eBook - ePub

Theory of Flame Retardation of Polymeric Materials

Li Jianjun, Ou Yuxiang

This is a test

Partager le livre

- 288 pages

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

eBook - ePub

Theory of Flame Retardation of Polymeric Materials

Li Jianjun, Ou Yuxiang

Détails du livre

Aperçu du livre

Table des matières

Citations

À propos de ce livre

Flame retardant materials are of vital importance in guaranteeing personal security. Especially the demand for non-toxic, low smoking, polymerized flame retardants increases and new materials enter the market. The authors present the fundamental theory of polymer combustion, compare different flame retardants, describe smoke suppression mechanisms, and explain analyzing techniques for new materials.

Foire aux questions

Comment puis-je résilier mon abonnement ?

Il vous suffit de vous rendre dans la section compte dans paramètres et de cliquer sur « Résilier l’abonnement ». C’est aussi simple que cela ! Une fois que vous aurez résilié votre abonnement, il restera actif pour le reste de la période pour laquelle vous avez payé. Découvrez-en plus ici.

Puis-je / comment puis-je télécharger des livres ?

Pour le moment, tous nos livres en format ePub adaptés aux mobiles peuvent être téléchargés via l’application. La plupart de nos PDF sont également disponibles en téléchargement et les autres seront téléchargeables très prochainement. Découvrez-en plus ici.

Quelle est la différence entre les formules tarifaires ?

Les deux abonnements vous donnent un accès complet à la bibliothèque et à toutes les fonctionnalités de Perlego. Les seules différences sont les tarifs ainsi que la période d’abonnement : avec l’abonnement annuel, vous économiserez environ 30 % par rapport à 12 mois d’abonnement mensuel.

Qu’est-ce que Perlego ?

Nous sommes un service d’abonnement à des ouvrages universitaires en ligne, où vous pouvez accéder à toute une bibliothèque pour un prix inférieur à celui d’un seul livre par mois. Avec plus d’un million de livres sur plus de 1 000 sujets, nous avons ce qu’il vous faut ! Découvrez-en plus ici.

Prenez-vous en charge la synthèse vocale ?

Recherchez le symbole Écouter sur votre prochain livre pour voir si vous pouvez l’écouter. L’outil Écouter lit le texte à haute voix pour vous, en surlignant le passage qui est en cours de lecture. Vous pouvez le mettre sur pause, l’accélérer ou le ralentir. Découvrez-en plus ici.

Est-ce que Theory of Flame Retardation of Polymeric Materials est un PDF/ePUB en ligne ?

Oui, vous pouvez accéder à Theory of Flame Retardation of Polymeric Materials par Li Jianjun, Ou Yuxiang en format PDF et/ou ePUB ainsi qu’à d’autres livres populaires dans Technology & Engineering et Materials Science. Nous disposons de plus d’un million d’ouvrages à découvrir dans notre catalogue.

Informations

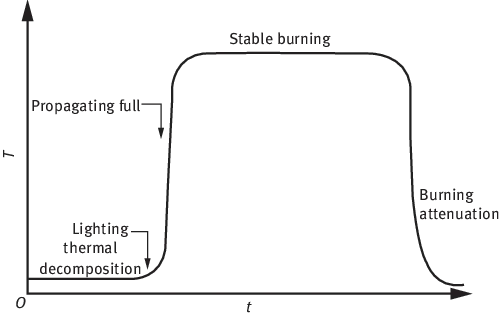

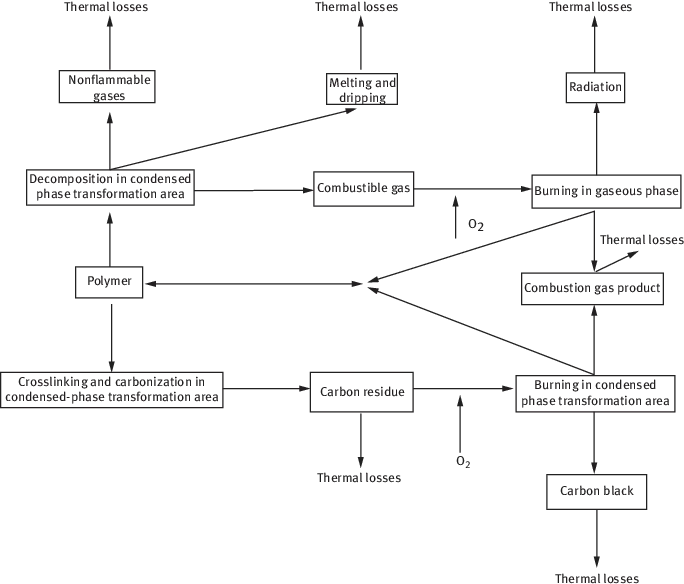

Generally speaking, the combustion process of polymers can be divided into five stages (Figure 1.1) [1] in time, which includes thermal decomposition, ignition, propagation, stable combustion and combustion attenuation. At the same time, these five stages can also be separated in space, such as surface-heating area, condensed phase transformation area (decomposition, crosslinking, carbonization) and vapor-phase combustible combustion area. Figure 1.2 shows the unit model of polymer combustion [2].

