eBook - ePub

Ultra-Clean Technology Handbook

Volume 1: Ultra-Pure Water

Tadahiro Ohmi

This is a test

Partager le livre

- 944 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

eBook - ePub

Ultra-Clean Technology Handbook

Volume 1: Ultra-Pure Water

Tadahiro Ohmi

Détails du livre

Aperçu du livre

Table des matières

Citations

À propos de ce livre

Evaluating the effectiveness of conventional wet processes for cleaning silicon wafers in semiconductor production, this reference reveals concrete measures to improve ultrapure water quality reviewing the structure and physical characteristics of ultrapure water molecules.

Foire aux questions

Comment puis-je résilier mon abonnement ?

Il vous suffit de vous rendre dans la section compte dans paramètres et de cliquer sur « Résilier l’abonnement ». C’est aussi simple que cela ! Une fois que vous aurez résilié votre abonnement, il restera actif pour le reste de la période pour laquelle vous avez payé. Découvrez-en plus ici.

Puis-je / comment puis-je télécharger des livres ?

Pour le moment, tous nos livres en format ePub adaptés aux mobiles peuvent être téléchargés via l’application. La plupart de nos PDF sont également disponibles en téléchargement et les autres seront téléchargeables très prochainement. Découvrez-en plus ici.

Quelle est la différence entre les formules tarifaires ?

Les deux abonnements vous donnent un accès complet à la bibliothèque et à toutes les fonctionnalités de Perlego. Les seules différences sont les tarifs ainsi que la période d’abonnement : avec l’abonnement annuel, vous économiserez environ 30 % par rapport à 12 mois d’abonnement mensuel.

Qu’est-ce que Perlego ?

Nous sommes un service d’abonnement à des ouvrages universitaires en ligne, où vous pouvez accéder à toute une bibliothèque pour un prix inférieur à celui d’un seul livre par mois. Avec plus d’un million de livres sur plus de 1 000 sujets, nous avons ce qu’il vous faut ! Découvrez-en plus ici.

Prenez-vous en charge la synthèse vocale ?

Recherchez le symbole Écouter sur votre prochain livre pour voir si vous pouvez l’écouter. L’outil Écouter lit le texte à haute voix pour vous, en surlignant le passage qui est en cours de lecture. Vous pouvez le mettre sur pause, l’accélérer ou le ralentir. Découvrez-en plus ici.

Est-ce que Ultra-Clean Technology Handbook est un PDF/ePUB en ligne ?

Oui, vous pouvez accéder à Ultra-Clean Technology Handbook par Tadahiro Ohmi en format PDF et/ou ePUB ainsi qu’à d’autres livres populaires dans Sciences physiques et Chimie industrielle et technique. Nous disposons de plus d’un million d’ouvrages à découvrir dans notre catalogue.

Informations

II

Ultrapure Production Systems

1

Introduction

Kurita Water Industries, Ltd., Tokyo, Japan

Natural water to be processed to ultrapure water contains various impurities that cannot be completely removed by any single method. To remove these impurities completely, various processing technologies are combined to build an ultrapure water production system. This system is composed of a pretreatment system, a primary treatment system, an ultrapure water system, a piping system, and a wastewater reclamation system.

The design of an ultrapure water production system requires a full understanding of the characteristics and behavior of natural water, as well as the characteristics and limitations of each technology applied to each component system. At the initial stage, existing technologies for the water supply to a boiler were merely adapted. Since it was revealed that these existing technologies were incapable of dealing with the high purity level demanded for ultrapure water, however, great efforts have been made to develop new technologies as well as to improve existing technologies. The present technologies of ultrapure water production in the semiconductor field are advanced enough to cope with the higher purity level and larger quantity required.

The primary pure water system is mainly composed of a reverse osmosis unit, a deaerator, and an ion-exchange unit. The functions of the reverse osmosis membrane are critical, and improvements in the reverse osmosis membrane have contributed markedly to progress in the ultrapure water production system. The ion-exchange unit is also vital to remove inorganic ions economically.

