eBook - ePub

Latex Dipping

Science and Technology

David M. Hill

This is a test

Partager le livre

- 259 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

eBook - ePub

Latex Dipping

Science and Technology

David M. Hill

Détails du livre

Aperçu du livre

Table des matières

Citations

À propos de ce livre

Latex products that we use in everyday life have a great impact on health and lifestyle. This book gives a comprehensive overview of how raw materials are prepared for latex manufacture and how they are converted to products by modern latex dipping methods. Tools for how to solve production problems encountered, quality control and how to validate the processes used in the latex industry are thoroughly discussed and described.

Foire aux questions

Comment puis-je résilier mon abonnement ?

Il vous suffit de vous rendre dans la section compte dans paramètres et de cliquer sur « Résilier l’abonnement ». C’est aussi simple que cela ! Une fois que vous aurez résilié votre abonnement, il restera actif pour le reste de la période pour laquelle vous avez payé. Découvrez-en plus ici.

Puis-je / comment puis-je télécharger des livres ?

Pour le moment, tous nos livres en format ePub adaptés aux mobiles peuvent être téléchargés via l’application. La plupart de nos PDF sont également disponibles en téléchargement et les autres seront téléchargeables très prochainement. Découvrez-en plus ici.

Quelle est la différence entre les formules tarifaires ?

Les deux abonnements vous donnent un accès complet à la bibliothèque et à toutes les fonctionnalités de Perlego. Les seules différences sont les tarifs ainsi que la période d’abonnement : avec l’abonnement annuel, vous économiserez environ 30 % par rapport à 12 mois d’abonnement mensuel.

Qu’est-ce que Perlego ?

Nous sommes un service d’abonnement à des ouvrages universitaires en ligne, où vous pouvez accéder à toute une bibliothèque pour un prix inférieur à celui d’un seul livre par mois. Avec plus d’un million de livres sur plus de 1 000 sujets, nous avons ce qu’il vous faut ! Découvrez-en plus ici.

Prenez-vous en charge la synthèse vocale ?

Recherchez le symbole Écouter sur votre prochain livre pour voir si vous pouvez l’écouter. L’outil Écouter lit le texte à haute voix pour vous, en surlignant le passage qui est en cours de lecture. Vous pouvez le mettre sur pause, l’accélérer ou le ralentir. Découvrez-en plus ici.

Est-ce que Latex Dipping est un PDF/ePUB en ligne ?

Oui, vous pouvez accéder à Latex Dipping par David M. Hill en format PDF et/ou ePUB ainsi qu’à d’autres livres populaires dans Ciencias físicas et Química industrial y técnica. Nous disposons de plus d’un million d’ouvrages à découvrir dans notre catalogue.

Informations

1 Raw materials

1.1 Polymer latex or polymer solution?

In general, polymer latices are the material of choice for dipping, rather than solutions, for the following reasons. Unless the polymer is of a low molecular weight (MW) or at a low concentration, polymer solutions are viscous, which will result in problems with flow and controlling pick-up, and are prone to air being entrained giving rise to bubbles and possibly holes in the finished product. If the solution is diluted to a lower viscosity, the finished rubber film will be thin and several dips will be required to give a useable product. Latices, on the other hand, can be of a high solids content – typically 45 to 60% – coupled with a much lower viscosity. Polymer solutions are usually based on an organic solvent, which can be flammable, toxic or both, whereas latices are water based. It is possible to obtain aqueous solutions of some polymers, but the constraints of solids content and viscosity still apply. Some products are dipped from polymer solutions – for example, polyurethane (PU) condoms and some electricians’ gloves – but for the reasons outlined above, the overwhelming majority of dipped elastomeric products are formed by dipping latex. The nomenclature used here follows that described by Blackley [1]. Natural latices are produced via metabolic processes in trees and other plants, synthetic latices are produced by emulsion polymerisation of the relevant monomers and artificial latices are produced by dispersing the polymer (however, it may have been produced) in water.

Not all latices, however, are suitable for dipping. The polymer has to be film-forming at the temperatures used in the process – that is, the individual polymer particles which comprise the latex must be able to lose their individual identity and fuse together into a coherent film. The subject of film-forming will be dealt with in more detail in a later chapter, but these requirements mean that there are relatively few latices that are used commercially in dipping. Those in significant use are:

- – Natural rubber (NR).

- – Acrylonitrile-butadiene rubber [‘nitrile’ rubber (NBR)] and carboxylated nitrile rubber (XNBR).

- – Polychloroprene (CR) or chloroprene rubber. ‘Neoprene’, the trade name of DuPont’s CR, is in general use for this material.

- – Styrene-butadiene rubber (SBR) latex, although widely used in applications such as carpet backing and foam rubber, it is rarely used in dipping applications, although it can be incorporated into other latex formulations as a reinforcing filler.

There are also some artificial latices which are suitable for dipping and include:

- – Synthetic cis-1,4-polyisoprene rubber (IR) – the synthetic version of NR latex.

