![]()

1

TEXTILE DESIGN AND PRINT IN THE DIGITAL AGE

NEW DIRECTIONS IN TEXTILE DESIGN

As the most significant advance in fabric-printing technology since the invention of the silk screen, digital textile printing is bringing about a revolution in textile design. Designers are seeking inspiration from previously unexplored sources, and a new visual language for surface design is starting to evolve.

The cross-disciplinary use of graphics software, digital photography, video, and special effects by a hybrid generation of young designers is creating a new look for printed fabrics. Fashion designers such as Issey Miyake, Hussein Chalayan, and Comme des Garçons have continued to utilize and adapt digital design and production technologies and are breaking new ground with the creation and use of highly innovative prints that make little reference to traditional patterns: florals have been reinvented through the use of photography, and geometric designs as the focal point of a garment have been given a futuristic edge by designers such as Jonathan Saunders. The process is now widely used in runway fashion collections today, through the use of large engineered or placement prints where the artwork is tailored to fit the structure of the garment. Designers working in other areas such as costume, theater, interior, and product design are also finding it easier to involve themselves in the creation of surface designs for their work. The accessibility of this technology through the use of service bureaus also makes it possible for artists and designers who do not have specialist knowledge of textile printing to design and produce their own fabrics and decorative surfaces.

The use of digital print has rapidly established itself within fashion and textile design, although, due to its high production costs, the major creative developments are to be found in the mid- to high end of the fashion and textile design industry (as demonstrated by the range of examples shown in this chapter). But already it is drawing together disciplines such as textiles, fashion, and interior design, changing the way that designers work. Increasingly, the integration of print is becoming as vital to the designer’s vision as the form of the garment or product itself, due to the immediacy and spontaneity of digital tools.

This chapter looks at the impact of this new technology on textile design and explores the work of both well-known and emerging designers who are using computer-aided design and digital print to their full potential throughout a wide range of applications.

Danish designer Dorte Agergaard places everyday objects in unusual contexts for her furnishing range.

Mark Van Gennip, "Ink Storm" (2008): In this experimental work, the post-print process was interrupted to create an organic digital print.

The design on Trust Fun’s "Glory Scarf Money Bag" was created using fractal software. Each design is a mathematically valid fractal based on a unique equation and cannot be replicated.

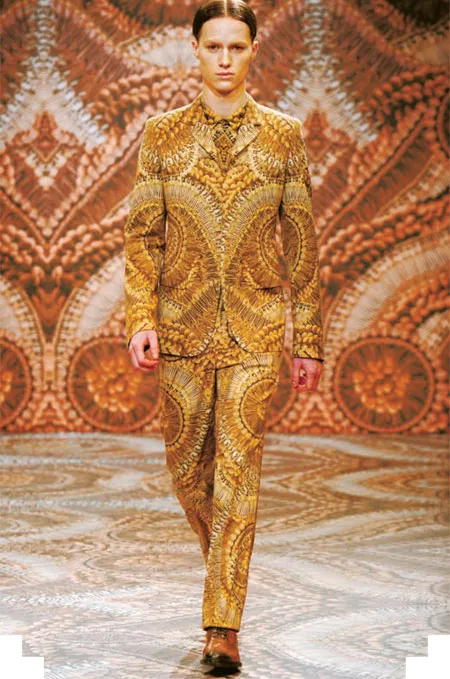

Alexander McQueen, F/W 10: Skulls and bones are the basis for these technically brilliant digital prints, which cover the entire garment.

Basso & Brooke, "Madame Brun," F/W 09: Digital design creates a new contour for the figure.

