![]()

Chapter 1

The food industry

This chapter looks at the food manufacturing industry and begins by looking at some of the reasons behind Lean Manufacturing.

Pressures in the food manufacturing industry

As you begin to read this book, it is important that you spend a few minutes putting your work into the bigger picture, so that you can appreciate the reasons behind some of the issues you have now or could have in the future. This will also help you come up with better solutions that will sustain you for longer.

Reasons why the food manufacturing industry is unique

Political food

The food industry is very important to a lot of people in this country. The supply of safe, affordable and plentiful food is essential to the well-being of the nation, as well as to the political success of the people running the country.

There is hardly a week goes by without a food story hitting the headlines. This could be a food safety scare, an increase in prices, food retailers making massive profits or even a secret camera being taken inside a food factory. Add to that the public’s concerns over packaging and waste, food miles and obesity, and you can see just how big a part of people’s everyday life is impacted by the food industry.

Governments know that people are interested in the safety and price of the food they eat. Everyone also appears to be increasingly interested in where their food comes from, how it is reared or grown and if it has the required nutritional content. Because of this need to deliver food safety and value, the food industry is heavily regulated to ensure that nothing goes wrong.

The food business

The food industry is a massive business. In order to keep the nation fed, a huge quantity of food has to be shipped each day from the farms to factories and then to the retailers and ultimately the consumers. The need for reliability in this supply chain is paramount for the consumer to be satisfied at a price they are willing to pay. Food retailers know that their shoppers are very sensitive to issues in the supply chain. If a food product is unavailable in a store, the consumer may well look elsewhere and the store will have lost business, not only for that product but for the rest of the shopping basket as well. Availability of products in store is therefore a very important factor in food factories; ensuring that deliveries are made “on time” and “in full” is a major task.

The food retailers also compete in terms of the prices of the products on sale in their stores. This pressure on prices is passed back to the food factories in the form of small profit margins. Low margins and high delivery performance will place stress and strain on food businesses and the people that work in them. In order to perform well in the food business, costs have to be controlled and minimised, and performance has to be at a high level and consistent. A food factory that under-performs in any of the areas of its activity will soon run into difficulties with its customers, as in any other businesses. The difficulty in the food manufacturing industry is that the level of high performance has to be maintained day in, day out, with low profit margins meaning that slacking and duplication in the systems cannot be afforded. A food factory cannot afford to have a spare production line, “just in case of a breakdown”. It cannot afford to have spare raw material stocks, “just in case we have a process fault and have to reject some products”. It cannot usually afford to have spare anything! The work of a food factory has to be right first time, every time (see Figure 1.1).

Food fashion

Consumers of food – that is everyone, are constantly being tempted to buy new and exciting foods. There are launches of new food products on an almost daily basis, from companies trying to persuade consumers to buy their products. A large number of food products do not survive for long in the marketplace, as they are constantly replaced by a “new improved” version, or the sales decline because the consumers have moved on to a new product. For the food factories, this constant stream of new products has its own set of demands and pressures that need to be controlled. The food retailers are constantly trying to excite their customers with new products and an every increasing range of foods. The massive variety of foods available in retail outlets has a big impact on the work of food manufacturers. The number of different raw materials and processes that are needed to manufacture the products means that food factories are becoming increasingly complex places to work. The warehouses for raw materials and packaging need to be well managed, to maintain control of the quantity and location of the stock. There is nothing more frustrating in a food factory than the words “I know we have got some … now where did I see it?”

The complexity of the factory will also have an impact on the methods of production. The rapidly changing fashions in food mean that no one in the food supply chains want to get caught with excess stock. There is nothing worse than having a large stock of a specialist raw material when the fashion changes, except perhaps having a large stock of packaging material! As a result, manufacturing operations have to be set up to be very flexible to meet demand. The way that food manufacturers have responded to the food fashion aspect of the business is to make little and often. This has always been a feature in short shelf-life foods, such as chilled products, bread and fresh produce, but is increasingly used in factories that manufacture long-life products, such as frozen and canned foods, biscuits and preserves.

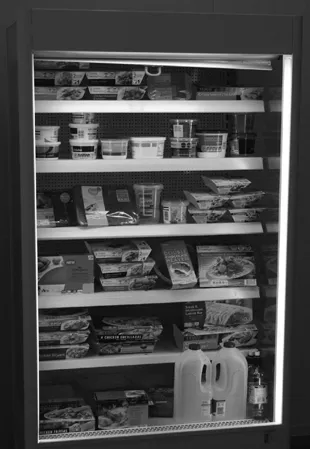

Food fashion has taken food manufacturers into the area of low stocks and flexible manufacturing. This appears on the shop-floor as short production runs, multiple line changeovers, complex material controls and a need for precise, right-first-time production (see Figure 1.2).