- – PU rubber.

- – Isoprene-isobutylene rubber (IIR) (‘butyl’rubber).

- – Ethylene-propylene diene monomer rubber (EPDM).

- – Chlorosulfonated polyethylene rubber (CSR).

Of these artificial latices, only the IR latex is currently being used to a significant extent in the dipping industry.

There are many other types of latices but none is used commercially to produce dipped rubber articles, although as mentioned above, SBR latex can be used as a reinforcing filler, as can polymethyl methacrylate (PMMA) latex.

1.1.1 Natural rubber latex

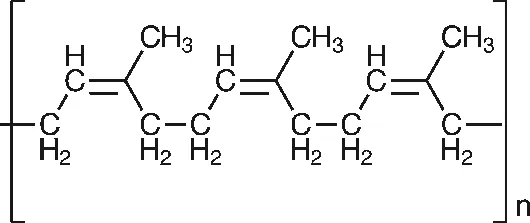

NR latex is a high molecular weight (up to 106 daltons) polymer of cis-1,4-polyisoprene, produced by the rubber tree Hevea Brasiliensis, which as the name implies, is a native of South America. to Kew Gardens in London towards the end of the 19th century. Seeds of the rubber tree were taken by the British explorer Sir Henry Wickham from Brazil Some of the seeds germinated, and seedlings were then transferred to Sri Lanka and Singapore, starting the cultivation of rubber in South- East Asia. Successful cultivation of the tree requires a tropical environment, with high temperatures and high annual rainfall. It is usually grown at lower levels and is rarely seen above 400 m. Intensive study over the years has resulted in the development of many different clones of the original strain, selected for high yield, rapid growth and resistance to disease. The structure of the NR molecule is shown in Figure 1.1.

Although NR is grown in many countries nowadays, at the time of writing the main production areas are in South East Asia, principally Thailand, Indonesia and Malaysia, Vietnam and India. There is also significant production in China, Sri Lanka, the Philippines and Cambodia, with smaller amounts in Africa (principally Liberia) and Central America. The production of NR latex in its original home in the Brazilian rainforests is still low, in part because of a fungal infection, South American leaf blight, to which the rubber tree is prone.

NR latex is present in the tree in specialised cells known as latex vessels, located just behind the outer bark of the tree. Synthesis of the polymer by the tree follows a complicated biological pathway and is not the result of isoprene monomer polymerisation. Instead, naturally occurring carbohydrates are converted via a complicated biological process into isopentenyl pyrophosphate, an important intermediary in many biosynthetic pathways. Isopentenyl pyrophosphate can, under certain conditions, form polyisoprenes via a condensation polymerisation. Detailed descriptions of the biosynthesis of NR in the rubber tree can be found in Natural Rubber Science and Technology by Roberts [2] and Polymer Latices Science and Technology by Blackley [3].

Latex is collected from the tree by the tapping process. A cut is made through the bark into the latex vessels, causing the latex to bleed out into a cup (Figure 1.2). It is important that the cut is not made too deep into the tree, as this would damage the tree and cause the bark to regrow irregularly, making subsequent tapping more difficult. Specialised knives are used to make the cut, and the operation requires a certain amount of skill to carry it out correctly.

As the latex vessels spiral clockwise up the tree, the cut will generally be made diagonally downwards, from high on the left-hand side to low on the right-hand side. This way, the maximum number of latex vessels are opened up. The latex flows out readily at first, then slows down and eventually dries up. Tapping is normally carried out early in the morning when the flow of latex is highest and temperatures (and hence the rate of drying) are lower. The yield from each tree depends on many factors, including the particular clone, the size of the tree and the age at which it was first tapped, amongst others. The trees will be tapped again, reopening the cut by shaving off as little of the bark as possible. Although some clones can be retapped daily, retapping generally takes place on alternate days, as the quality of the latex can be reduced by more frequent tapping. The latex will coagulate and dry if left, and is also prone to microbiological spoilage. For this reason, it is usual to put some ammonia into the collecting cup which prevents putrefaction and helps keep the latex liquid. The tapper will return to collect the latex from the collecting cup a few hours later and add it to the latex collected from the other trees. The bulked latex is transferred to the collecting station and from there onto the concentration factory. On arrival at the factory, the latex will be analysed to establish its quality, which will determine whether it is used to produce latex concentrate or dry rubber. Typically, this field latex will have a rubber content of around 30 to 35%. For subsequent use, the latex is concentrated to give a dry rubber content of about 60 to 65% – above this the viscosity rises rapidly and the latex becomes increasingly difficult to handle and process. The rubber particles have a density of around 0.92 kg/m3 and so are lighter than the aqueous phase in which they are dispersed. This density difference allows the latex to be concentrated by centrifuging. Latex can also be concentrated by creaming or evaporation, although most latex used for dipping is centrifuged. C...