Pump Wisdom

Essential Centrifugal Pump Knowledge for Operators and Specialists

Robert X. Perez, Heinz P. Bloch

- English

- ePUB (adapté aux mobiles)

- Disponible sur iOS et Android

Pump Wisdom

Essential Centrifugal Pump Knowledge for Operators and Specialists

Robert X. Perez, Heinz P. Bloch

À propos de ce livre

Pump Wisdom

Explore key facets of centrifugal pump ownership, installation, operation, and troubleshooting

The Second Edition of Pump Wisdom: Essential Centrifugal Pump Knowledge for Operators and Specialists delivers a concise explanation of how pumps function, the design specifications that must be considered before purchasing a pump, and current best practices in lubrication and mechanical seals.

Readers will encounter new startup and surveillance tips for pump operators, as well as repair versus replacement or upgrade considerations for maintenance decision makers, new condition monitoring guidance for centrifugal pumps, and expanded coverage of operator best practices.

This latest edition of Pump Wisdom: Essential Centrifugal Pump Knowledge for Operators and Specialists includes expanded coverage of areas critical to achieving best-in-class pump reliability, including commonly encountered issues and easy-to-follow instructions for getting centrifugal pumps to operate safely and reliably.

This book also provides:

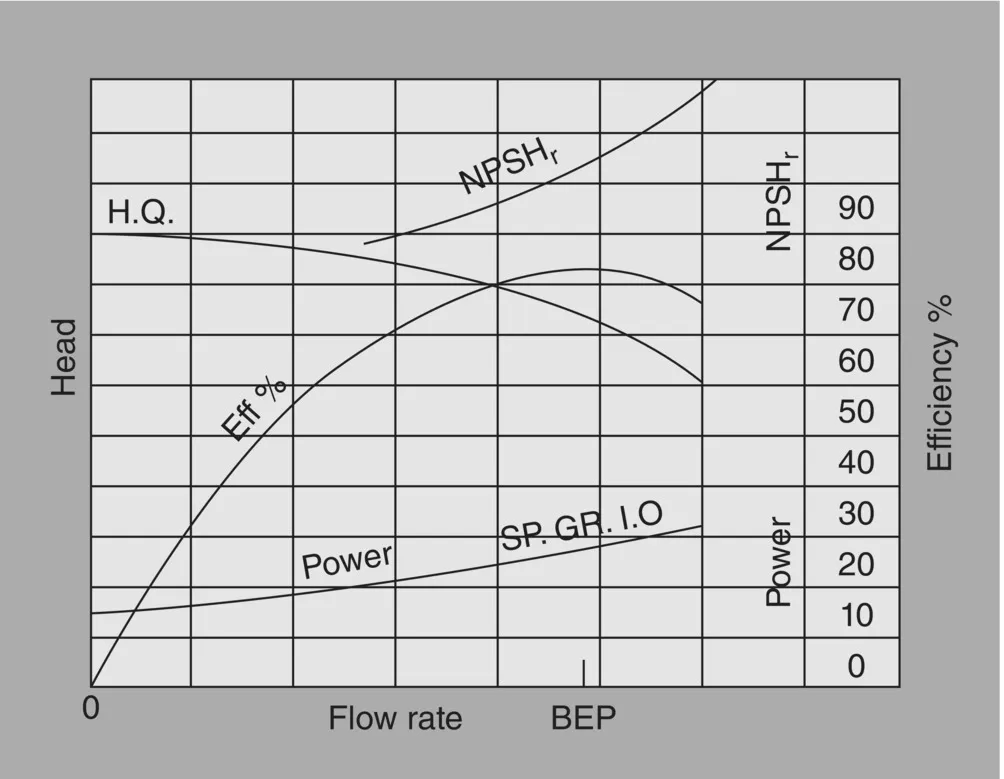

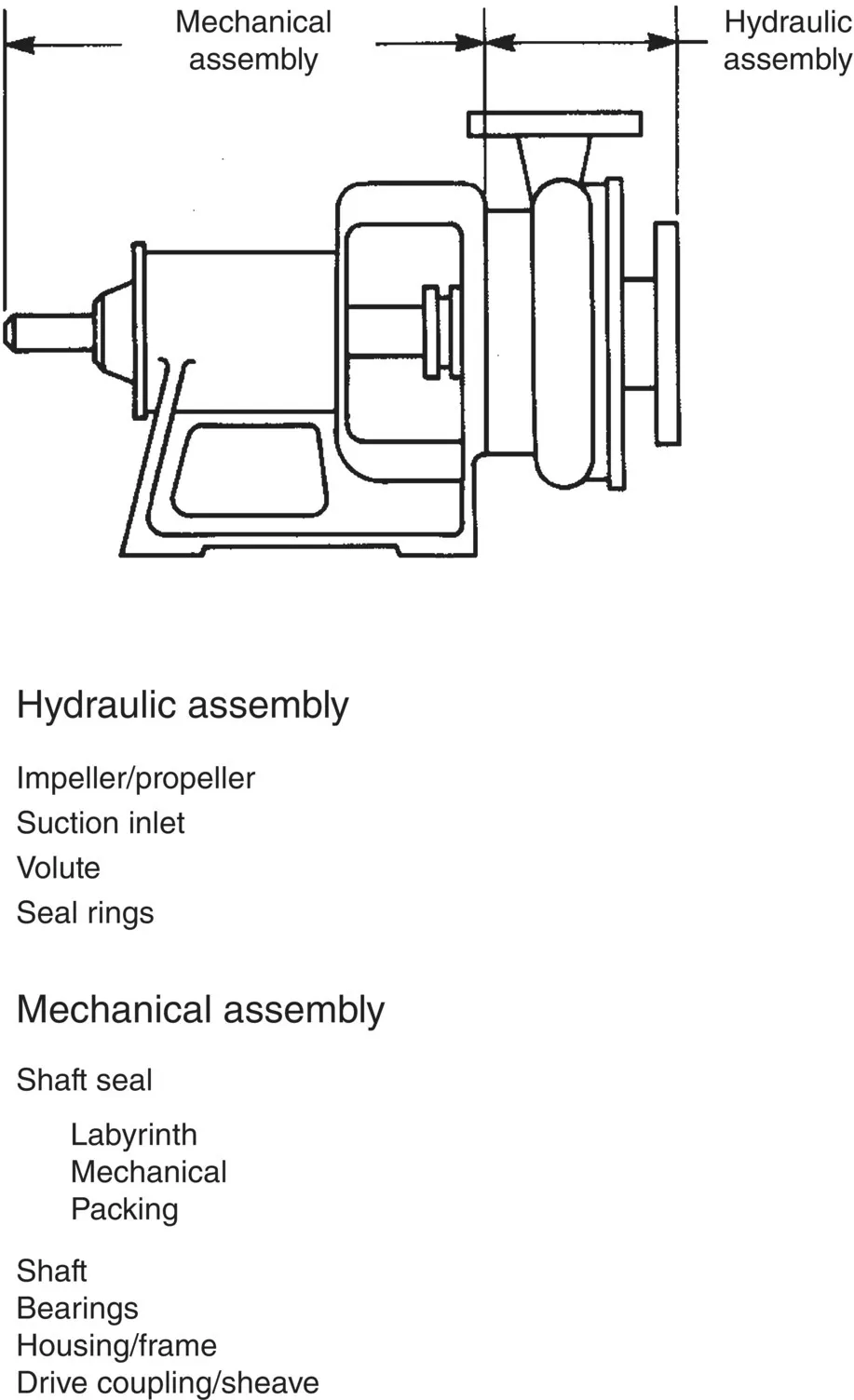

- Comprehensible and accessible explanations of pump hydraulics

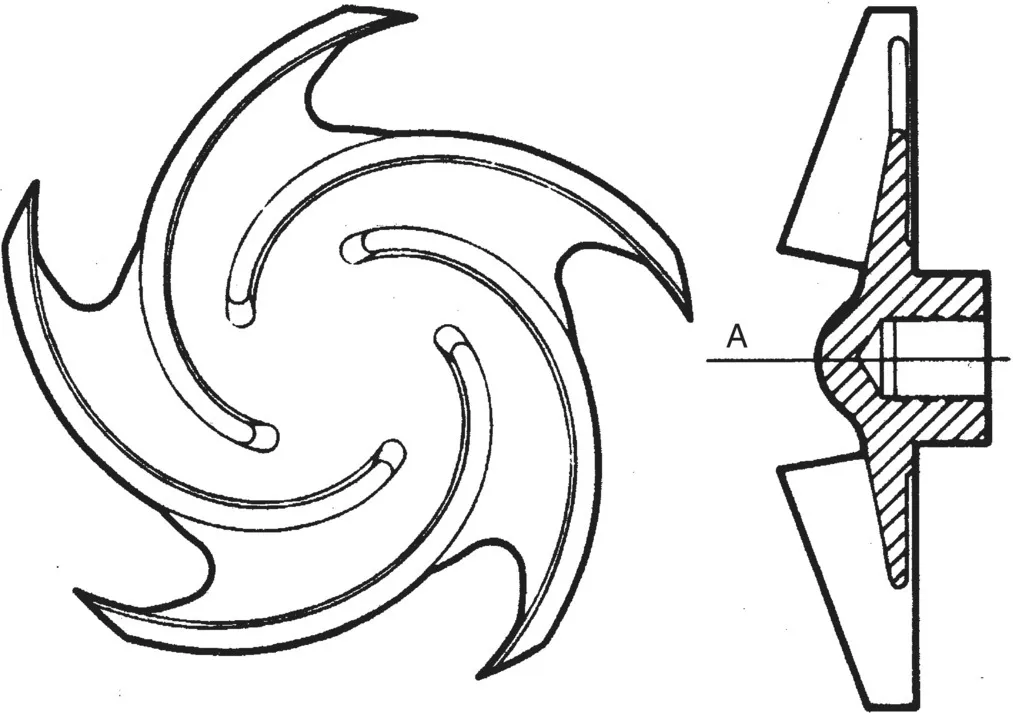

- Simple explorations of the mechanical aspects of pumps with coverage of bearings, seals, impeller trimming, lubricant application, and more

- Safety tips and instructions for centrifugal pumps

Perfect for chemical, petroleum, and mechanical engineers, Pump Wisdom: Essential Centrifugal Pump Knowledge for Operators and Specialists is also an ideal resource for operators, managers, purchasing agents, machinists, reliability technicians, and maintenance workers in water and wastewater plants.

Foire aux questions

Informations

1

Principles of Centrifugal Process Pumps

Pump Performance: Head and Flow