The ultrapure water system is mainly composed of an ultraviolet (UV) sterilization unit, an oxidation unit, an ion-exchange unit, and an ultrafiltration unit. The ultrafiltration unit plays an important role as the final filter for removing trace particles and bacteria. Ultrafiltration technology, the technology peculiar to ultrapure water, has been developed and upgraded.

A piping system is required to distribute ultrapure water with high purity to use points without degrading its quality. Specific technologies have been developed for piping materials, the design of piping networks, installation, cleaning, and sterilization.

The wastewater recycling system is composed of a reverse osmosis unit, an active carbon adsorption unit, an ion-exchange unit, and a UV oxidation unit. In Japan, the wastewater reclamation system is relatively prevalent as one countermeasure to deal with restrictions on industrial water consumption and cost increases. Based on 10 years of experience, the basic technology for wastewater reclamation has been established.

2

Pretreatment System

Shinko Pantec Co., Ltd., Kobe, Japan

I. PURPOSE OF PRETREATMENT

Ultrapure water is produced by treating various kinds of source water in various processes. An effective ultrapure water production system must be designed for the stable production of ultrapure water of the required quantity and quality at a low cost. An ultrapure water production system is usually composed of a pretreatment system, a primary treatment system, a secondary treatment system, and a distribution piping system.

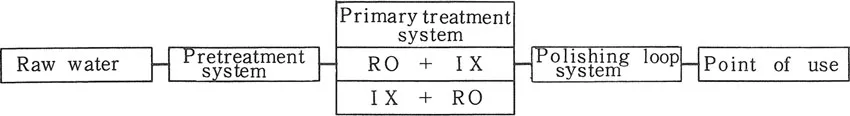

Several treatment methods can be applied in the primary treatment system, depending on the quality of the raw water and the process characteristics. As shown in Fig. 1, these methods can be divided into two major types; the RO + IX type where a reverse osmosis unit (RO) is placed upstream of an ion-exchange unit (IX); and the IX + RO type where the RO unit is placed downstream of the IX unit.

Figure 1 Process flow of ultrapure water treatment system.

The primary treatment system, followed by the polishing system (the secondary treatment system), is an important system that removes 99–99.99% of the impurities contained in raw water. The pretreatment system must therefore be designed and installed to secure its safe and perfect performance.

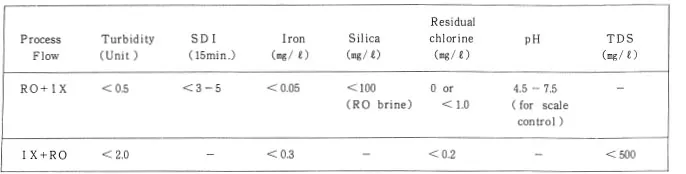

The pretreatment process depends on the type of primary treatment system that follows it. Table 1 compares the difference of the inlet water quantity required by RO + IX and IX + RO. The inlet water quality in IX + RO is not as crucial as that in RO + IX. City water in Japan well satisfies the requirements of the IX + RO. On the other hand, in the RO + IX, in which pretreated water is directly fed to the reverse osmosis unit, much attention should be paid to pretreatment to avoid fouling the reverse osmosis unit.

Table 1 Inlet Water Quality for RO + IX Versus IX + RO Systems

In current ultrapure water production systems, membrane filtration by reverse osmosis and ultrafiltration, for example, is employed at some point in the process. Therefore, one of the important challenges to successfully operate an ultrapure water production system is to secure the stable performance of the membrane filtration unit. In the IX + RO type, effective and stable reverse osmosis operation can be expected because the ionexchange unit removes suspended matter and the dissolved salts that cause scaling, which leads to fouling of the subsequent reverse osmosis unit. The IX unit also reduces coagulation and adhesion in the membrane module by lowering the interface potential. On the other hand, the RO + IX type is widely employed because it can save cost, space, and energy as well as reduce wastewater by making the best use of the demineralization function that is a feature of reverse osmosis.

Table 2 lists typical types of fouling of the reverse osmosis system and countermeasures to prevent them. This ch...