1.1 Introduction

Magnesium and its alloys have a high strength/density ratio and have found many successful applications, particularly in the automotive and aerospace industries (Song, 2005b, 2006; Makar and Kruger, 1993; Aghion and Bronfin, 2000; Polmear, 1996; Bettles et al., 2003a and b). However, the poor corrosion resistance of existing magnesium alloys in some service environments has limited the further expansion of their application. Existing investigations have clearly suggested that the corrosion of Mg alloys is unusual in terms of their corrosion behavior (Song, 2004a, 2005b, 2006, 2009a, 2009c; Song and Atrens, 2007; Winzer et al., 2005, 2007, 2008; Wan et al., 2006; Wang et al., 2007). For more successful application of Mg alloys, it is important to understand their characteristic corrosion phenomena. This chapter systematically summarizes the corrosion characteristics of Mg alloys in order to better understand their corrosion performance. Based on this, a potential strategy is proposed to mitigate their corrosion.

1.2 Corrosion behavior of magnesium (Mg) alloys

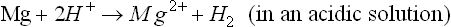

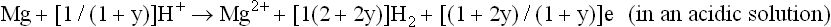

Mg alloys follow a corrosion mechanism different from other engineering metallic materials such as steel, aluminum alloys, and zinc. on pure Mg or a Mg alloy, it is well known that the overall corrosion reaction can be written as (Makar and Kruger, 1993; Song and Atrens, 1999; Song, 2005b, 2006):

or

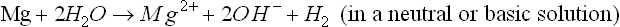

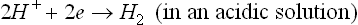

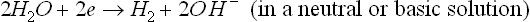

This overall corrosion can be decomposed into anodic and cathodic reactions. The cathodic process is (Song, 2005b, 2006):

or

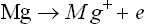

and the anodic process (Song, 2005b, 2006):

where y is the ratio of Mg + turning into Mg2 + over reacting with H2O to produce H2.

The detailed anodic and cathodic reactions under a steady corrosion condition have been illustrated previously (Song et al., 1997a, 1997b; Song, 2005b; Song and Atrens, 1999, 2003). In general, the anodic dissolution occurs mainly in a film-free area, while in a film covered area the anodic dissolution is negligible. The cathodic reaction, which is mainly a hydrogen evolution process, can take place in both film-free and film-covered areas, but the reaction rate in a film-free area is much faster than the rate in a film-covered area, particularly if impurity particles are present there.

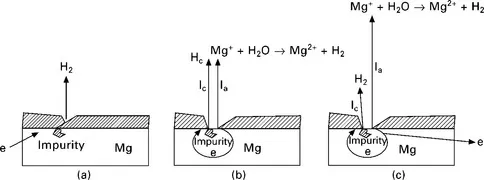

If Mg is cathodically polarized to a very negative potential, Mg is fully covered by a thin film and there is no film-free area. Thus, the anodic dissolution of magnesium is very low, almost zero. However, the cathodic hydrogen evolution can still occur on the thin film surface at such a negative potential. The hydrogen evolution rate will decrease as the polarization potential becomes more positive until a critical potential Ept is reached. At Ept, the surface film starts to break down and both the hydrogen evolution and the Mg anodic dissolution become easier. The dissolution of Mg produces intermediate Mg+ which subsequently leads to generation of hydrogen. In other words, there are two mechanisms of hydrogen evolution; one is a normal cathodic hydrogen evolution process driven by negative polarization potentials, and the other is a magnesium dissolution induced reaction. The process is schematically illustrated in Fig. 1.1.

1.1 Electrochemical corrosion and negative difference effect on the magnesium surface (Song, 2005a): (a) at a very negative cathodic potential; (b) at the critical potential Ept; (c) at a potential more positive than Ept.

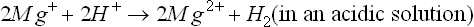

The reactions involved in the process are as follows:

then:

or

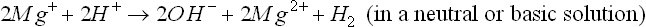

The anodic dissolution rate of Mg (Eq. 1.7) increases as the polarization potential or current becomes more positive. This produces additional hydrogen at a more positive potential via the reactions in Equations 1.8 or 1.9. The hydrogen evolution occurring in a corroding (film-free) area is termed ‘anodic hydrogen evolution’ (AHE), because it is closely associated with the anodic dissolution process. One important aspect is that it becomes faster as the anodic polarization potential becomes more positive, as if it were an anodic process (see Fig. 1.2). This differs from the normal cathodic hydrogen evolution (CHE) in that hydrogen evolution can occur on either the film-free or the film-covered areas, and decreases with positively shifting polarization potential in the cathodic region (see Fig. 1.2).

1.2 Hydrogen evolution and Mg dissolution rates: (a) Mg in 1N NaCI (pH 11) (Song et al., 1997b); (b) Mg in 1N Na2SO4 (pH 11) (Song et al., 1997a); (c) AZ21 (matrix phase) in 1N NaCl (pH 11) (Song, 2005b); (d) AZ91 ingot in 1N NaCl (pH 11) (Song, 2005b); (e) diecast AZ91 in 1N NaCl (pH 11) (Song, 2005b); (f) sand cast MEZ in 5 wt% NaCl (Song, 2005b).

1.2.1 Hydrogen evolution

The overall corrosion Equations 1.1. or 1.2 suggest that the dissolution of Mg is always accompanied by hydrogen evolution. This corrosion-related hydrogen evolution is also applicable to Mg alloys in aqueous solutions (Song et al., 1998, 2001, 2005a; Song and Atrens, 1998, 2003; Song and St John, 2002), including engine coolants (Song and St John, 2004, 2005) and simulated body fluids (SBF) (Song and Song, 2006, 2007; Song, 2007b). In a severe corrosion process, Mg particle undermining (Mg particles falling into solution due to the surrounding material being completely corroded) may take place.

However, this process has been shown to have no influence upon either of the reactions in Equations 1.1 or 1.2 (Song et al., 1997b). Therefore, for Mg and Mg alloys in an aqueous solution, the hydrogen evolution phenomenon, which includes cathodic hydrogen evolution (CHE) and ‘anodic hydrogen evolution’ (ACE), is one of the most important features.

Having realized that the hydrogen evolution is closely associated with the corrosion of Mg and its alloys, a simple hydrogen evolution measurement technique was first employed by Song et al. (1997b) to estimate the corrosion rate of Mg. After further illustration of the theory and analysis of possible errors inherent to this method (Song, 2005b, 2006; Song et al., 2001), it has also been widely used on many Mg alloys (Song, 2005a; Song and St John, 2002; Hallope...