eBook - ePub

Stainless Steel 2000

Thermochemical Surface Engineering of Stainless Steel

Tom Bell, Katsuya Akamatsu, Tom Bell, Katsuya Akamatsu

This is a test

Partager le livre

- 448 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

eBook - ePub

Stainless Steel 2000

Thermochemical Surface Engineering of Stainless Steel

Tom Bell, Katsuya Akamatsu, Tom Bell, Katsuya Akamatsu

Détails du livre

Aperçu du livre

Table des matières

Citations

À propos de ce livre

Austenitic stainless steels lend themselves to a wide range of applications. However, they normally stiffer from poor wear resistance and do not respond well to traditional surface treatments. This volume. the fruit of a current status seminar, reflects the enormous strides which have been made in the last few years in the study of the expanded austenite phase (also called the S phase) and the development of new surface treatment techniques. As well as the papers presented at the seminar, the book contains selection from related papers and a comprehensive bibliography of the literature on the subject from 1979 to 2000.

Foire aux questions

Comment puis-je résilier mon abonnement ?

Il vous suffit de vous rendre dans la section compte dans paramètres et de cliquer sur « Résilier l’abonnement ». C’est aussi simple que cela ! Une fois que vous aurez résilié votre abonnement, il restera actif pour le reste de la période pour laquelle vous avez payé. Découvrez-en plus ici.

Puis-je / comment puis-je télécharger des livres ?

Pour le moment, tous nos livres en format ePub adaptés aux mobiles peuvent être téléchargés via l’application. La plupart de nos PDF sont également disponibles en téléchargement et les autres seront téléchargeables très prochainement. Découvrez-en plus ici.

Quelle est la différence entre les formules tarifaires ?

Les deux abonnements vous donnent un accès complet à la bibliothèque et à toutes les fonctionnalités de Perlego. Les seules différences sont les tarifs ainsi que la période d’abonnement : avec l’abonnement annuel, vous économiserez environ 30 % par rapport à 12 mois d’abonnement mensuel.

Qu’est-ce que Perlego ?

Nous sommes un service d’abonnement à des ouvrages universitaires en ligne, où vous pouvez accéder à toute une bibliothèque pour un prix inférieur à celui d’un seul livre par mois. Avec plus d’un million de livres sur plus de 1 000 sujets, nous avons ce qu’il vous faut ! Découvrez-en plus ici.

Prenez-vous en charge la synthèse vocale ?

Recherchez le symbole Écouter sur votre prochain livre pour voir si vous pouvez l’écouter. L’outil Écouter lit le texte à haute voix pour vous, en surlignant le passage qui est en cours de lecture. Vous pouvez le mettre sur pause, l’accélérer ou le ralentir. Découvrez-en plus ici.

Est-ce que Stainless Steel 2000 est un PDF/ePUB en ligne ?

Oui, vous pouvez accéder à Stainless Steel 2000 par Tom Bell, Katsuya Akamatsu, Tom Bell, Katsuya Akamatsu en format PDF et/ou ePUB ainsi qu’à d’autres livres populaires dans Technology & Engineering et Materials Science. Nous disposons de plus d’un million d’ouvrages à découvrir dans notre catalogue.

Informations

Towards Quantifying the Composition of Expanded Austenite

M.P. FEWELLa*, P. GARLICKb, J.M. PRIESTa†, P.T. BURKEc, N. DYTLEWSKIc, K.E. PRINCEc, K.T. SHORTc, R.G. ELLIMANd, H. TIMMERSd,e, T.D.M. Weijersd,e and B. GONGf

aPhysics and Electronics, University of New England, Armidale NSW 2351, Australia

bElectron Microscope Unit, University of New England, Armidale, NSW 2351, Australia

cAustralian Nuclear Science and Technology Organisation, Menai, NSW2234, Australia

dDepartment of Electronic Materials Engineering, Australian National University, Canberra, ACT 0200, Australia

eDepartment of Nuclear Physics, Australian National University, Canberra, ACT 0200, Australia

fSurface Science and Technology, School of Chemistry, University of New South Wales, Sydney, NSW 2052, Australia

This paper is dedicated to the memory of Trevor Richard Ophel, Professor of Nuclear Physics in the Australian National University, who died suddenly on 17th June 2000.

