- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Here, in one volume, is all the architect needs to know to participate in the entire process of designing structures. Emphasizing bestselling author Edward Allen's graphical approach, the book enables you to quickly determine the desired form of a building or other structure and easily design it without the need for complex mathematics. This unique text teaches the whole process of structural design for architects, including selection of suitable materials, finding a suitable configuration, finding forces and size members, designing appropriate connections, and proposing a feasible method of erection. Chapters are centered on the design of a whole structure, from conception through construction planning.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Designing a Series of Suspension Footbridges

- Basic definitions of statics: loads, forces, tension, compression, stress

- Free-body diagrams; vectors and scalars; static equilibrium of concurrent forces

- The force polygon and funicular polygon for funicular structures; Bow's notation

- Detailing steel rod elements in tension, and anchoring to rock

- Lateral stability; stiffening a tensile structure

- Construction detailing and planning

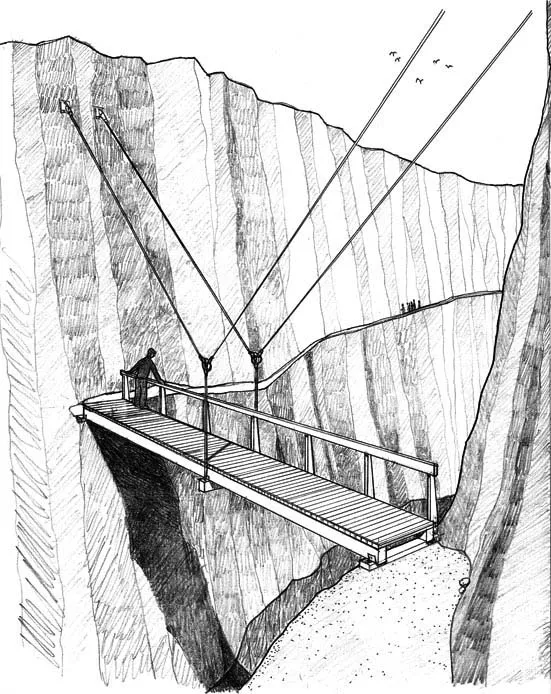

We have been commissioned to design a series of footbridges for a new scenic trail that will wind through a deep, narrow canyon in a national park in the southwestern United States. The walls of the canyon are often vertical and sometimes overhang, so that the trail must move from one side of the canyon to the other at a number of locations to follow a route that will avoid the steepest walls and minimize excavation of the rock. The lengths (spans) of the bridges will vary between 40 and 100 ft. The decks of all the bridges (the walking surfaces) will be 4 ft wide.

Design Concept

We have already developed, in cooperation with the Park Service, a basic design concept and a simple system of components for making these bridges (Figures 1.1, 1.2). Because of the remoteness of the bridge sites and the difficulty of working in the narrow canyon while standing on narrow rock ledges, as much of the work as possible will be done on components in a contractor's workshop. They will then be trucked to the site, where a construction crew will assemble them.

Figure 1.1 This suspension span of 40 ft is the first bridge we will consider in this chapter.

