eBook - ePub

Bearing Capacity Of Roads

A. Gomes Correia

This is a test

Partager le livre

- 800 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

eBook - ePub

Bearing Capacity Of Roads

A. Gomes Correia

Détails du livre

Aperçu du livre

Table des matières

Citations

À propos de ce livre

This book is an outcome of the sixth conference on bearing capacity of roads and airfield held in Lisbon, Portugal. It focuses on railway tracks and covers following topics: bearing capacity policies, concepts, costs and condition surveys; analysis and modelling; design and environmental effects.

Foire aux questions

Comment puis-je résilier mon abonnement ?

Il vous suffit de vous rendre dans la section compte dans paramètres et de cliquer sur « Résilier l’abonnement ». C’est aussi simple que cela ! Une fois que vous aurez résilié votre abonnement, il restera actif pour le reste de la période pour laquelle vous avez payé. Découvrez-en plus ici.

Puis-je / comment puis-je télécharger des livres ?

Pour le moment, tous nos livres en format ePub adaptés aux mobiles peuvent être téléchargés via l’application. La plupart de nos PDF sont également disponibles en téléchargement et les autres seront téléchargeables très prochainement. Découvrez-en plus ici.

Quelle est la différence entre les formules tarifaires ?

Les deux abonnements vous donnent un accès complet à la bibliothèque et à toutes les fonctionnalités de Perlego. Les seules différences sont les tarifs ainsi que la période d’abonnement : avec l’abonnement annuel, vous économiserez environ 30 % par rapport à 12 mois d’abonnement mensuel.

Qu’est-ce que Perlego ?

Nous sommes un service d’abonnement à des ouvrages universitaires en ligne, où vous pouvez accéder à toute une bibliothèque pour un prix inférieur à celui d’un seul livre par mois. Avec plus d’un million de livres sur plus de 1 000 sujets, nous avons ce qu’il vous faut ! Découvrez-en plus ici.

Prenez-vous en charge la synthèse vocale ?

Recherchez le symbole Écouter sur votre prochain livre pour voir si vous pouvez l’écouter. L’outil Écouter lit le texte à haute voix pour vous, en surlignant le passage qui est en cours de lecture. Vous pouvez le mettre sur pause, l’accélérer ou le ralentir. Découvrez-en plus ici.

Est-ce que Bearing Capacity Of Roads est un PDF/ePUB en ligne ?

Oui, vous pouvez accéder à Bearing Capacity Of Roads par A. Gomes Correia en format PDF et/ou ePUB ainsi qu’à d’autres livres populaires dans Technology & Engineering et Civil Engineering. Nous disposons de plus d’un million d’ouvrages à découvrir dans notre catalogue.

Informations

Analysis and modeling

A Simple Damage Approach to Modelling Fatigue in Bituminous Materials

DOI:10.1201/9781003078814-11

ABSTRACT: Results from laboratory fatigue testing indicate that the effective stiffness modulus of asphaltic material can be reduced significantly under repeated loading without the presence of visible cracking. This indicates that damage is accumulating in the asphaltic material thus reducing the effective volume able to carry the applied load (and hence reducing the effective stiffness modulus). Damage mechanics characterises the state of a material under mechanical loading by a dimensionless scalar variable (known as damage). This paper describes the application of continuum damage mechanics in a simple way to model fatigue of asphalt mixtures. A specimen for uniaxial testing has been developed and a set of stress controlled fatigue tests have been performed over a range of temperatures and stress levels. The results have been used to determine a simple evolution law for the rate of damage accumulation. Trapezoidal cantilever (2-point bend) tests have also been performed and the results have been compared to results from the uniaxial test.

KEYWORDS: Damage mechanics, fatigue cracking, stiffness reduction, uniaxial test

1 INTRODUCTION

There are many different approaches to modelling fatigue and fracture in bituminous materials, ranging from simple models (e.g. tensile strain) to more complicated approaches using fracture mechanics and damage mechanics. Traditionally, fatigue is divided into two stages; crack initiation and crack propagation. Crack initiation has been defined as the growth and coalescence of microcracks and crack propagation has been defined as the growth of macro-cracks (Suresh, 1991). Results from laboratory fatigue testing and full-scale accelerated trials indicate that the effective stiffness modulus of an asphaltic material can be reduced significantly under repeated loading without the presence of visible cracking. This indicates that damage is accumulating in the material thus reducing the effective volume able to carry the applied load (and hence reducing the effective stiffness modulus).

Continuum damage mechanics evolved in the 1960s as a way of representing the collective effect of crack-like defects on deterioration under mechanical loading (Lemaitre, 1996). Typically, the state of a material is characterised by a dimensionless scalar variable (known as damage) which ranges from 0 (undamaged) to 1 (fully damaged). This paper describes the application of continuum damage mechanics in a simple way to model fatigue of asphalt mixtures.

2 DAMAGE MECHANICS

From damage mechanics concepts, the internal damage to a body can be expressed in terms of a reduction in the effective area under uniaxial conditions (Kachanov, 1986), as follows:

(1)

where AD = area of flaws and A = area of the whole plane. It is clear that D is bounded by 0 (undamaged) and 1 (fully broken in two parts).

It was suggested by Lemaitre (1996) that the above equation should be re-expressed in terms of elastic (Young’s) modulus. For pavement engineering applications, the stiffness modulus can be used as follows:

(2)

where Se is effective stiffness modulus; and S is modulus of the intact material.

Assuming the internal damage gradually evolves as the number of loading cycles increases, the rate of damage growth per cycle could be expressed as a function of some critical parameters which represent the material characteristics and testing conditions, as follows:

(3)

where a is stress, ɛ is strain and T temperature.

3 UNIAXIAL FATIGUE TESTS

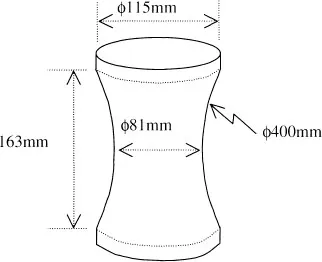

Data from uniaxial fatigue tests can be used to develop the function f in Equation 3 for one dimensional stress conditions. However, one of the most difficult aspects of the uniaxial fatigue test is the uncertainty of the failure position. A predictable failure position is necessary to measure accurate physical properties and to obtain reliable and stable test results. Therefore, a specimen with a necked central section has been developed. Figure 1 shows the details of the specimen geometry.

A mixture based on the specification for a 14 mm close graded wearing course Dense Bitumen Macadam (DBM) was selected for the test programme (BS 4987, 1988). Limestone aggregates and a 50 pen grade of bitumen were used in the mixture. The specimens were manufactured using a specially designed mould. A combination of static and vibratory compaction was used to achieve the required specimen density (air void content). After compaction the specimens were placed in the uniaxial testing machine (see Fig. 2) where they were subjected to sinusoidal loading (load control) at a frequency of 10 Hz.

Two Linear Variable Differential Transformers (LVDTs) were attached to the specimens (at diametrically opposite locations) to measure displacements over the central 60 mm of the necked section. The two LVDT readings were averaged and divided by the gauge length (60 mm) to provide a local strain measurement. A load cell was used to measure the applied force. The stress acting on the central section of the specimen was calculated and divided by the local strain to determine the stiffness modulus of the material. The test was continued until the specimen failed.

3.1 Investigation of Fatigue Behaviour

Figure 3 shows a typical set of stiffness modulus results plotted as a function of number of load a...