ABSTRACT

Secondary-ion mass spectrometry (SIMS) is an attractive method for elemental depth profiling for nitrided stainless steel. However, if taken at face value, the results suggest migration of Mo and Cr from the nitrogen-rich layer. More plausibly, the results indicate the presence of significant matrix effects, and this conclusion casts doubt on the interpretation of all the SIMS depth profiles, including that of nitrogen. We explored this question by examining standard samples prepared by nitrogen-ion implantation and comparing assays and depth profiles from SIMS, energy-dispersed X-ray microanalysis (EDX), heavy-ion elastic-recoil detection analysis (HI-ERDA) and X-ray photoelectron spectroscopy (XPS). We conclude that there are negligible matrix effects in the SIMS sputter yields of nitrogen and carbon, but that the yields of MoCs+ and CrCs+ ions are significantly affected by the concentration of nitrogen. Thus, the shape of the nitrogen and carbon depth profiles from SIMS can be taken at face value. HI-ERDA gives depth profiles of the same quality as SIMS, but is limited to a relatively thin nitrogen-containing layer. Results from EDX, HI-ERDA and XPS show that the relative concentrations averaged over the treated layer of the main metals in the alloy are the same as in the bulk material. Detailed examination of the peak positions and widths in XPS shows a clear chemical association between the nitrogen in the treated layer and Cr and Mo, and probably also an N–Fe association, but none between nitrogen and Ni. These results support a model of the kinetics of nitriding in austenitic stainless steel.

1. INTRODUCTION

Stainless steel hardened by nitriding is potentially such a useful material, and plasma nitriding gives such promise of a commercially practicable method of producing it, that much effort world wide is now being devoted to realising this potential.1, 2, 3, 4, 5 As in many other fields, a significant issue for this research is the characterisation of treated samples, for the purpose of comparing the efficacy of different treatment processes. Many diagnostic methods are used; among them are techniques for determining the composition of the treated layer. These range from methods familiar in metallurgy, such as glow-discharge optical spectroscopy, to the most sophisticated techniques developed in modern surface science. A feature of all methods is the need for calibration: whether one is measuring the yield of photons, electrons or ions, there is always the question of relating the observed yield to the concentration of the various species in the material under study. The work reported in this paper was prompted by just such a question of calibration, in this case in the results of secondary-ion mass spectrometry (SIMS) on samples of nitrided AISI 316 stainless steel.

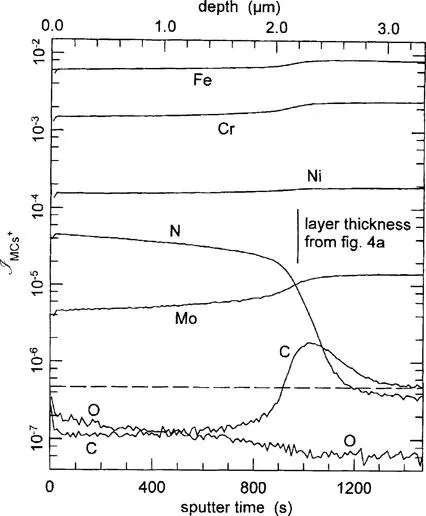

Figure 1 shows a typical SIMS elemental depth profile from a nitrided sample. (Experimental details are given in §§ 2.1 and 2.2.) There are many interesting features in these data, not least the shape of the profiles for carbon and nitrogen. However, the profiles for the four main alloy elements indicate that the interpretation may not be straightforward. All four metals show a lower ion-current ratio ℐMCs+ in the nitrogen-containing layer compared with the bulk. This is to be expected from sputtering theory, which indicates that the ion-current ratio of a species M should be proportional to its atomic concentration cM (atom %), and cM values for the metal elements are reduced by the presence of the nitrogen. But closer inspection shows that the details do not match this explanation. Table 1 gives the ratio of ion-current ratios in the treated layer to the bulk for the four main alloy elements. A straightforward interpretation would explain the value for iron as reflecting a ~25 at. % concentration of nitrogen in the treated layer. However, one would then expect the values to be the same for all the metals, and clearly they are not. Either there has been migration of Cr and Mo from the treated layer, or the ion-current ratios of these elements are influenced by the presence of nitrogen differently from those of Fe and Ni. Given that Fe is the main constituent of the alloy (~65 at. %), there may even be evidence that ℐNiCs+ is behaving in an opposite manner from ℐCrCs+ and ℐMoCs+.

Influences of this sort are referred to as ‘matrix effects’; their presence clearly complicates the interpretation of depth profiles. One can no longer assume that, for example, a halving of ℐMCs+ implies a halving of cM; rather there may be a change in the calibration factor relating these two. Of the elements profiled in Fig. 1, most interest perhaps lies in nitrogen and carbon, but there is no reason why the profiles of these should be less affected by matrix effects than the profiles of the meta...