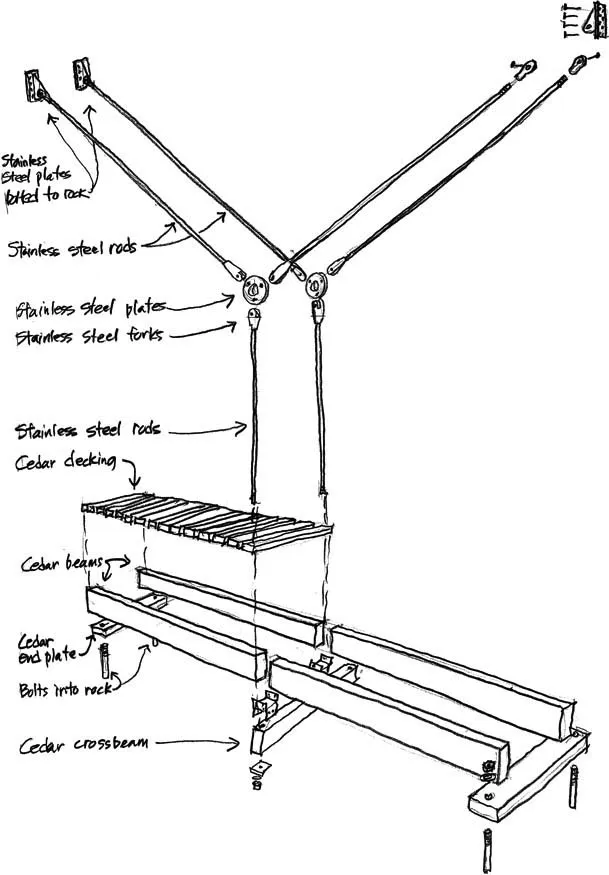

Figure 1.2 An exploded view of the construction system for the suspension bridges in this chapter reveals its component parts.

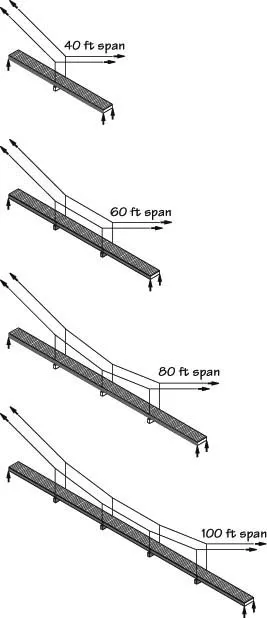

The beams of each bridge are made of wood and will be brought to the site in 20-ft lengths. Shorter lengths can be cut as needed to adjust bridge lengths to particular sites. We will support the ends of the beams that occur over the empty space of the canyon on short wood crossbeams that hang from steel rods. The rods will transmit their forces to steel plates anchored into the rock of the canyon walls. The beams, crossbeams, and rods will be used as a modular system to build suspension bridges of any necessary length for this trail (Figure 1.3). Suspension bridges tend to be lighter in weight than any other kind of bridge, which makes them particularly appropriate for the remote, difficult sites where they must be built in this park.

Figure 1.3 The construction system is modular, enabling it to be used for bridges of various spans.

We have selected rods rather than cables because these bridges are small and the loads to be supported are correspondingly low. Cables, if we were to use them, would be very small in diameter, which would make them vulnerable to vandalism. Because the steel from which the rods are made is not as strong as that used in cables, the rods that we will use will be somewhat larger in diameter than cables of the same capacity. Rods are also easier and less costly to connect than cables. We will learn about cables and their connections in Chapter 2, in the context of a structure with much longer spans, where cables are appropriate and economical.

The beams and deck boards for the bridges are sawn from red cedar logs. We will use them in their rough, unplaned state, in keeping with the rustic nature of the canyon. Furthermore, rough beams are enough larger in dimension than planed ones that they have substantially larger structural capacities. Red cedar contains natural substances that are toxic to decay fungi, making the wood resistant to rot. However, cedar is a very soft, low-density wood that erodes gradually when exposed to severe winter weather, losing a few hundredths of an inch from each surface every year. We have specified larger beams than are structurally necessary in order to provide for a few decades of erosion before they will have to be replaced.

With stainless steel rods and fittings, which do not rust, and cedar beams, which do not decay, the bridges will need no paint or chemical preservatives and should last for decades with little maintenance.

The Challenge

Our challenge is to design the bridges for this trail individually, taking into account for each of them the length of its span and the places above it where the rock is sufficiently solid to support the steel anchor plates. All the bridge sites have been surveyed to provide us with this information. As part of our design work, we need to determine the shapes that the rods will take in each situation, and the forces that they must transmit. This will enable us to specify the required lengths and diameters of the rods.