Figure 1.1: Five stages of polymer combustion [1].

Due to their characteristics, there will be some special thermal behaviors of polymer during the heating procedure, such as glass transitions, softening, melting, expansion, foaming, shrinkage, etc [3].

In this chapter, we will not only explain the five stages of polymer combustion but also analyze the smoke, toxic and corrosive products produced during the combustion procedure to provide some theoretical foundations for the discussion of the flame-retardation mechanisms of polymers.

1.1 Thermal decomposition

1.1.1 Overview

When the thermoplastics were heated, evaporation and pyrolysis of the solid phase were considered to be confined to a thin layer, namely condensed-phase/vapor-phase interface. Generally, when the polymer is heated, it will be first thermally degraded into pieces or monomers or fragments with low-molecular weight, and the escape rate of the latter is concerned with the mass transfer process [4, 5].

Figure 1.2: Unit model of polymer combustion [2].

The thermal decomposition of polymers is the first step for the cause and development of combustion, and it is very important for estimating the reaction of materials to fire, synthetizing heat-resistant polymer and recycling waste polymer.

When an external heat source is put on the material, the material temperature gradually rises. An external heat source may be produced directly from the flame (by radiation and convective heat transfer), the hot vapor (by conduction and convection heat transfer) and the hot solid material (by heat conduction). When heated, heating rate of material not only depends on external heat flow rate and temperature difference but also is related to specific heat capacity, thermal conductivity and carbonization, evaporation and other changing latent heat of the material.

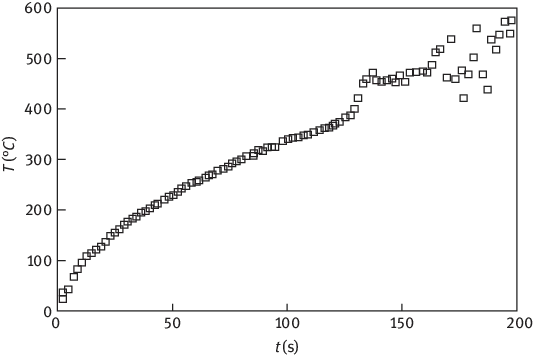

Under the intense radiation near the hot objects, the surface of polymer will be heated rapidly, and its temperature rises with the square root of thermal radiation time. Taking polyethylene (PE) as an example, when the radiation intensity is 36 kW/M2 (which is equal to the blackbody temperature of 613 °C), its surface temperature rising based on time is shown in Figure 1.3 [6].

Figure 1.3: Relationship between polyethylene surface temperature and time [6] under a radiation intensity of 36 kW/M2.

If the radiation intensity is low, the highest surface temperature of polymer would not be enough to ignite polymer, as well as would have low thermal diffusivity and thin thermal layer. Thus, polymer is difficult to be ignited (the ignition temperature of polymethyl methacrylate [PMMA] is 250–350 °C, whereas that of PE is 330–370 °C), and only thermal decomposition will occur [7].

When the temperature of polymer rises up to a certain level, it begins to degrade, and the initial temperature of degradation is usually the temperature of bond rupture that has the worst thermal stability. During this period, polymer could still be intact, but the weakest bond ruptures often change the color and luster of polymers. There are two forms of degradation: nonoxide degradation and oxidative degradation. The former occurs without oxygen, whereas the latter should be heated and degraded with oxygen. Proportion of the most volatile decomposition temperature of the bonds and the instability of bonds in polymer are closely related to the degradation of polymer.

When most bonds rupture due to polymer decomposition, it enables a long chain of 104–105 carbon atoms to be decomposed into low molecular product. Then, the molecular weight of polymer gets smaller dramatically, polymer itself also begins to change, and this change can lead to a complete loss on its physical integrity or generate new substance with different properties, most of which are compounds with low molecular weight and many of these compound are inflammable materials, which can also volatilize into the vapor phase, thus reducing the total weight of polymer. For example, when thermal decomposition occurs, polyformaldehyde (POM) or PMMA can be decomposed into monomer formaldehyde or methyl methacrylate, respecti...