Why do we bother?

“Why don’t we make something else for a living?”

The food industry has great rewards, if you get it right. The food industry is a massive business and if a factory performs well it will grow. The food industry is seen as “recession proof”; people have got to eat! Indeed, during periods of economic downturn, the food that people eat has been know to increase in value, as they look for comfort and shelter from the economic storm.

Questions

Have a think about your factory – answer the following questions:

- How many new products have you launched in the last year?

- When was the last time your factory failed to deliver what your customer wanted?

- When was the last time you saw a food story on the TV?

The major retailers can be very demanding of their suppliers in terms of technical standards, delivery performance and price, but they do give a manufacturer access to a massive customer base. The volume of product sold through the major retailers allows the manufacturer to run a large-scale operation and as a result they benefit from lower costs. The economies of scale in the food business mean that the more you manufacture, the cheaper each item becomes. The price, to the manufacturer, of raw materials and packaging materials will reduce as the volume increases. The costs of energy and distribution are also related to the quantity bought, therefore, the bigger the business, the lower the prices.

Well, at least that is the theory. The food business is very complex so sometimes the normal rules do not apply for short periods, but in the medium and long term the rules will have to be applied if businesses are to make a reasonable profit and thrive.

There follows some more reasons why the food industry is unique.

Food materials

The raw materials used in the manufacture of food are natural products that are either grown or reared on a farm. Occasionally, manufactured or artificial ingredients are used, but this is becoming increasingly rare as the industry caters for consumers that want their food made without these ingredients and so regulations control their use. If the material is meat for a sausage or flour for a loaf of bread, sugar for a biscuit or vegetable oil for pastry, the vast majority of raw materials originate on the farm. These natural materials are not often uniform, so variation will occur from crop to crop or animal to animal. The variation will also occur from season to season and year to year as the growing conditions change due to rainfall, temperatures or if the practices on the farm alter. The food industry tries to produce products to meet the specification, but variation in raw materials means that the processes used will rarely be static and often need to be altered to compensate for the raw material variation. That said, a focus on your raw material suppliers will allow you to minimise the variation that hits your process and at the very least, with careful management, predict the effect of that next batch of flour or consignment of strawberries.

What all this means to a food factory, and those trying to manage the process, is that even if your process today is identical to your process yesterday, it does not necessarily follow that the same quality, yield, efficiency and waste levels will be achieved. For this reason, one aspect of Lean Manufacturing focuses on monitoring and control of process performance, so that corrective actions can be taken before a raw material variation becomes a rejected product (see Figure 1.3).

For all the above reasons, the use of Lean Manufacturing techniques in a food factory is different to those same techniques used in a car plant or a factory making mobile phones!

24/7

Pressure on profit margins and the need to supply large quantities of food has lead to the growth of increasingly large food factories, which are often running for 24 hours a day, 7 days a week. This high intensity of manufacture often means that those managing the shop-floor are part of a shift system and that their performance is reliant on the performance of others who they rarely meet. The need for teamwork in the food industry is vital to its success and that teamwork has to extend to people who are in a different department, on a different shift or even on a different site. Add to this the demands posed by the need for high performance and it can be seen that managing a food production operation is a highly demanding role that needs to be done well if performance is to be maintained, and is even more demanding if performance is to be improved. Later in this book, costs of manufacture are discussed in more detail. It is very important that all members of a team in such a demanding industry have knowledge of the pressures on the business, their role in the team and that the overall aims and objectives are clear. In a factory that is implementing Lean Manufacturing techniques, everyone must be given the opportunity to contribute to the improvement of the business. This is particularly the case in the food manufacturing industry, where high performance and low cost is not just demanded by the retailers, but is the only way that a business will survive and grow in such a competitive market.

Alternative methods of lowering costs

First, you should spend some time looking at the way that a food manufacturing business works from a financial point of view. An understanding of the costs of the business, and how they are monitored and controlled, will help in the application and understanding of Lean Manufacturing techniques.

In a food business, costs are the one factor that needs to be considered alongside each and every decision. Food safety, quality and service level are also vital in the day-to-day running of the business, but unless the costs are under control the business will have a big problem.

Keeping costs at, or better than...