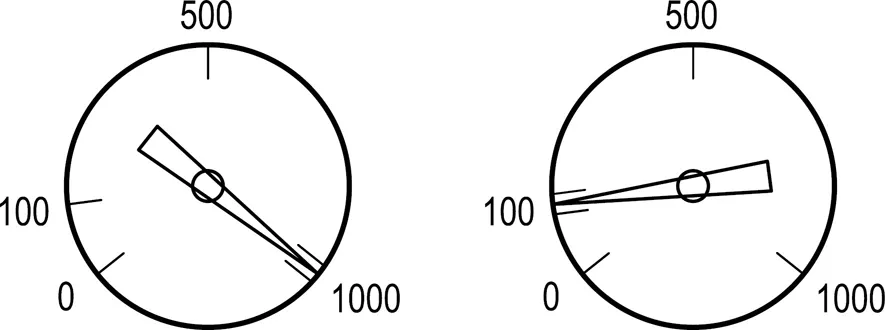

GAGE ACCURACY