![]()

Section One – Advances in Quality Control,

Market and Consumer Demand

![]()

CHAPTER 1

Rheological Properties of Tomato Products

MIRIAM T. K. KUBO, MELIZA L. ROJAS, ALBERTO C. MIANO AND PEDRO E. D. AUGUSTO*

University of São Paulo (USP), Luiz de Queiroz College of Agriculture (ESALQ), Department of Agri-food Industry, Food and Nutrition (LAN), Piracicaba, SP, Brazil

*Email:

[email protected]1.1 Introduction

Rheology is the science that studies the flow and deformations of materials when they are subjected to mechanical forces. Rheological study of food is necessary for the determination of engineering parameters, design of manufacturing machineries and unit operations, quality control and product development, definition of packaging and storage strategies, and more.1–3 Knowledge of rheological behavior is required all the way from manufacturing to product consumption. Consistency and mouthfeel are particularly valuable attributes in tomato products, highlighting the importance of rheology in sensory quality and consumer acceptance.

Fluid foods exhibit a wide variety of rheological behavior, ranging from Newtonian to time-dependent and viscoelastic.2 Since most tomato products are dispersions composed of suspended particles (pulp) and aqueous medium (serum), the content and characteristics of both phases play an important role in the complex rheology of tomato products. By causing structural and physicochemical changes in pulp and serum, food processing and its conditions consequently affect the rheological properties of the product as well.

In this chapter the principles of rheology, including the description of fundamental concepts and classification of fluids, are introduced. In addition, steady-state shear, time-dependent, and viscoelastic properties are described. Each is discussed separately, showing examples of tomato products and presenting the equations and their respective parameters usually employed to model the rheological behavior. Further, the influence of product composition, processing conditions, and operations on these properties is also discussed.

1.2 Fundaments of Rheology

Rheology studies the deformation and flow of materials subjected to mechanical forces. Depending on the material characteristics and the mechanical events, different rheological properties are obtained. The determination of rheological properties of food is important because they are useful for studying food quality and for designing equipment and food processing. In addition, the rheological parameters are crucial for calculating unit operations that involve phenomena not only of momentum transfer, but also of heat and mass transfer.

The rheological properties are determined by studying the deformation of the material during the application of a stress (σ), or vice versa. The stress consists of applying a force (F) in a determined superficial area (A). Many types of stresses can be applied, depending on the food characteristics and processing, thus leading to different analyses.

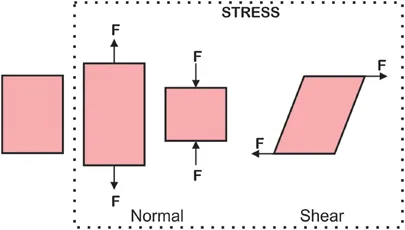

For instance, in solid materials (Figure 1.1), normal stress (uniaxial compression or extension, where the applied force is perpendicular to the cross-section) or shear stress (where the applied force is parallel to the cross-section) can be applied. In fact, pure solid materials have elastic behavior, which means that when a stress applied to the solid is released, the solid recovers its shape from any deformation. However, “solid” foods do not behave either as a pure solid or as a pure fluid: they have an intermediate behavior known as viscoelastic behavior.

Figure 1.1 Types of stress (σ) applied to solids.6

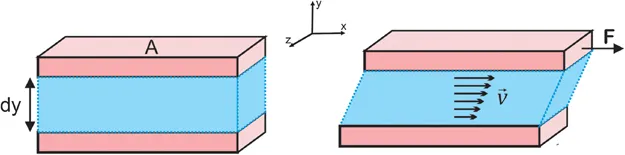

The rheological properties of fluids are commonly evaluated by applying shear stress. Figure 1.2 illustrates an ideal experiment where a fluid sample is in contact with two parallel slabs of known area A separated by a distance dy. While one slab is fixed, the other one moves at constant velocity v due to an applied force F. The fluid layer close to the upper slab will move with the same velocity, while the fluid close to the lower slab will remain at rest. Therefore, when the steady-state condition is obtained, the fluid will move following a velocity profile in the x direction. In fact, the shear stress can be calculated by eqn (1.1), resulting in a fluid velocity gradient called shear rate (, eqn (1.2)).

