Improving the Safety and Quality of Eggs and Egg Products

Egg Safety and Nutritional Quality

F Van Immerseel, Y Nys, M Bain, F Van Immerseel, Y Nys, M Bain

- 448 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Improving the Safety and Quality of Eggs and Egg Products

Egg Safety and Nutritional Quality

F Van Immerseel, Y Nys, M Bain, F Van Immerseel, Y Nys, M Bain

About This Book

Eggs are economical and of high nutritional value, yet can also be a source of foodborne disease. Understanding of the factors influencing egg quality has increased in recent years and new technologies to assure egg safety have been developed. Improving the safety and quality of eggs and egg products reviews recent research in these areasVolume 2 focuses on egg safety and nutritional quality. Part one provides an overview of egg contaminants, covering both microbial pathogens and chemical residues. Salmonella control in laying hens is the focus of part two. Chapters cover essential topics such as monitoring and control procedures in laying flocks and egg decontamination methods. Finally, part three looks at the role of eggs in nutrition and other health applications. Chapters cover dietary cholesterol, egg allergy, egg enrichment and bioactive fractions of eggs, among other topics.With its distinguished editors and international team of contributors, Volume 2 of Improving the safety and quality of eggs and egg products is an essential reference for managers in the egg industry, professionals in the food industry using eggs as ingredients and all those with a research interest in the subject.

- Focuses on egg safety and nutritional quality with reference to egg contaminants such as Salmonella Enteritidis

- Chapters discuss essential topics such as monitoring and control procedures in laying flocks and egg decontamination methods

- Presents a comprehensive overview of the role of eggs in nutrition and other health applications including dietary cholesterol, egg allergy, egg enrichment and bioactive fractions of eggs

Frequently asked questions

Information

Microbiology and safety of table eggs

Abstract:

1.1 Introduction

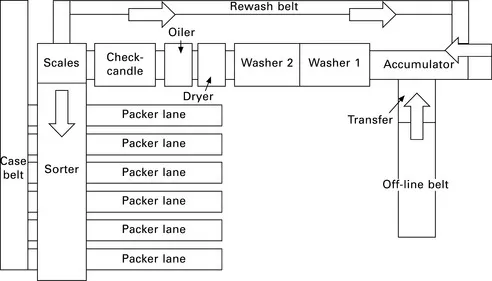

1.1.1 United States table egg industry