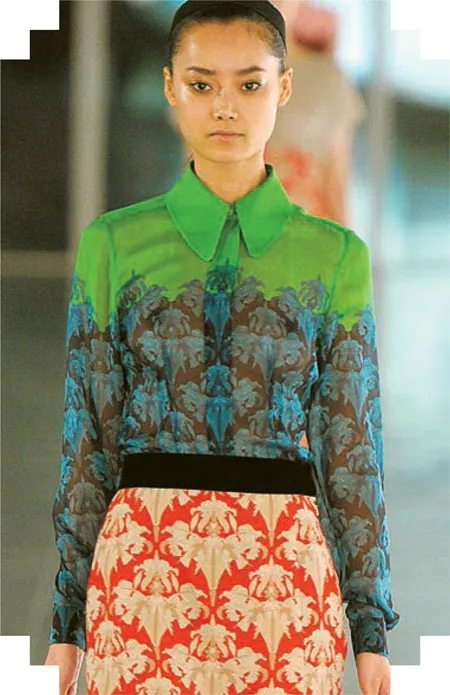

Mary Katrantzou’s S/S 11 trompe l’oeil print collection "This Is Not a Room" creates a three-dimensional interior view with garment shapes inspired by lampshades and fringing.

Jonathan Saunders’s F/W 11 collection, inspired by 1940s art deco design, features an elegant and sophisticated use of digital design and print.

DIGITAL TEXTILE PRINTING

The digital printing of textiles grew out of reprographic technologies originally developed for paper and signage printing, and it now offers the same advantages to the textile industry that digital production affords the paper- and bannerprinting businesses. For individual designers and hobbyists it is analogous to the rise of desktop publishing, albeit more costly. Technology was slower to emerge in the textile industry because of the need to develop suitable inks and large-format printers specifically designed to accommodate woven as well as stretchable cloth. With the emergence of large-format digital textile printers, such as the Mimaki in 1998, and then the release of industrial-scale printers in 2003 by companies such as Konica, Minolta, Reggiani, Robustelli, and Dupont, there is now the potential for major changes in the textile and fashion industries in terms of increased speed and long run capability. The introduction of the Isis printer by Osiris in 2008 means that the speed of inkjet printing machines may begin to rival that of traditional rotary screen printing.

Digital printing has perhaps four main advantages over traditional printing: speed of translation of the design onto the fabric; the ability to print intricate details and millions of colors; the possibility of producing very large-scale images; lessened impact on the environment. Traditional methods of printing based on processes similar to stenciling—including silk screen, woodblock, and gravure—first require that a separate template for each color be made, and for the image to then be built up in stages as each color must be laid down separately. The more colors, the more expensive and time consuming the process, so the number of colors is limited by practical considerations, often placing considerable restraints upon the designer. Repeated patterns are the norm in industrialized traditional textile printing, and very large-scale images are also impractical as the size of the design is constrained to the exact measurements of the template.

Digital printing means that there is virtually no limit to the kinds of images that may accurately be reproduced using inkjet technology. It is this exciting advantage that has paved the way for the new styles of design that are explored in this chapter.

Prada’s S/S 10 ready-to-wear collection featuring faded postcard beach scenes evoked the nostalgia of summer holidays.

Hussein Chalayan’s S/S 09 collection was based on crushed cars, meticulously painted and then digitally printed to retain the painted detail.

Christopher Kane's 2011 Resort collection takes to the skies with this "Galaxy" print dress.

A NEW VISUAL LANGUAGE

Historically, the introduction of new technology does not usually result in an immediate change in design styles. Initially, design for any industrial application continues to follow the style associated with the preceding technology; the first automobiles, for example, were designed to resemble horsedrawn carriages. Change only begins to occur once practitioners come to understand the potential of a new technology and are comfortable with it.

Heat-transfer printing aside, the introduction of inkjet printing for textiles has meant that textile designers are now able to catch up with graphic designers by exploring the possibilities of computer-aided design (CAD). The early design styles that resulted from the introduction of digital imaging were often obviously computer-generated; the focus was on displaying technology for its own sake rather than using CAD as a tool for achieving a more sophisticated visual effect. A more mature style of digital textile design is now evolving due to increased experimentation by designers, who are creating designs based on scanned or digitally photographed subjects, facilitating effects such as trompe l’oeil as well as graphic and illustrative styles that are only possible using computerized drawing and manipulation tools. Designers are also beginning to combine digital print with traditional techniques to create a new digital craft, which is explored in Chapter Five.

DIGITAL SURFACE DESIGN ...