The relation between the shear stress and the shear rate gives the information necessary to recognize the type of fluid and its behavior during processing. This is detailed in the following section.

Figure 1.2 Shear deformation of a fluid product. The fluid between two parallel slabs (dy) with area (A) is deformed by a shear stress due to an applied force (F). The velocity of the fluid that is close to the upper slab has a velocity (v), while the fluid close to the lower slab is at rest. This create a velocity gradient ().

1.2.1 Fluid Flow

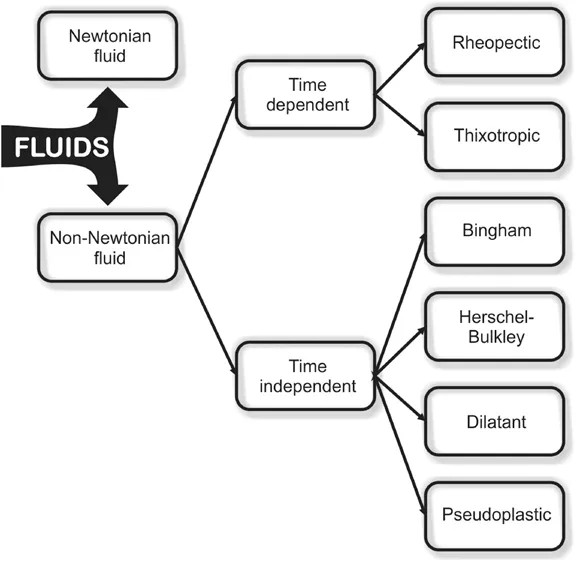

Fluid materials can be classified rheologically according to their flow behavior (Figure 1.3). First, a perfect fluid is one whose shear rate is linearly proportional to the shear stress and whose constant of proportionality is called viscosity (η), which represents the resistance of the fluid to flow. These fluids follow Newton’s law (eqn (1.3)), so they are called Newtonian fluids. Example of Newtonian fluids are air, water, dilute solutions, oil, milk, clarified juices, and the juice serum.

Figure 1.3 Classification of fluids according to their flow behavior.

However, most liquid foods do not follow Newton’s law, due to structural changes during flow. They are known as non-Newtonian fluids, but depending on the fluid, they have different behaviors (Figure 1.3). These fluids can also be classified as time-independent or time-dependent non-Newtonian fluids. Time-dependent means that the fluid structure changes as the flow time increases. For instance, some particles of the fluid may aggregate to form bigger particles or may be destroyed to form smaller particles during flow, changing the rheological behavior as the fluid flows.3,4

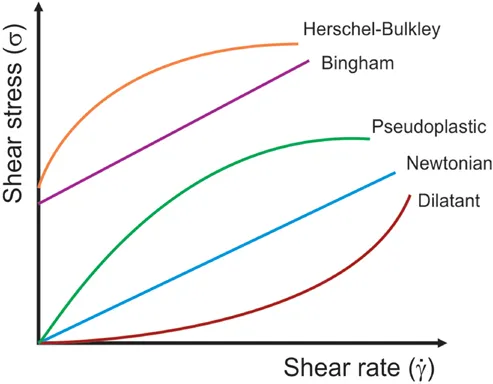

Time-independent non-Newtonian fluids can usually present four different behaviors: dilatant, pseudoplastic, Bingham, and Herschel–Bulkley (Figure 1.4). In most of these fluids, the “viscosity” is not a constant property in relation to the shear rate. This property is therefore known as apparent viscosity, as its value is a function of the shear rate.

Figure 1.4 Classification of fluids according to their shear stress/shear rate relationship.

Dilatant fluids, or shear-thickening fluids, are characterized by an increase in apparent viscosity as the shear rate increases. Examples are concentrated suspensions of starch in water, crystalized honey, and suspensions of sand in water. This...