Construction Details

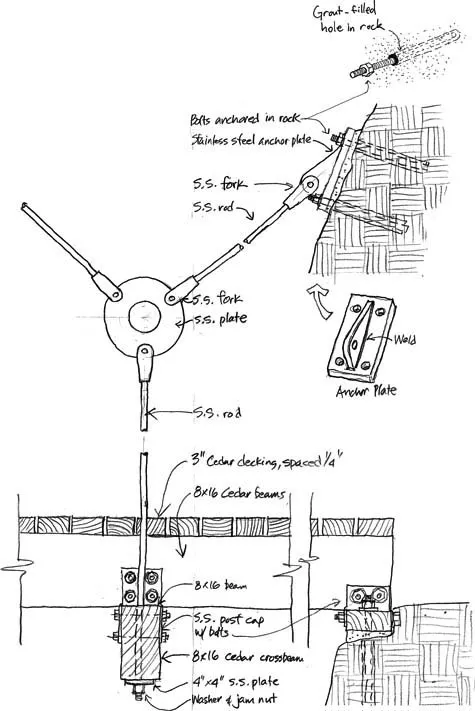

We have given considerable thought to how the bridges will be put together. Figure 1.4 shows details of the major features. The rods are connected to the rock walls of the canyon with stainless steel anchor plates. Each anchor plate is secured with stainless steel bolts that are inserted into holes drilled in the rock and embedded there with grout, a fine-grained, high-strength mixture of sand, portland cement, and chemical admixtures that increase its strength and limit its shrinkage. The grout is poured into the holes in the form of a paste that hardens to unite the bolts securely with the rock. The rods, anchor plate assemblies, and other metallic components are all custom-fabricated for each bridge. We will determine the diameters of the rods in accordance with the amount of force each must carry when the bridge is fully loaded.

Figure 1.4 Typical details of the suspension bridge construction system.

The fabricator of the steel rods will prepare them to the exact lengths needed for each bridge. A jaw fitting (also called a fork or clevis) will be used wherever a rod joins a plate. Where a rod supports a wood beam, it will pass vertically through a hole drilled in the beam and a matching hole in a stainless steel plate 3/8 in. thick on the bottom of the beam (Figure 1.4). A circular washer and stainless steel jam nut transmit the force in the rod securely to the plate. The plate spreads this force over a large enough area of wood that the wood is not crushed. The jam nut is designed to develop a high degree of friction against the threaded rod so that it will not unscrew accidentally. The screw threads and nuts allow for easy assembly and fine-scale adjustment of the vertical positions of the beams, as well as easy disassembly when needed.

Where a vertical rod from a beam meets the sloping rods from the rock anchors, we will attach the rods with forks to a circular steel plate connector, as shown in Figure 1.4. A jaw fitting at the bottom of the plate will transfer force from the vertical rod to the plate, and the plate will pass this same force to the sloping rods and thence to the anc...

Table of contents

- Cover

- Title Page

- Copyright

- Project Team and Contributors

- Acknowledgments

- Introduction

- Chapter 1: Designing a Series of Suspension Footbridges

- Chapter 2: Designing a Suspended Roof

- Chapter 3: Designing a Cylindrical Shell Roof

- Chapter 4: Master Lesson: Designing a Trussed Roof

- Chapter 5: Building on a Vertical Site

- Chapter 6: Designing with Multipanel Trusses

- Chapter 7: Designing a Fanlike Roof

- Chapter 8: Designing Unreinforced Masonry

- Chapter 9: Master Lesson: Designing a Concrete Shell Roof for a Grandstand

- Chapter 10: Designing Efficient Trusses

- Chapter 11: Designing Restraints for Funicular Structures

- Chapter 12: Designing Shell and Membrane Structures

- Chapter 13: Structural Materials

- Chapter 14: Master Lesson: Designing with the Flow of Forces

- Chapter 15: Designing a Bay of Framing

- Chapter 16: Bending Actions on Beams

- Chapter 17: How Beams Resist Bending

- Chapter 18: Bending Resistance in Beams of Any Shape

- Chapter 19: Designing Columns, Frames, and Load-Bearing Walls

- Chapter 20: Designing a Sitecast Concrete Building

- Chapter 21: Master Lesson: Designing in Precast Concrete

- Chapter 22: Designing an Entrance Canopy

- Afterword: Engineers and Architects

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Form and Forces by Edward Allen,Waclaw Zalewski in PDF and/or ePUB format, as well as other popular books in Architecture & Architecture Design. We have over one million books available in our catalogue for you to explore.